Patents

Literature

211 results about "Chinese meat bun" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Baozi (Chinese: 包子), or bao, is a type of filled bun or bread-like (i.e. made with yeast) dumpling in various Chinese cuisines. There are many variations in fillings (meat or vegetarian) and preparations (usually steamed).

Pre-fermented frozen dough steamed bread and production method thereof

InactiveCN101744181AUniform colorFlat surfaceDough treatmentPre-baking dough treatmentPotato starchGlutaminase

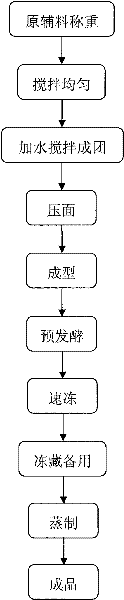

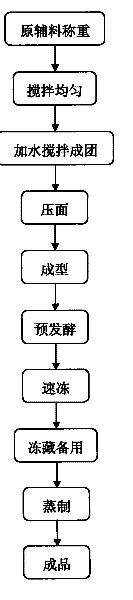

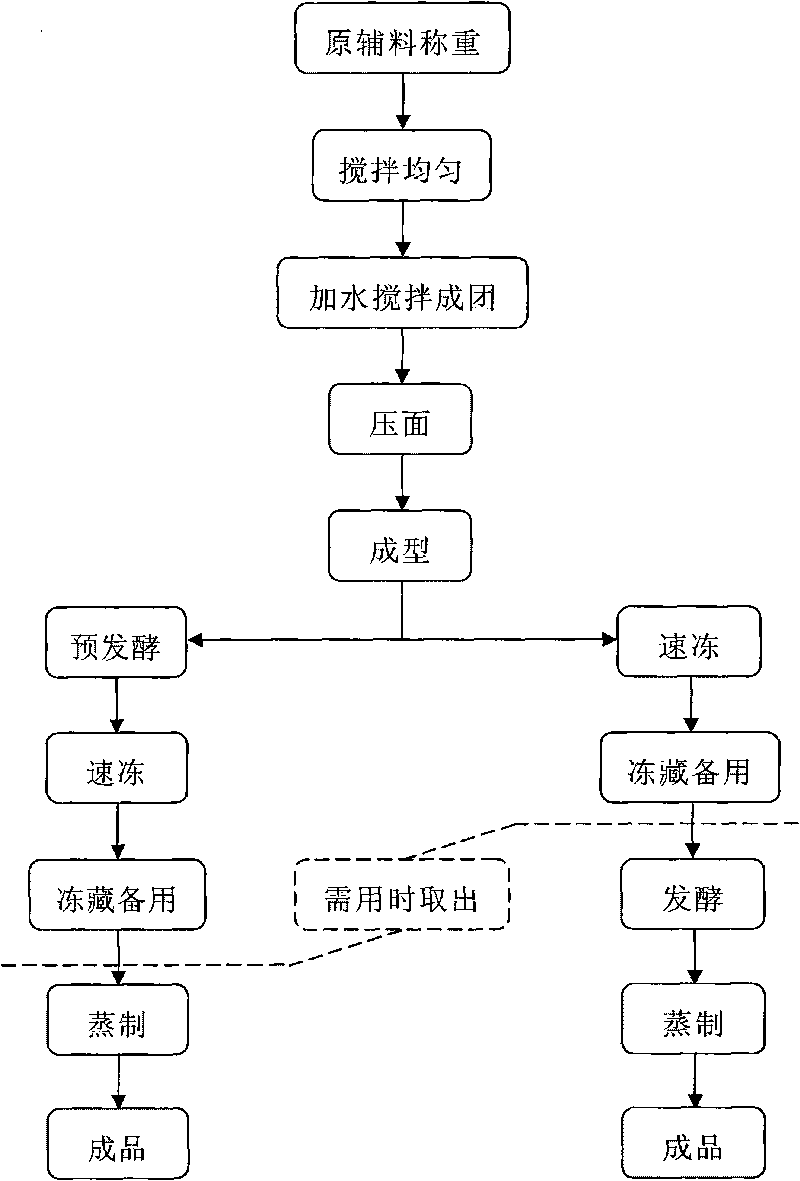

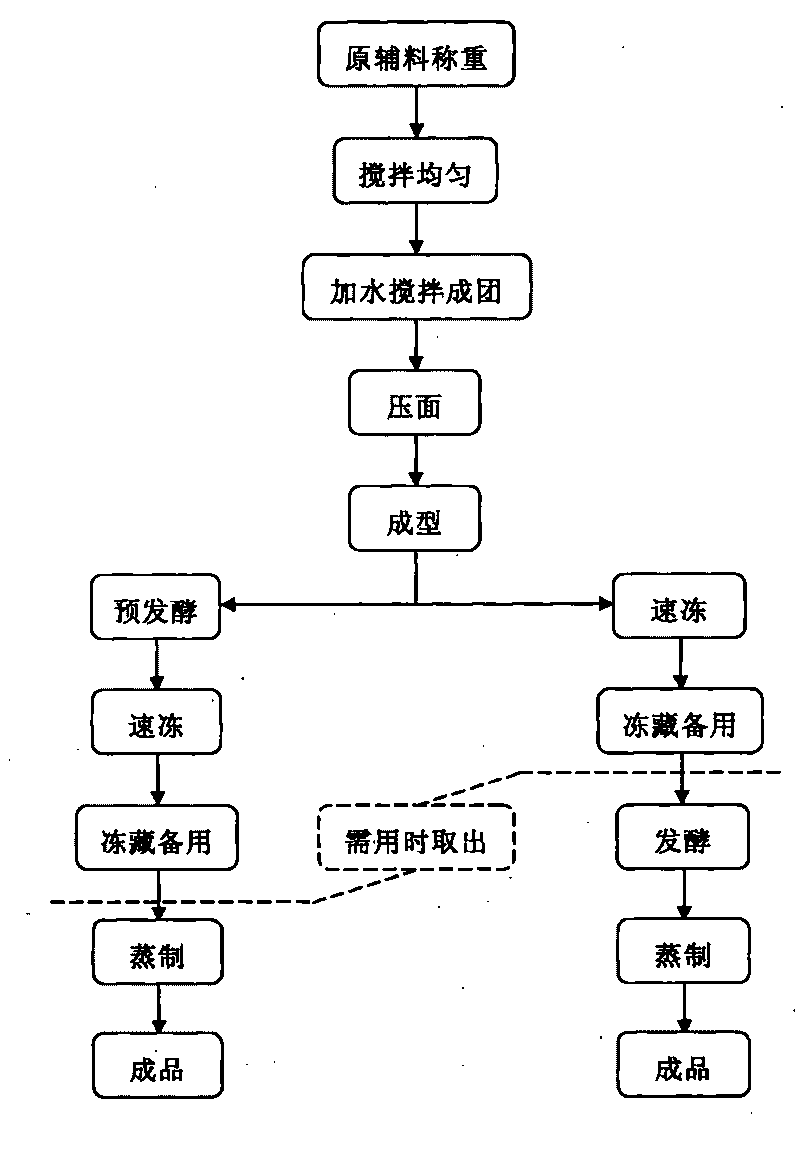

The invention relates to pre-fermented frozen dough steamed bread and a production method thereof, belonging to the technical field of food processing. The production method comprises the following steps: putting flour, Yanshan yeast, non-aluminum baking powder, sugar, shortening, salt, transglutaminase, lipase, xylanase, glucose oxidase, trehalose, ascorbic acid, lecithin, sucrose esters, glycerin, locust bean gum, artemisia gum, carboxymethyl cellulose, guar gum, gluten and wheat starch or corn starch or potato starch or rice starch into a stirring vat, slowly stirring and mixing uniformly, then adding water, and stirring to form dough at a medium speed; pressing the dough, forming, pre-fermented cooling, then quick-freezing, and storing by freezing for standby; and only directly steaming in needing to obtain fresh steamed bread products. The application of the invention overcomes the problem of flavor loss caused by steaming again and keeps the advantages of uniform color, smooth surface, fluffy taste, good flexibility, and the like of steamed bread (steamed stuffed bun) products, and at the same time can improve the standardization, security and convenience of product quality.

Owner:黄卫宁

Chopped meat made from multiple meats, production method and uses thereof

InactiveCN101194729ARich in nutrientsEasy to prepareFood preparationMonosodium glutamateAdditive ingredient

The invention relates to mincemeat which is prepared by various meats and a making method and usage. The main material of mincemeat comprises fish, mutton, pork, chicken, shrimp meat and crab meat, and auxiliary material comprises crab meat, monosodium glutamate, cooking wine, salad oil, aniseed powder, sweet fermented flour sauce, pepper, ginger powder, onion powder and mashed garlic. The process comprises removing bones of meat and fishbone of fish and impurities, then washing and drying, cutting into strips or pieces, removing odor of mutton and fishy smell with tea water, disintegrating all meat in a meat grinder, and fully mixing and stirring with auxiliary material to obtain mincemeat. The mincemeat can be made into ball, pork meat patties according to conventional methods, and also can be used as raw material to make dumplings, Chinese flour dumplings, steamed stuffed bun, meat pie and the like. The invention has the advantage of providing mincemeat prepared by various meats, a making method and usage, which has diversified nutritious compositions, easy processing, delicious taste, and convenient eating.

Owner:蒋越

Preparation method for frozen steamed-stuffed-bun

A preparation method for a frozen steamed-stuffed-bun comprises the following steps: a, stuffing preparation; b, flour mixing; c, dough pressing and preparing; d, fermentation; e, refrigeration; and f, packaging and warehousing. On the basis of inheritance of a conventional fermentation technology, the preparation method is combined with the modern refrigeration technology, and helps to fully guarantee abundance and diversification of the stuffing, so that different demands of the vast number of consumers are satisfied. Because the prepared frozen steamed-stuffed-bun is convenient to preserve, by expanding scale channel of the bun, the frozen steamed-stuffed-bun is conveniently supplied for the consumers; and the frozen steamed-stuffed-bun is convenient to take and is fresh and tasty whenever being taken after directly steamed for 25 minutes.

Owner:杨宝刚

Preparation method of biological preservative farci flour product

ActiveCN101611843ANutrition Security GuaranteeQuality and Safety AssuranceFood preservationBakery product preservationCold chainModified atmosphere

Owner:TIANJIN GOUBULI FOOD

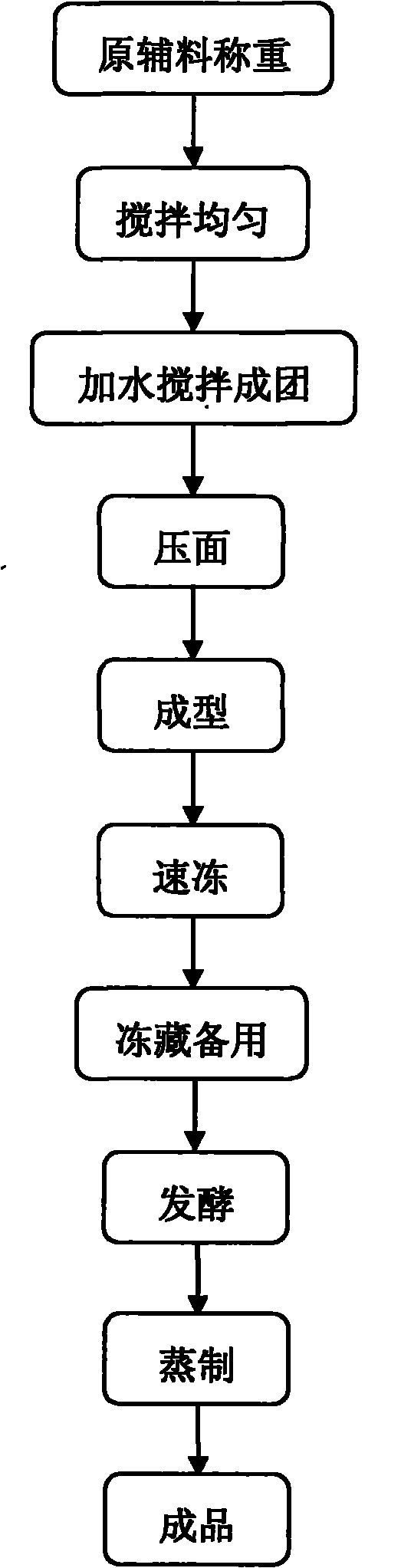

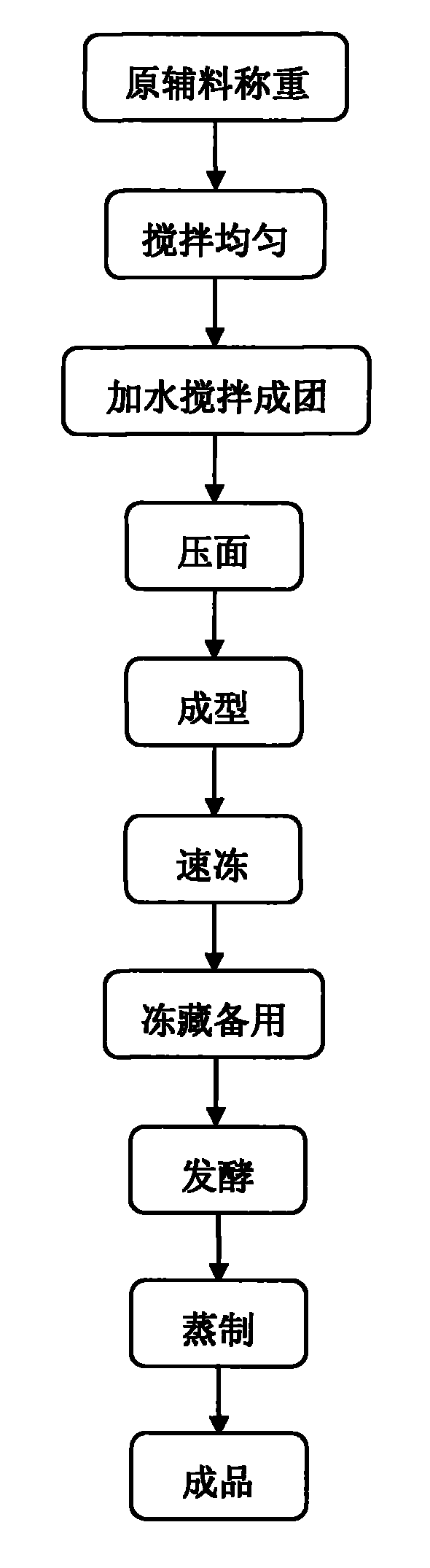

Frozen raw steamed stuffed bun blanks and preparation technology thereof

PendingCN105876625AGreat tasteElastic footFood coatingFood ingredientsFrozen storageAdditive ingredient

The invention relates to the technical field of food processing, and especially relates to frozen raw steamed stuffed bun blanks and a preparation technology thereof. The raw steamed stuffed bun blanks are prepared from the following ingredients in parts by weight: 450-600 parts of flour, 600-850 parts of sour dough, 1-5 parts of semi-dry yeast, 1-4 parts of salt, 12-18 parts of white sugar, 200-300 parts of water, 2-6 parts of a frozen-raw-blank improving agent, 3-8 parts of baking powder and 0.4-1.4 parts of lard. During the dough-making process, the flour, the sour dough, the semi-dry yeast, the salt, the white sugar, the frozen-raw-blank improving agent, the baking powder and the lard are orderly added, mixing and stirring are conducted, so that dough is prepared; and the raw steamed stuffed bun blanks are prepared by wrapping; the shaped raw steamed stuffed bun blanks are quickly frozen in a quick-frozen storage at a temperature of 40 DEG C below zero to 25 DEG C below zero, and the quick freezing is ended when central temperature of the raw steamed stuffed bun blanks reaches 10 DEG C below zero to 25 DEG C below zero; and the quickly frozen raw steamed stuffed bun blanks are stored at a temperature of 5 DEG C below zero to 15 DEG C below zero. The prepared steamed stuffed bun have the advantages of being good in taste, enough in elasticity, free of cracks on surfaces, free of dents in appearance and so on.

Owner:LOUDI SHIDEHUO RESTAURANT MANAGEMENT CO LTD

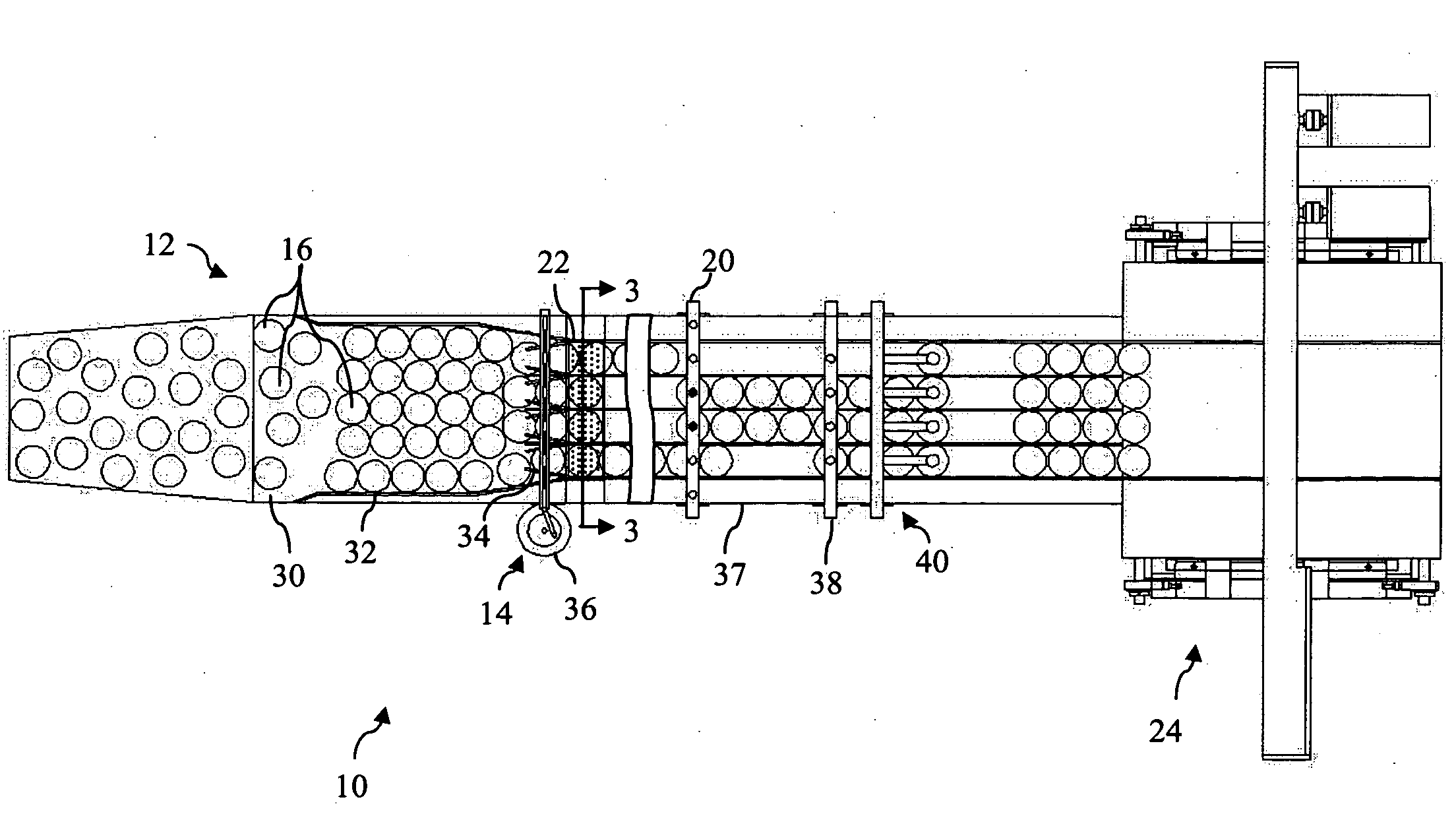

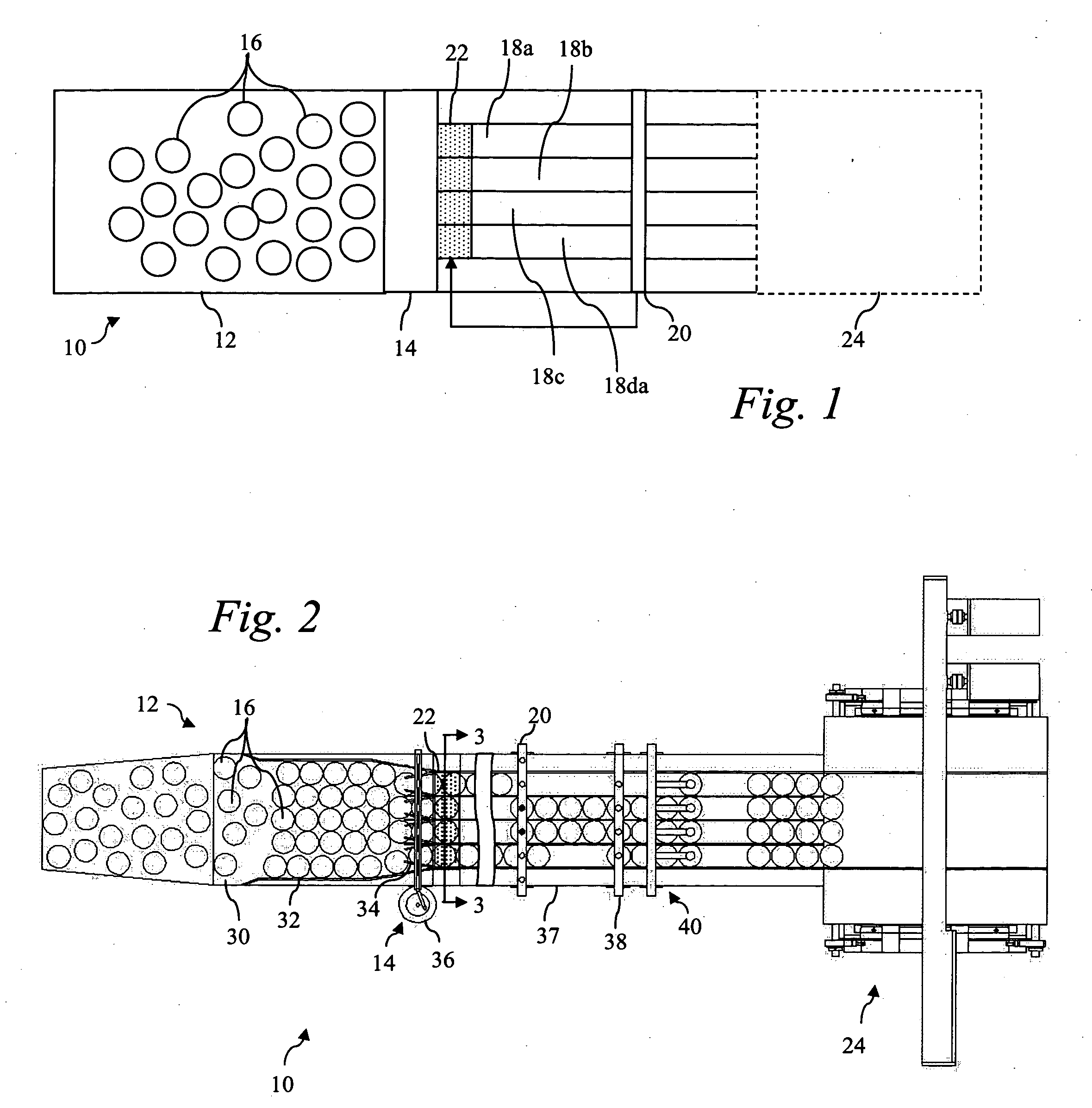

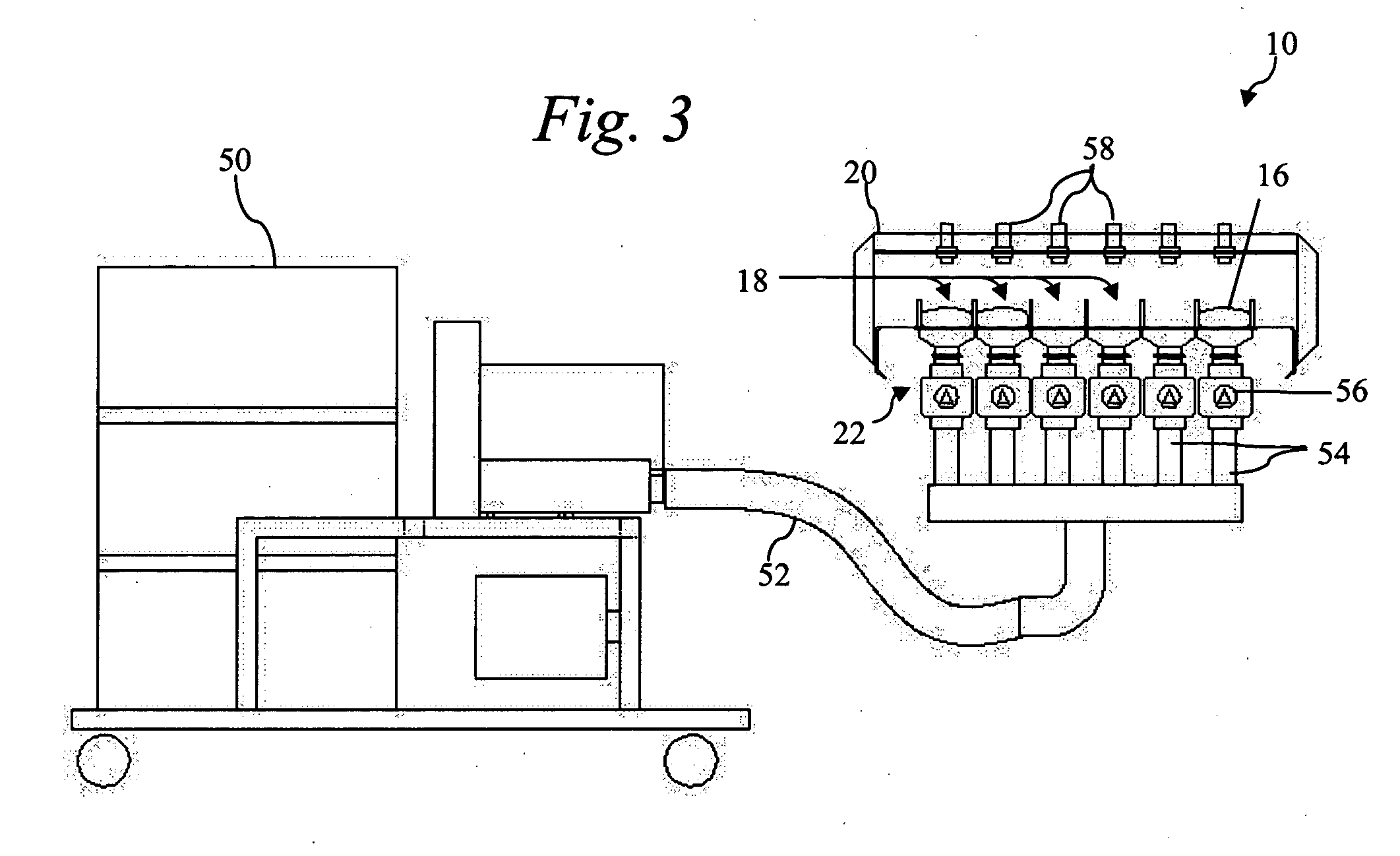

Bun laner

InactiveUS20060070927A1Baked articles handlingControl devices for conveyorsEngineeringChinese meat bun

Owner:HENRY GRP INC THE

Leavening old dough juice, leavening composition and leavening process

InactiveCN102613264ASolve the problem of needing to wake up before steaming pastaShorten the timePre-baking dough treatmentBiotechnologyAlkaline water

The invention relates to the technical field of food making, in particular to leavening old dough juice. The leavening old dough juice is prepared by the following steps of: adding water into old dough, stirring to obtain paste, fermenting at room temperature for 8 to 12 hours, adding flour, water and a swelling agent, stirring uniformly, and fermenting at room temperature for 10 to 15 hours. A leavening composition is prepared from the following raw materials in part by weight: 500 parts of flour, 16 parts of swelling agent, 950 to 1,050 parts of leavening old dough juice, and 5 to 6 parts of alkali. A leavening process comprises the following steps of: dissolving alkali in water to obtain alkaline water, mixing the alkaline water, flour, the swelling agent and leavening old dough juice,adding a proper amount of water, mixing to obtain loose dough, and pressing by using a press flour machine. With the leavening old dough juice, the dough is not required to stand for a certain periodand can be directly steamed, the standing time for the dough is saved, and cooked flour based foods are particularly chewable and good in mouthfeel; and the leavening old dough juice is wide in application range and can be used for fermented flour based foods, such as steamed buns, steamed stuffed buns, steamed twisted rolls and bread which need fermenting.

Owner:范征

Steamed stuffed bun and production method thereof

InactiveCN101422221AAvoid breakingFor long-term storageBakery productsFood preparationDermatologyAir voids

The invention pertains to the technical field of foods, in particular relates to a steamed stuffed-bun and a preparation method thereof. The skin of the steamed stuffed-bun is divided into an external skin and an internal skin, which are mutually jointed, wherein, the external skin is a fermented wrapper and the external skin is a dull wrapper; and stuffing is wrapped in the internal skin. When the steamed stuffed-bun is prepared, the internal skin is put on the external skin at first; then the stuffing is put on the internal skin; the internal skin is intervolved to wrap the stuffing; and finally, the external skin is intervolved to lead the internal skin to be jointed with the external skin and closed. The dull wrapper is also called a fixed wrapper and made by mixing unfermented flour with water. As the dull wrapper has good flexibility and tenacity and great adhesive force and is not easy to be destroyed, spoon meat does not flow out during cooking the steamed stuffed-bun; as the interior of the dull wrapper has no air void and weak adsorption performance, the spoon meat in the stuffing can be well kept in the internal skin and is not be absorbed by the fermented wrapper of the external skin after cooking; therefore, the taste of the steamed stuffed-bun is not affected by long-term storage.

Owner:安徽省高记餐饮管理有限公司

Frozen uncooked steamed stuffed buns and production method thereof

InactiveCN103598508ASimple process100% success rateFood coatingFood shapingProcess engineeringBaking powder

The invention relates to frozen uncooked steamed stuffed buns and a production method thereof. The frozen uncooked steamed stuffed bun comprises a wrapper and stuffing covered in the wrapper, wherein the wrapper is a shell formed by kneading dough, producing a flour sheet and covering the stuffing, and then directly frozen and molded at the temperature in a range from -16 DEG C to -18 DEG C from following raw materials in parts by weight: 4000-6000 parts of flour, 40-60 parts of high-glucose dried yeast, 20-30 parts of table salt, 50-70 parts of baking powder, 40-60 parts of white sugar and 2100-2300 parts of water. According to the method, the steamed stuffed buns are directly frozen in a warehouse after being molded; before the steamed stuffed buns are cooked, one time of fermentation is carried out; the technological process is simple and the success rate is a hundred percent; the mouth feel of a pastry product is guaranteed completely and the nutritional ingredients are not lost so that the uncooked steamed stuffed buns can be on a par with fresh steamed stuffed buns; the problems of large-batch production, storage, distribution and good sale of the steamed stuffed buns can be solved; the frozen uncooked steamed stuffed buns are very suitable for large-scale industrial production.

Owner:罗小勇

Refrigerated dough steamed bread and production method thereof

InactiveCN101773227AUniform colorFlat surfaceDough treatmentPre-baking dough treatmentBiotechnologySucrose

The invention relates to refrigerated dough steamed bread and a production method thereof, which belong to the technical filed of food processing. The method comprises the following steps: firstly, placing flour, yanshan yeast, aluminum-free baking powder, white granulated sugar, shortening oil, salt, transglutaminase, lipase, xylanase, glucose oxidase, trehalose, ascorbic acid, lecithin, sucrose ester, glycerin, locust bean gum, artemisia, carboxymethyl cellulose, guar gum, wheat gluten, wheat starch or cornstarch or potato starch or rice starch into a stirring jar; slowly and uniformly stirring and mixing the mixed materials; then, adding water into the mixed materials for fast stirring to form a dough; then, carrying out dough pressing, forming and quick freezing; next, storing the dough in frozen pack storage for use; taking out the dough when being required; carrying out fermentation; then, steaming the dough; and obtaining fresh steamed bread products. The invention overcomes the problem of flavor loss caused by repeated boiling. When the advantages of uniform color, smooth surface, fluffy mouth feeling, elasticity and the like of the steamed bread (steamed stuffed bun) products are maintained, the product quality standardization, the safety and the convenience can be improved.

Owner:JIANGNAN UNIV

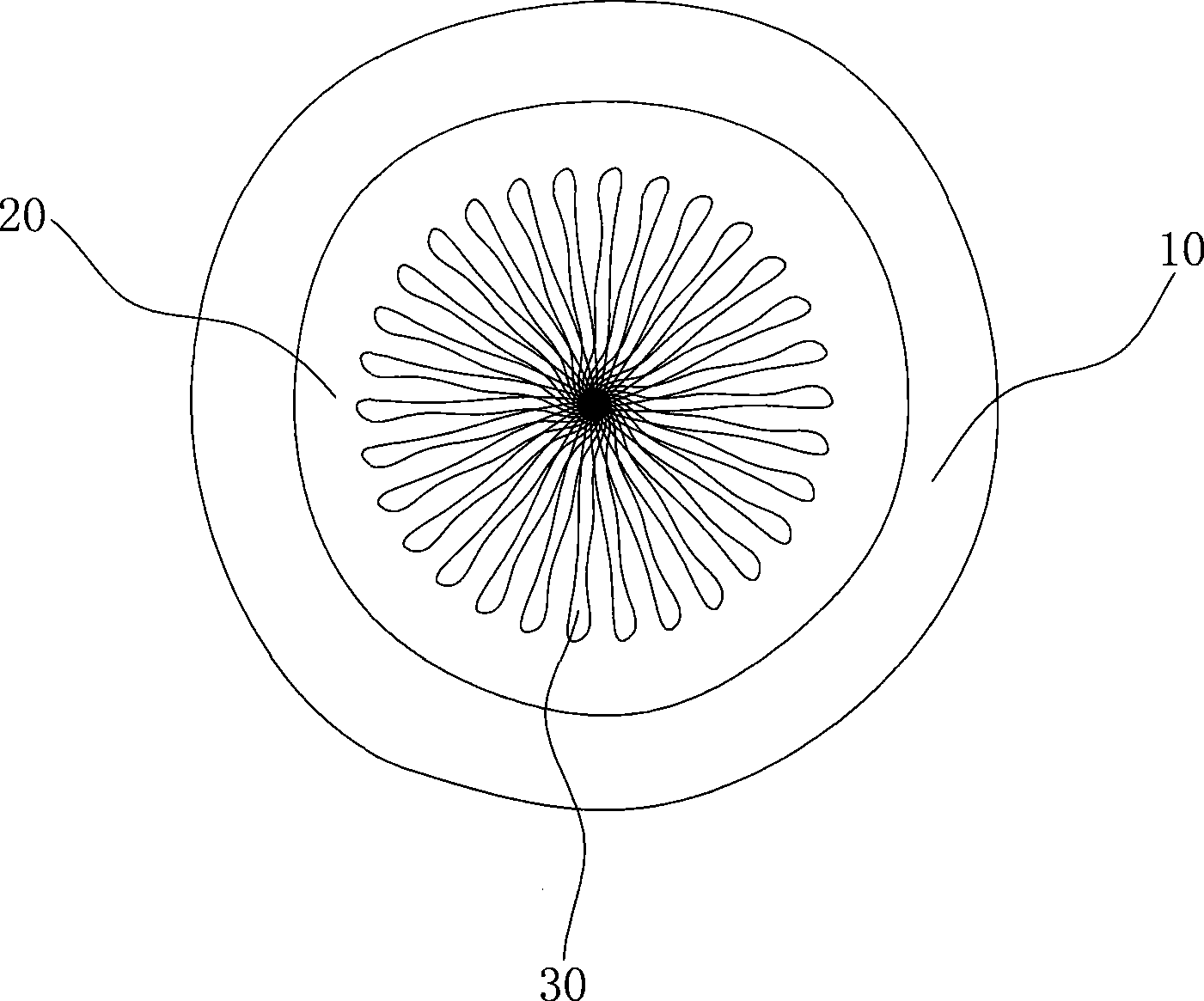

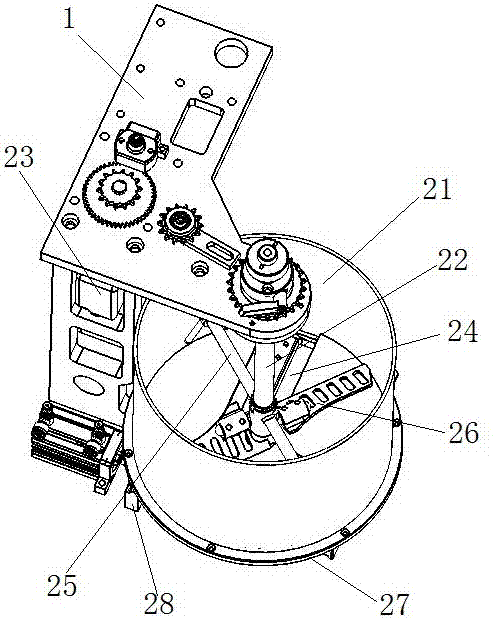

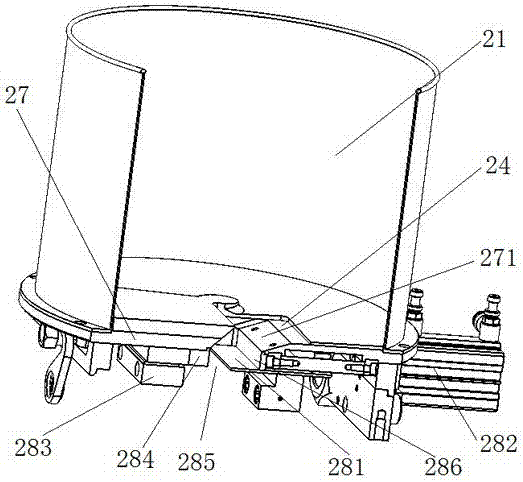

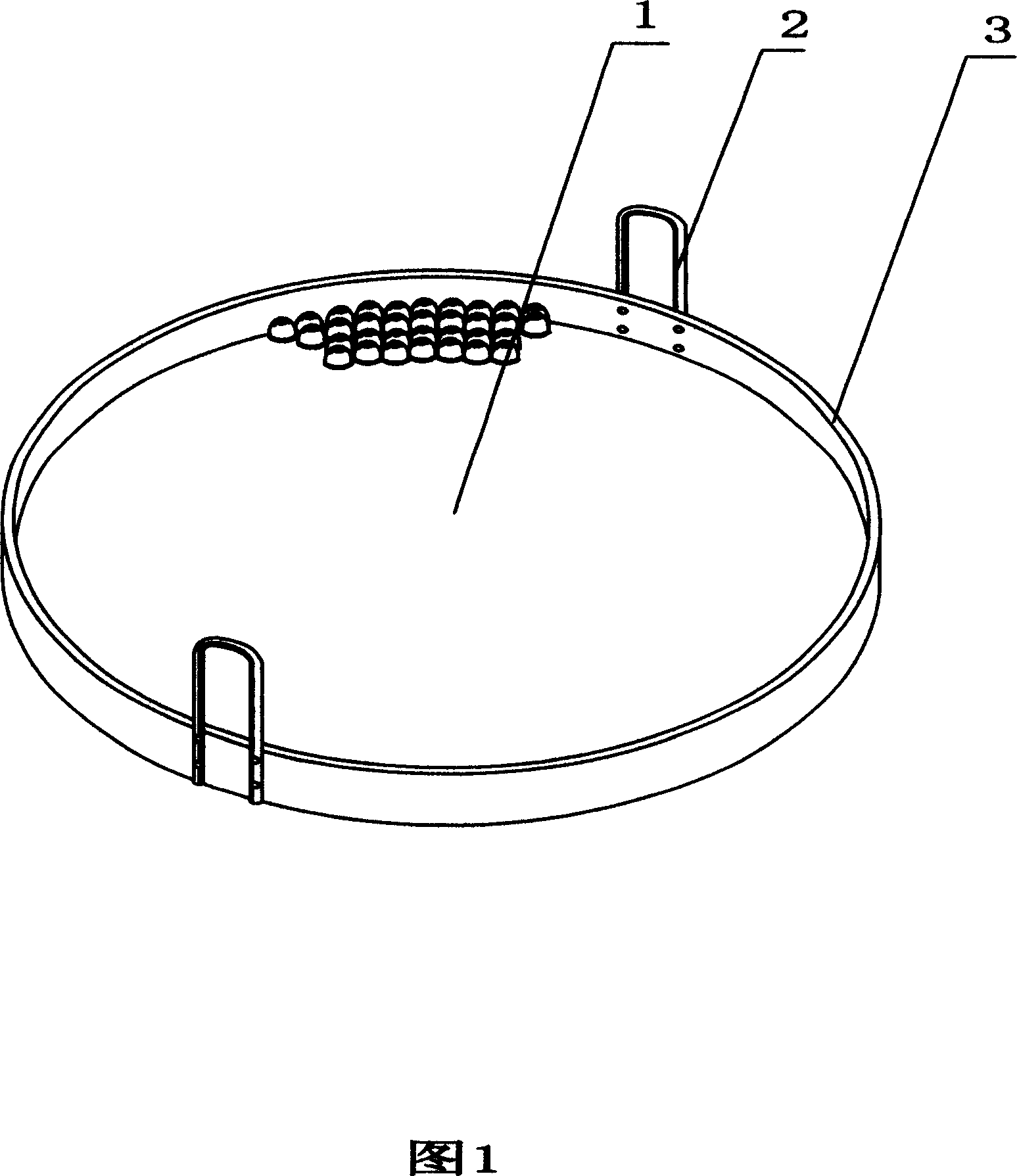

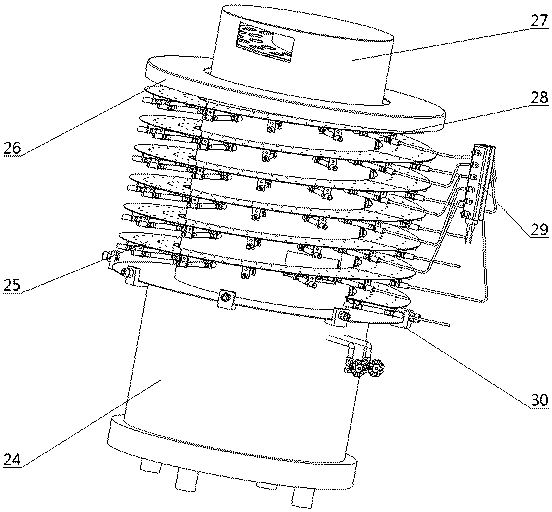

Pattern pinching forming device of steamed stuffed bun machine

ActiveCN107372693AAdjust the amount of fillingOvercoming the lack of stuffing that cannot be adjustedDough processingMachinePower apparatus

The invention provides a pattern pinching forming device of a steamed stuffed bun machine. The pattern pinching forming device comprises a pattern pinching fixing disc, the pattern pinching fixing disc is arranged on a cutter support, is of an annular plate structure and is provided with a pattern pinching cutter block, a downward pattern pinching limiting shaft is arranged in the middle of the pattern pinching cutter block, an inner hole of the annular pattern pinching fixing disc is internally provided with a pattern pinching turntable, the pattern pinching turntable can rotate relative to the pattern pinching fixing disc, and is provided with a pattern pinching limiting slide groove corresponding to the pattern pinching limiting shaft, the pattern pinching limiting shaft is installed in the pattern pinching limiting slide groove in a penetrated mode, the lower end face of the pattern pinching turntable is connected with a pattern pinching power plate, and the pattern pinching power plate is connected with a pattern pinching power device. The pattern pinching forming device is applicable to a simulation steamed stuffed bun machine, can pinch patterns, seal and form fallen cylindrical steam stuffed bun wrappers and seal and pinch the steamed stuffed buns into wrinkles of simulation of manual pinching.

Owner:HENAN WANJIE INTELLIGENT TECH

Quick-frozen leaven-dough steamed stuffed bun and preparation method thereof

The invention relates to a quick-frozen leaven-dough steamed stuffed bun and a preparation method thereof. The quick-frozen leaven-dough steamed stuffed bun is prepared from the following raw materials in parts by weight: 10 parts of yeast, 10 parts of soft sugar, 10 parts of dry ice, 50 parts of lard oil, 10 parts of baking powder, 500 parts of flour and 250 parts of water. The preparation method comprises the following steps: kneading dough, pressing the dough, preparing a wrapper, wrapping stuffing, and freezing for later use; leavening the frozen steamed stuffed bun before steaming for 20 minutes under the conditions that the humidity is 90% and the temperature is 50 DEG C; and ending leavening, putting into a stuffed bun steaming machine, and steaming according to a conventional process. According to the method, the problems of cracks, unleavened dough and reduced volume of the quick-frozen leaven-dough steamed stuffed bun easily caused in the prior art are solved; the success rate is 100%; and the steamed stuffed bun is smooth in surface and good in taste.

Owner:吕文杰

Hot pot baozi and preparation method thereof

The invention discloses a hot pot baozi, which comprises baozi wrappers and stuffing, wherein the baozi wrappers are prepared from the following raw materials: wheat starch, modified starch, water, quick-frozen oil, mycose, sodium stearoyl lactylate, sodium caseinate, and modified soybean lecithin. The stuffing is prepared from the following raw materials: meat, pure fat, dark soy sauce, water, spring onion, water chestnut, agar jelly, salt, white sugar, ground pepper, monosodium glutamate, inosine 5'-monophosphate and guanosine 5'-monophosphate. The invention discloses a preparation method of the hot pot baozi, which comprises the following steps: a) preparing starch gravy; b) adding auxiliary material; c) carrying out vacuum dough making; d) stirring the stuffing; e) molding; f) boiling with water; g) cooling; and i) cold preservation. The hot pot baozi provided with the above-mentioned materials and preparation method has rich nutrition, good taste and good chewing quality. The wrapper of the hot pot baozi has strong toughness, high transparency after water boiling and better retention of cooking liquor. Furthermore, the hot pot baozi has good boiling-resistance and good anti-aging effect.

Owner:WUXI HUASHUN MINSHENG FOOD

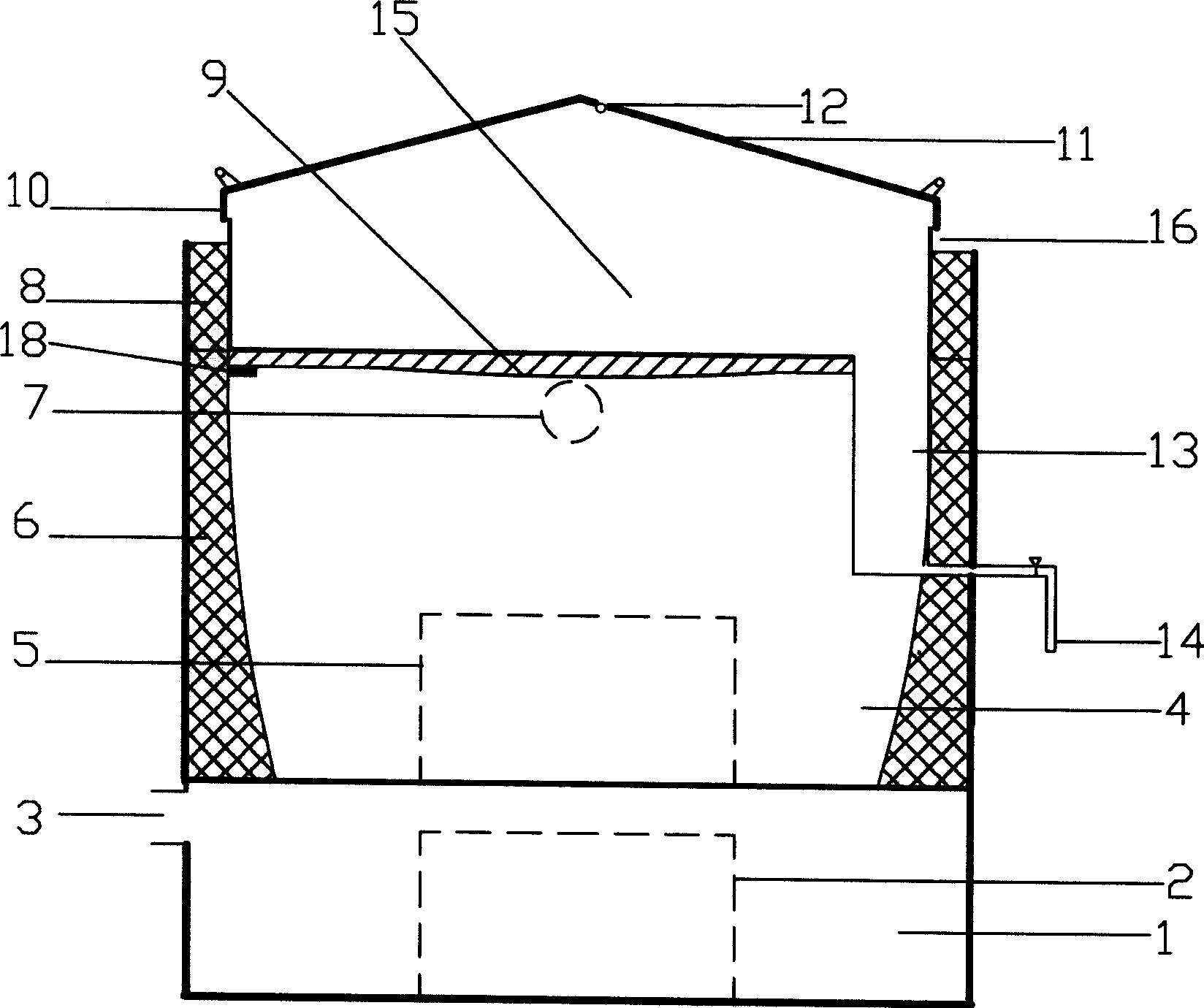

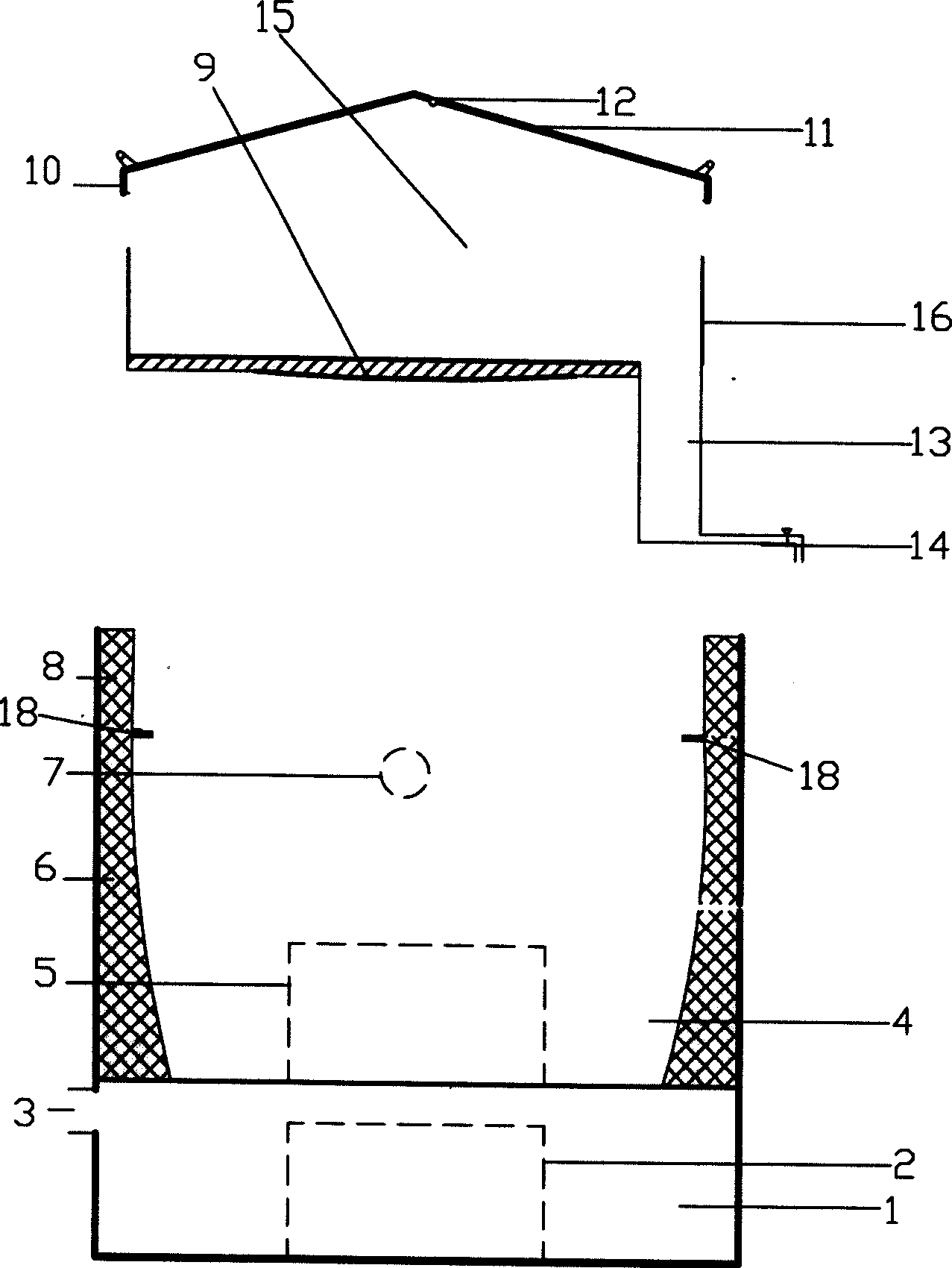

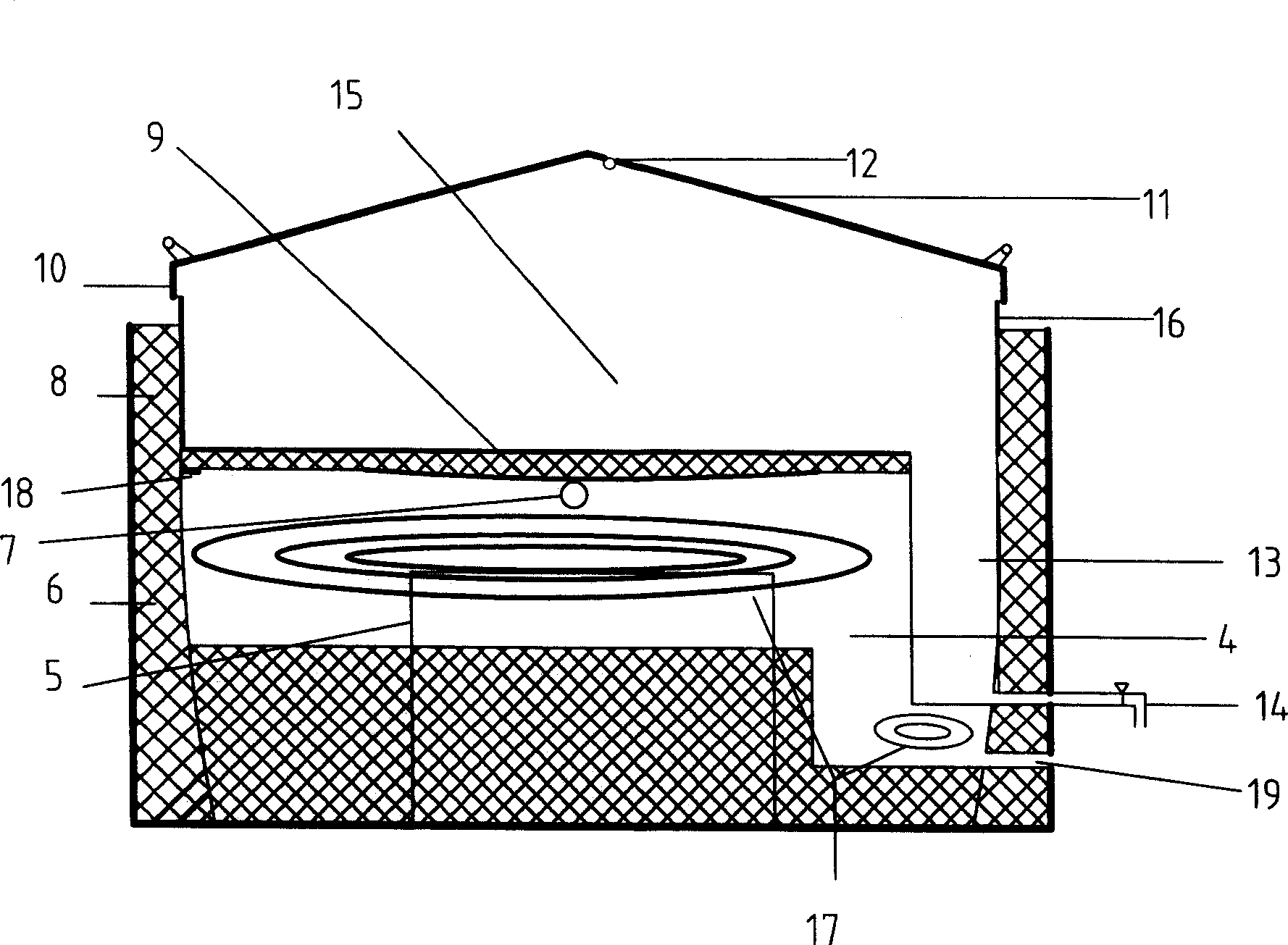

Method for processing steamed and baked bread and special-purpose equipment stove for steaming and baking

InactiveCN101461410AThe taste is mellow and strongRich dining tableBakery productsSpecial goods bakingEngineeringSponge cake

The invention relates to a method for processing food, especially for steaming and baking bun. The method comprises: making the leavened dough into steamed bread blanks, steamed stuffed bun blanks, dumpling blanks, steamed sponge cake blanks or pie blanks; and putting them into a special steaming-baking stove equipment to steam and bake by specific steps. The bun made in the invention has the crack layer of about 2 mm, is more soft and crisp than baked bun, and is more puffed, tender, aromatic and pliant than steamed bun; is salutary and safe, and protect the nutrition of the materials perfectly. The invention further provides an integrally designed special enclosed steaming-baking stove for processing the steamed-baked bun, which comprises oven chamber, heating device, steam griddle supporter, steam griddle heat preservation ring and steam griddle; achieves the advantages of , simple, practical and energy saving; can steam, bake and perform the steaming and baking synchronously, especially can guarantee the quality of the steamed-baked buns.

Owner:刘姝婧

Fish meat stuffing and food with the stuffing

Fish meat stuffing and food with the stuffing are provided. The fish meat stuffing is prepared from fresh-water fish meat, refined salt, lard oil, fish soup, celery, shiitake, ginger, welsh onion pricklyash peel oil and chicken essence through a conventional method. The food with the stuffing adopts the fish meat stuffing, and can be steamed stuffed buns, dumplings, wontons and pies. Through reasonable component matching, the fishy smell of the fresh-water fish meat is removed, nutrition composition of the fresh-water fish meat is fully utilized, and the reasonably matched fish meat stuffing and the food with the stuffing are provided. The fish meat stuffing is fresh, fragrant, good in taste and rich in nutrition and has functions of enhancing body constitution, boosting immunity, delaying senescence and the like after long-term eating.

Owner:田李奇

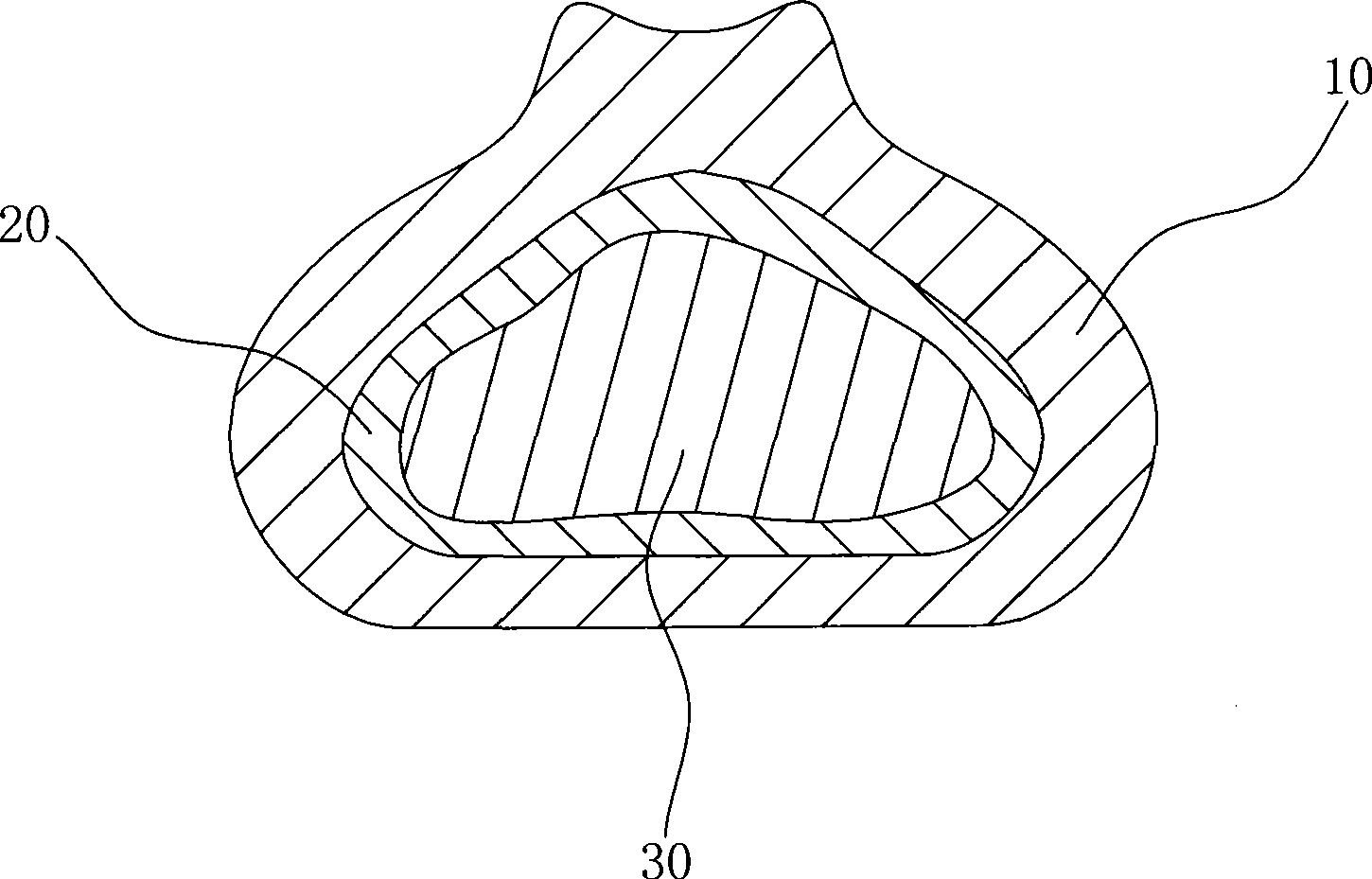

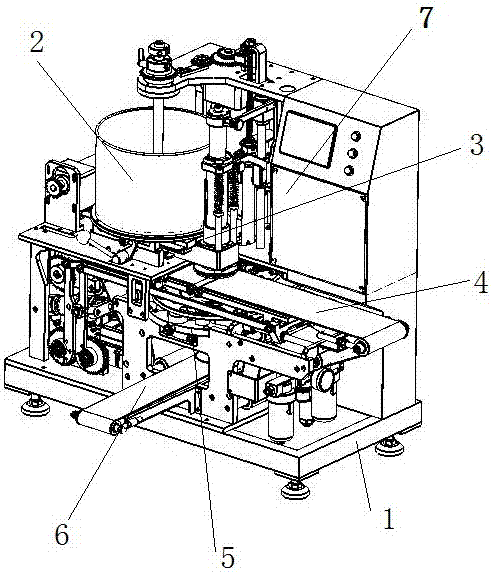

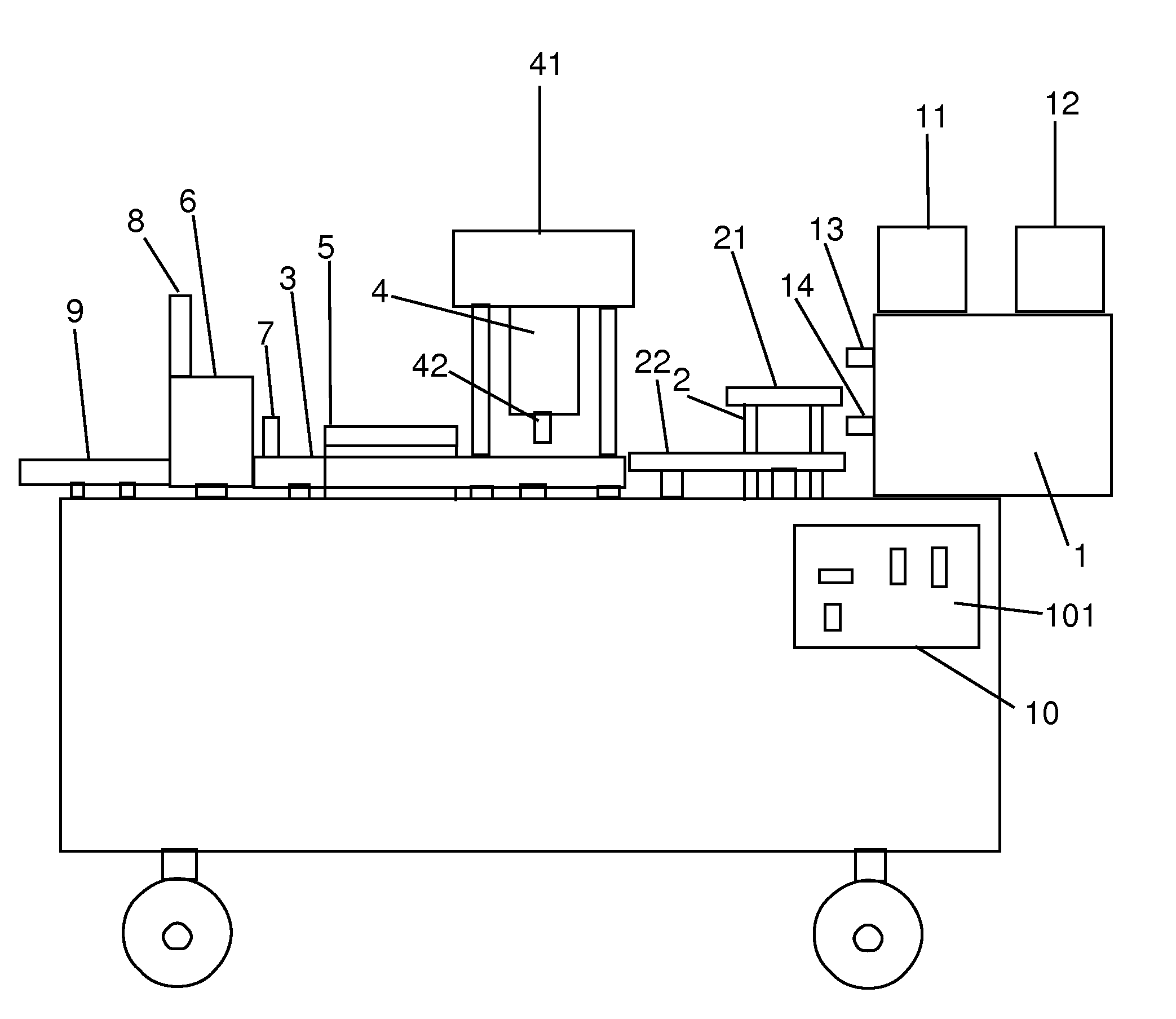

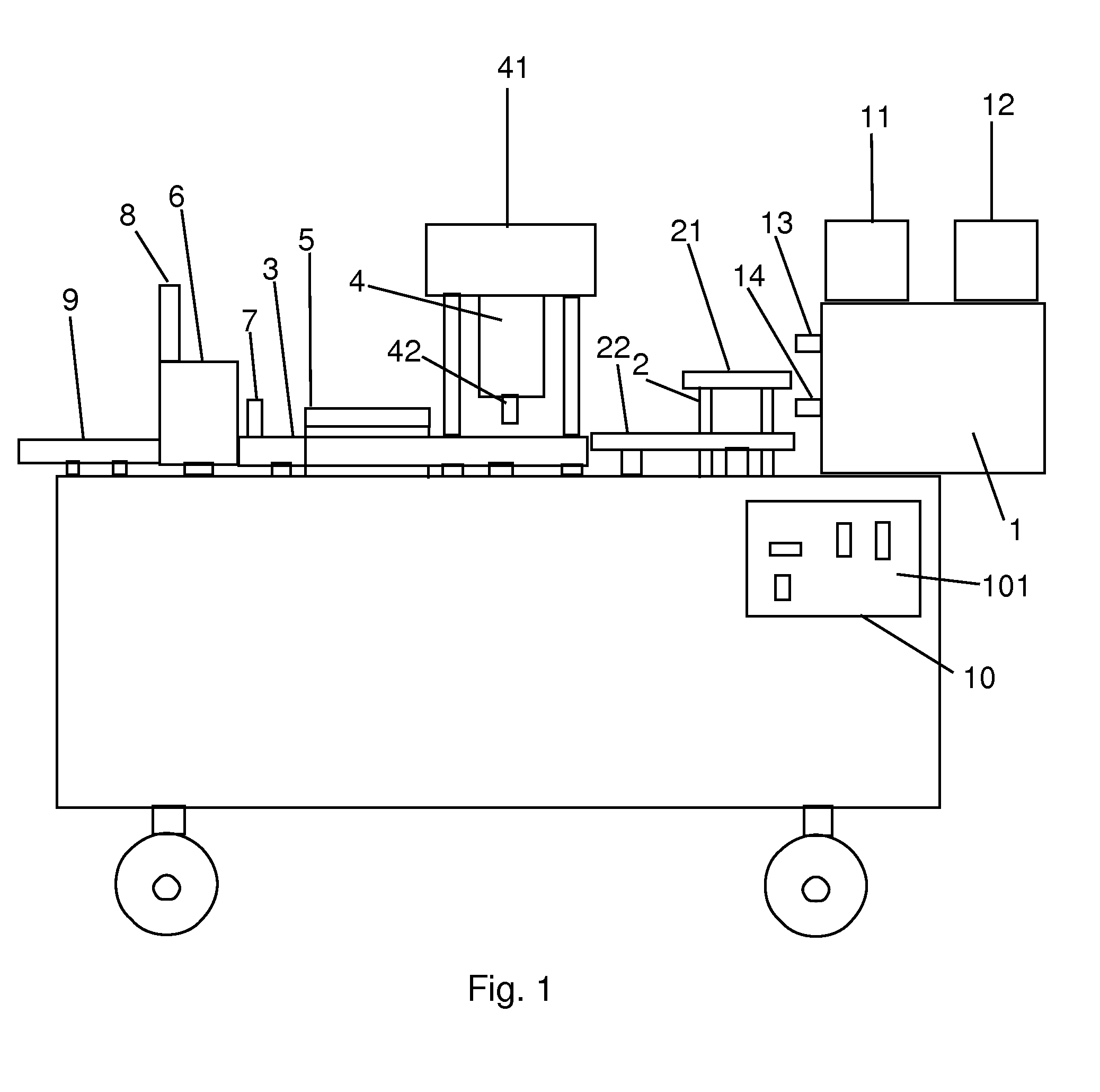

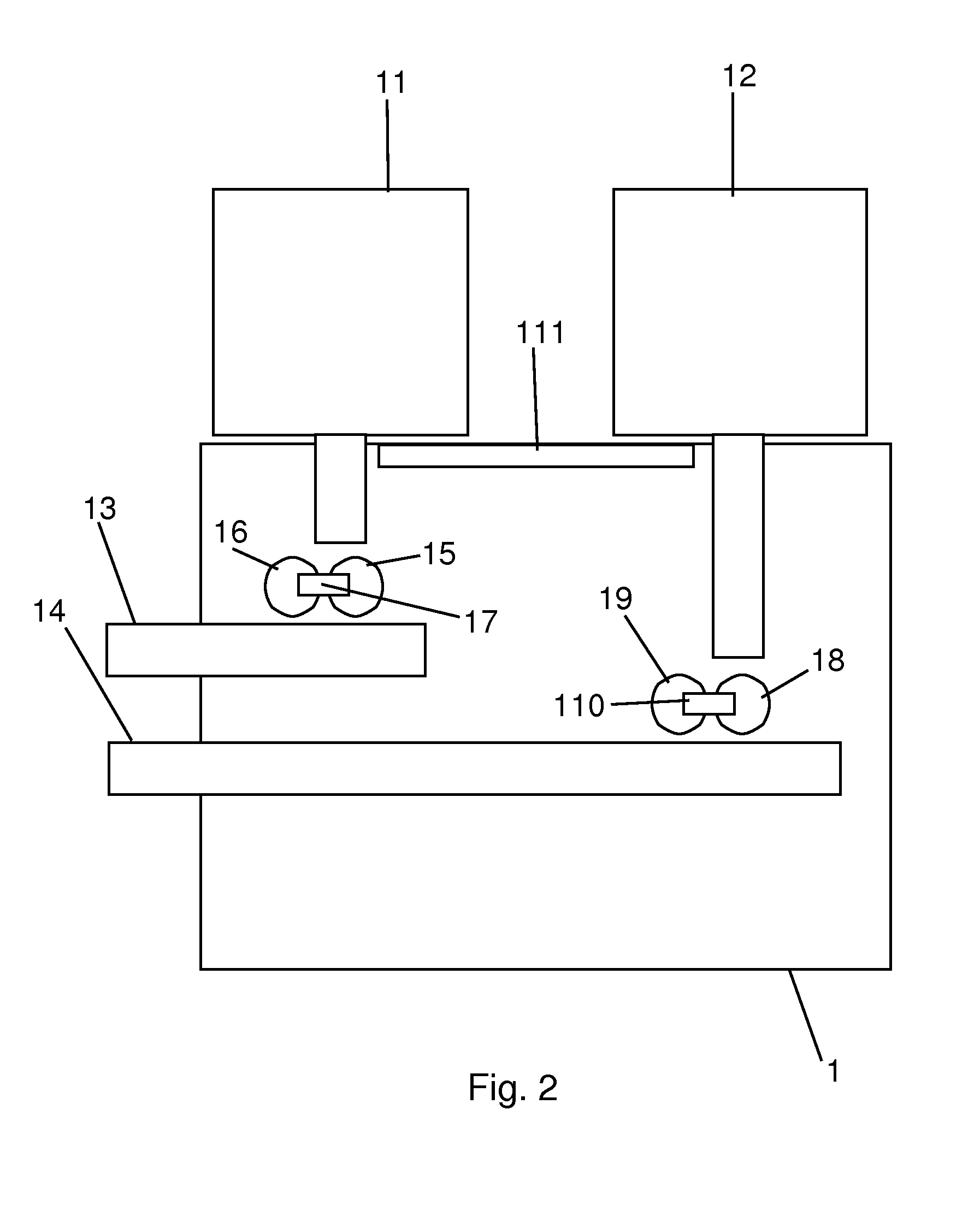

Bun machine

InactiveUS20160113291A1Easily brokenKeep longBaked article fillingDough-sheeters/rolling-machines/rolling-pinsEngineeringMechanical engineering

A bun machine includes: a pressing device for forming a first layer and a second layer; an overlaying device for forming a bun crust with the first layer and the second layer; a main transporter, wherein a first end of the main transporter is connected to the overlaying device for transporting the bun crust; a feeding device provided aside the main transporter, comprising: a filling tank for storing and inputting fillings into the feeding device; and a feeding unit feeding the fillings onto the bun crust; a wrapping device provided above the main transporter, wherein the wrapping device wraps the fillings with the bun crust for forming a filled roll; and a separating device connected to a second end of the main transporter, wherein the separating device squeezes the filled roll for separating and sealing the filled roll, so as to produce buns.

Owner:AURNISH ENTERPRISES

Flour rich in various buckwheat nutrients and preparation method thereof

The invention relates to flour rich in various buckwheat nutrients. The flour is prepared from the following raw materials in parts by weight: 100 parts of wheat flour and 5-25 parts of buckwheat outer seed coat flour, wherein the selected wheat flour is high-gluten wheat flour with dry basis protein content of greater than 12 percent, wet gluten content of greater than 32 percent and fineness of reaching 120 meshes. The buckwheat outer seed coat flour is prepared by the following method consisting of the steps of: shelling and enucleating carefully chosen buckwheat seeds; removing impurities of the obtained outer seed coat and then feeding the outer seed coat into a quick-freeze warehouse to freeze-dry until the water content is less than 6 percent; crushing by using an ultrafine grinder; and sieving with a 250-mesh sieve. According to the flour, the buckwheat outer seed coat flour is scientifically added into the wheat flour, so that the nutrition and health care value of the wheat flour is improved while the flavonoid material content, the dietary fiber content and the selenium content in the wheat flour are improved; and the flour can be used for preparing flour foods such as noodles, steamed breads, dumplings, cakes and steamed stuffed buns.

Owner:河南兴泰生物技术有限公司

Crispy fried stuffed bun, preparation method and pan dedicated therefor

InactiveCN1994095ASmall and exquisiteXuan soft and elasticBakery productsFood coatingFrying-pansFlavoring Agents

The invention relates to a method for producing fried bread, wherein said bread comprises skin and stuff. The stuff comprises 500g pork, 40-70g egg, 40-60g fecula, and 35-50g ginger, 70-85g flavoring agent, some green onion, and some water. The bottom of bread is thick with yellow skin. The invention also provides an aluminum pot, which can produce 300 breads at one time, with uniform temperature.

Owner:张友军

Bean jelly and cold rice noodle food fillings and manufacture method and application thereof

The invention relates to food fillings, in particular to bean jelly and cold rice noodle food fillings, which belong to the food field. Besides, the invention further discloses a manufacture method and application of the food fillings. The food fillings are bean jelly, or cold rice noodles, or the mixture of the bean jelly and the cold rice noodles, wherein the weight ratio of the bean jelly to the cold rice noodles is 1-1.5 to 1-1.5. The bean jelly and cold rice noodle food fillings can be widely applied to the production of foods including Shao-Mai, spring rolls, fried dumplings, steamed dumplings, steamed stuffed buns, dumplings, sweet dumplings, Chinese dumpling soup and the like. In addition, the bean jelly and cold rice noodle food fillings can be further suitable for the production of quick-frozen foods such as quick-frozen dumplings and quick-frozen steamed stuffed buns, and can be stored for a long time without nutrition loss.

Owner:杨明德

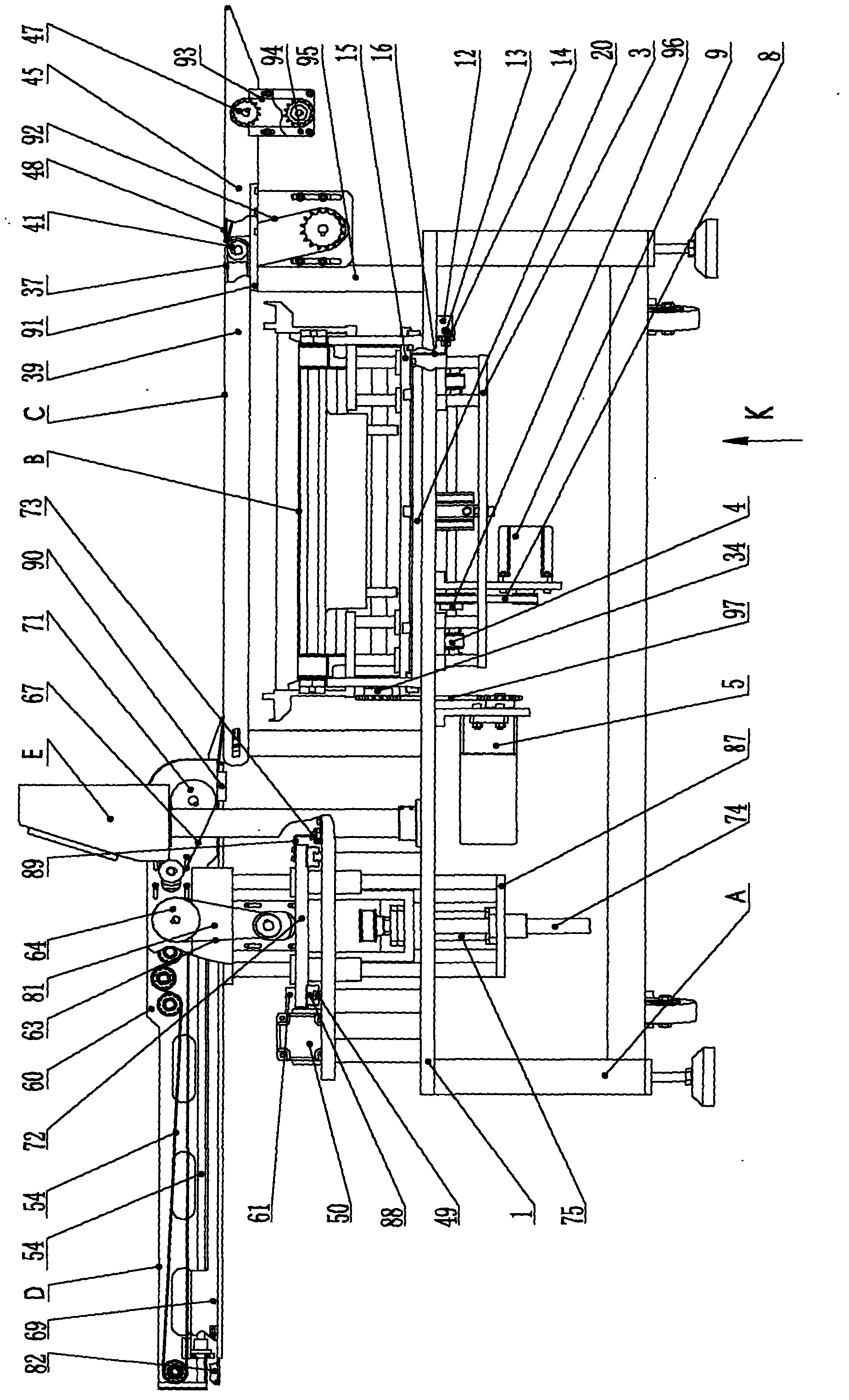

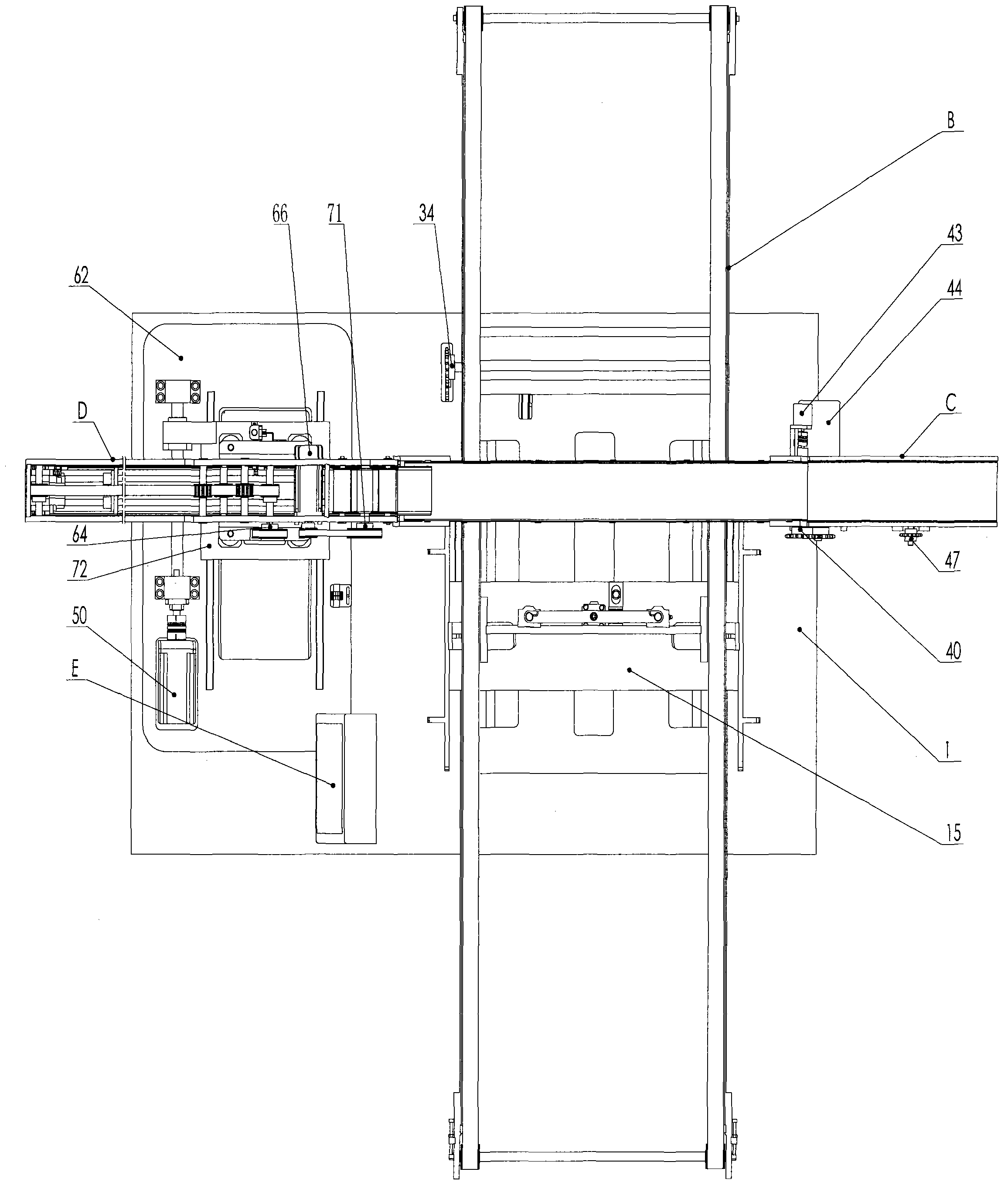

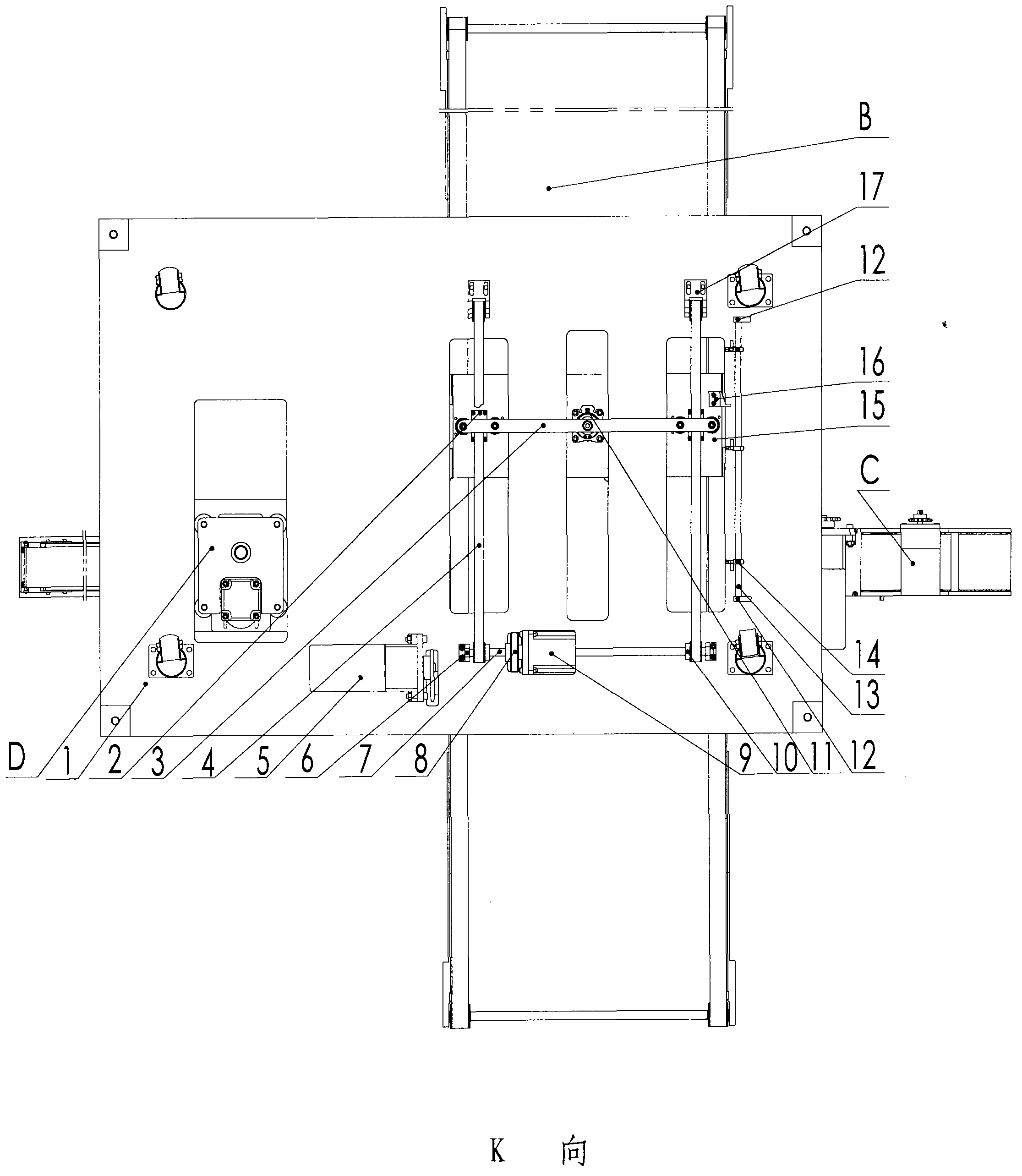

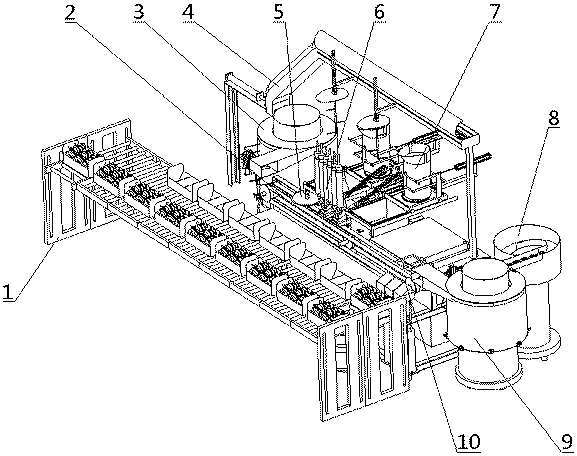

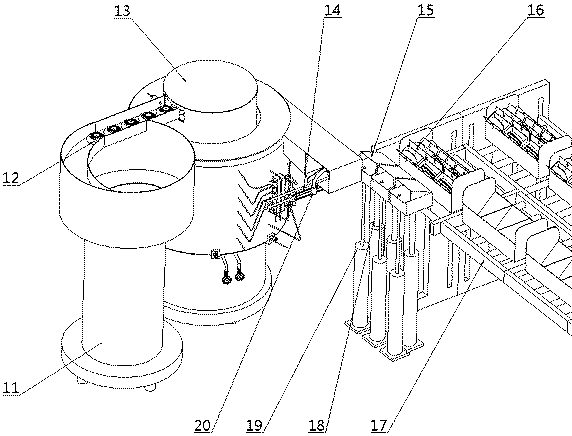

Automatic tray placing machine

ActiveCN103250746AReduce labor intensityEnsure hygiene and safetyDough processingEngineeringMechanical engineering

The invention discloses an automatic tray placing machine which is used for placing formed steamed buns and steamed stuffed buns into a tray. The automatic tray placing machine comprises a stand; and a large bottom plate of the stand is provided with a longitudinal conveying mechanism, a horizontal conveying mechanism, a material moving mechanism and a control system. The automatic tray placing machine can be matched with a steamed bun preparing machine and a steamed stuffed bun preparing machine for use, and the made steamed buns and steamed stuffed buns can be automatically placed into the tray, so that the labor intensity of an operator is greatly lightened, the production efficiency is improved, the automatic production is realized, and the food hygiene safety is guaranteed.

Owner:HENAN WANJIE INTELLIGENT TECH

Quick-frozen steamed bread with vegetable stuffing and preparation method thereof

InactiveCN101731519AEnhance product quality standardizationImprove securityDough treatmentPre-baking dough treatmentPotato starchGlutaminase

The invention relates to quick-frozen steamed bread with vegetable stuffing and a preparation method thereof, belonging to the food processing technical field. The preparation method comprises the following steps: firstly placing flour, Yanshan yeast, aluminum-free baking power, white granulated sugar, shortening, salt, transglutaminase, lipase, xylanase, glucose oxidase, trehalose, ascorbic acid, lecithin, sucrose ester, glycerin, locust bean gum, artemisia glue, carboxymethyl cellulose, guar gum, wheat gluten and wheat starch or corn starch or potato starch or rice starch in a mixing tank, stirring evenly in slow speed, then adding water to stir in medium speed and form a dough; pressing the dough to form, performing pre-fermentation, cooling, quick-freezing (or directly freezing), performing frozen storage for standby; and when in need, directly steaming to obtain the fresh steamed bread product, wherein the dough which is not treated by pre-fermentation is needed to be fermented firstly and secondly steamed. The application of the invention lays the foundation for the industrialized production of the steamed bread (steamed bun) with vegetable stuffing, increases the quality standardization, safety and convenience of the product, and avoids flavor loss caused by repeated boiling.

Owner:JIANGNAN UNIV

Bamboo charcoal steamed stuffed bun and making method thereof

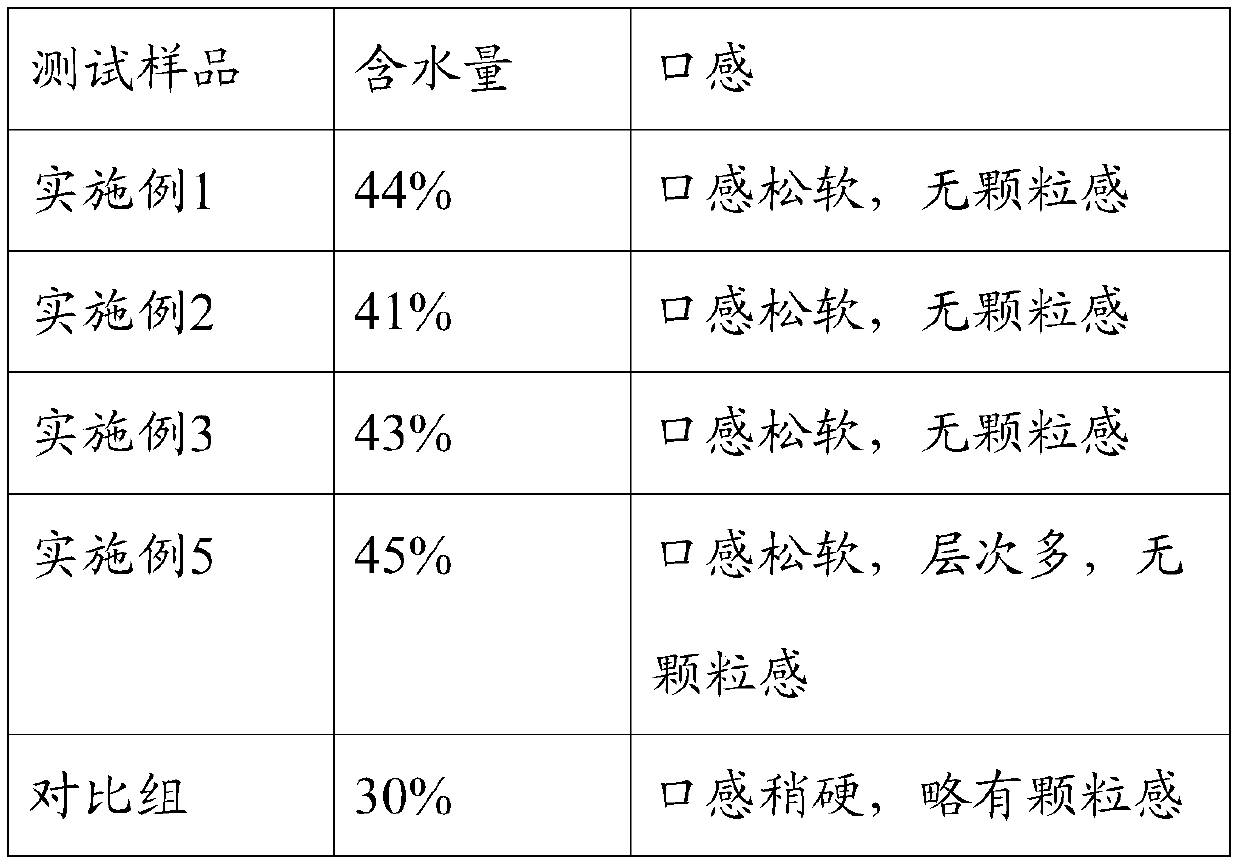

InactiveCN105495325ARich tasteRich layersSugar food ingredientsYeast food ingredientsCooking & bakingBiological activation

The invention provides a bamboo charcoal steamed stuffed bun. The bamboo charcoal steamed stuffed bun comprises a wrapper, wherein the wrapper is made of black dough; the black dough is prepared from the following raw materials in parts by weight: flour, white sugar, salt, fresh yeast, yeast, baking powder, milk powder, water and edible bamboo charcoal powder; the wrapper can also be made of the black dough and white dough. The invention further provides a making method of the bamboo charcoal steamed stuffed bun. The making method comprises the steps of powder mixing, yeast-water mixing, mixing into dough, dough pressing, strict control of time and temperature, fermentation, and baking-steaming. In a formula, natural bamboo charcoal powder is added, so that the effects of detoxifying and beautifying are achieved; moreover, water content in the formula is up to a half of the total amount of all the components, so that the made steamed stuffed bun has high water content and dense mouthfeel. All the powdery materials are mixed with the salt in order to ensure that the salt can be fully dispersed into the powder. The yeast is fully dissolved into the water, so that full activation of the yeast is facilitated; meanwhile, the white sugar is taken as a carbon source for yeast fermentation, so that the growth of saccharomycetes can be facilitated.

Owner:么居桦

Thin-skinned steamed stuffed bun and production method thereof

InactiveCN105918820ABright and brightOrnamentalCheese manufactureFood shapingBiotechnologyFree range

The invention provides a thin-skinned steamed stuffed bun and a production method thereof. The thin-skinned steamed stuffed bun comprises the following raw materials: flour, dioscorea roots, pork of free-ranging pigs, fresh vegetables, eggs, bean curd with fermented slurry, alum-free vermicelli, salt, powdered pepper, Chinese prickly ashes, minced scallions and gingers, and sesame oil; the method for producing the thin-skinned steamed stuffed bun comprises the following four steps: preparation of the dough and skin, preparation of stuffing, a production process, and a cooking process. High-quality wheat is carefully chosen and grinded into flour, unique viscose juice in the dioscorea roots with long hairs is used for kneading dough, the dough skin is thin and like a cicada's wing, and the dough is chewy and elastic with chewy taste; steamed stuffed bun prepared by the dough skin is white and shiny, and has paper liked skins, tender pork, abundant oil, large stuffing, and big size; stuffing inside can be seen indistinctly from the dough skin, white stuffing contains bean curd, green stuffing contains leek, red stuffing contains radishes, black stuffing contains edible fungus, yellow stuffing contains eggs, steamed stuffed bun is bright and beautiful with ornamental values, so the steamed stuffed bun is called thin-skinned steamed stuffed bun.

Owner:孙怀兵

Method for refreshing soybean milk film steamed stuffed buns at room temperature

InactiveCN101919570AGuaranteed tasteExtended shelf lifeFood preservationFood preparationProcess engineeringMouthfeel

The invention discloses a method for refreshing soybean milk film steamed stuffed buns at room temperature, comprising the following steps: (1) purchasing raw materials; (2) detecting the raw materials; (3) putting the raw materials into a storage; (4) taking the raw materials; (5) processing the raw materials; (6) dosing; (7) stirring; (8) manufacturing and molding; (9) panning and typing; (10) stewing the materials until the materials are ripe; (11) packing; (12) sterilizing; (13) aging the storage; and (14) putting finished products into the storage. By applying the raw material sterilization technology, the production process bacteriostatic technology, the vacuum packing and high-temperature high-pressure linear control sterilization technology and the like to refresh the soybean milk film steamed stuffed buns at room temperature, and on the basis of maintaining the taste of the soybean milk film steamed stuffed buns and not increasing the cost, the invention prolongs the quality guarantee period ( reaching 180 days at room temperature) of the soybean milk film steamed stuffed buns at room temperature, thereby ensuring that consumers can buy the soybean milk film steamed stuffed buns across the country at any time and tastes the real taste of famous Chinese snacks.

Owner:HUZHOU DINGLIANFANG FOOD

De-alcoholic fish stuffed bun and making method thereof

InactiveCN102630976AReasonable collocationUnique stuffing recipeFood preparationBiotechnologyMonosodium glutamate

The invention discloses a de-alcoholic fish stuffed bun and a making method thereof. The de-alcoholic fish stuffed bun is mainly made of materials according to parts by weight by mixing, and the materials include flour, mandarin fish, streaky pork, pigskin jelly, agaric, shiitake, celery, chopped green onion, bruised ginger, white sugar, yellow rice wine, sweet potato starch, sesame oil, spiced vinegar, soy sauce, refined salt, pepper powder and monosodium glutamate. A stuffing formula for the de-alcoholic fish stuffed bun is unique, the mandarin fish tastes tender and delicious, the stuffing with the mandarin fish tastes unique, protein, fat, vitamins and cellulose are reasonably allocated, and accordingly the de-alcoholic fish stuffed bun is nutrient, and is a good health food suitable for young and old. Adding silybum marianum, plantain, green tea and lotus leaf juice in bun making and dough mixing makes the de-alcoholic fish stuffed bun health-care, de-alcoholic and liver-protective.

Owner:池州市昭明诗港酒店 +1

Coarse food grain gaojin flour

It utilizes various coarse food grains or mixed grains, and separately grinds them into fine flours with above 80 meshes, then adds strong-increasing agent and corn starch and adopts a certain preparation process so as to obtain the invented coarse grain high-strong flour, including corn high-strong flour, sorghum high-strong flour, millet high-strong flour, buckwheat high-strong flour and mixed flour high-strong flour. These high-strong flours like wheat flour can be made into various flour foods and various cakes.

Owner:李京杭

Wild boar health baozi with pine nut

InactiveCN107198106ADelicious meatStrong gameFood coatingFood ingredient functionsMonosodium glutamateAnimal science

The invention discloses wild boar health baozi with pine nut, characterized in that stuffing is made from, by weight, 400 parts of wild boar, 100 parts of pine nut, 100 parts wild boar skin jelly, 10 parts of longan, 10 parts of dried shiitake mushroom, 7 parts of ginseng root, 6 parts of notoginseng root, 5 parts of black sesame seed, 2 parts of tall gastrodia rhizome, 2 parts of fritillary bulb, 2 parts of dried ginger, 2 parts of water chestnut, 2 parts of lotus seed,1 part of anise, 1 part of fennel, 1 part of monosodium glutamate, 1 part of spices, 1 part of white sugar, suitable edible oil, suitable cooking wine and suitable soy sauce; skin is made from, by weight, 500 parts of wheat flour, 100 parts of purple sweet potato flour, 5 parts of yeast, and suitable water. The invention also discloses a method of making the wild boar health baozi with pine nut.

Owner:朱浩其

Steamed bun steaming, baking and automatic-vending system

PendingCN107240191ACoin-freed apparatus detailsApparatus for dispensing discrete articlesProcess engineeringBiology

The invention relates to a steamed bun steaming, baking and automatic-vending system. The system is formed by expanding a Chinese hamburger automatic-vending system, and the Chinese hamburger automatic-vending system comprises an automatic flat-cake feeding device, an automatic flat-cake steaming and baking device, a pinned automatic conveying device, an automatic flat-cake cutting device, a sauce injection and meat-block filling device, a meat-block heating automatically-adding and heat-insulation conveyor stove, an automatic Chinese hamburger packaging device and a roller-type automatic conveyor. The steamed bun steaming, baking and automatic-vending system is located at the right side of the Chinese hamburger automatic-vending system and comprises a steamed bun vibration conveying device, a steamed bun steaming and baking device and an automatic steamed bun packaging device, and the automatic steamed bun packaging device and the automatic Chinese hamburger packaging device are installed in a parallel mode. The automatic Chinese hamburger packaging device is located at the tail end of the pinned automatic conveying device, and the roller-type automatic conveyor is located at the front of the automatic Chinese hamburger packaging device. By fully utilizing an existing Chinese hamburger automatic-vending system platform, the steamed bun steaming, baking and automatic-vending system expands the functions of steamed bun food vibration-conveying, steaming and baking, and achieves double purposes. The steamed bun steaming, baking and automatic-vending system belongs to the field of food processing.

Owner:王建忠

Steamed hepatoprotective fish meat bun and preparation method thereof

InactiveCN102640943AUnique stuffing recipeReasonable collocationFood preparationBiotechnologyMonosodium glutamate

The invention discloses a steamed hepatoprotective fish meat bun and a preparation method thereof. The steamed hepatoprotective fish meat bun is mainly prepared by mixing the following raw materials according to a certain weight part.: flour, mandarin fish, streaky pork, pigskin frozen, edible fungus, mushrooms, celery, green onion, ginger, white sugar, rice wine, yam starch, sesame oil, balsamic vinegar, soy sauce, salt, pepper and monosodium glutamate The steamed hepatoprotective fish meat bun has a unique stuffing recipe, mandarin fish meat is tender and delicious, the stuffing tastes different because of the addition of the mandarin fish meat, protein, fat, vitamins and cellulose are balanced, and the nutrition is rich, so the bun is a good health food, which is suitable for being eaten by everyone. When the flour is mixed, milk thistle, plantain, green tea and lotus leaf juice are added to play a health-care role to protect the liver.

Owner:池州市昭明诗港酒店 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com