Bamboo charcoal steamed stuffed bun and making method thereof

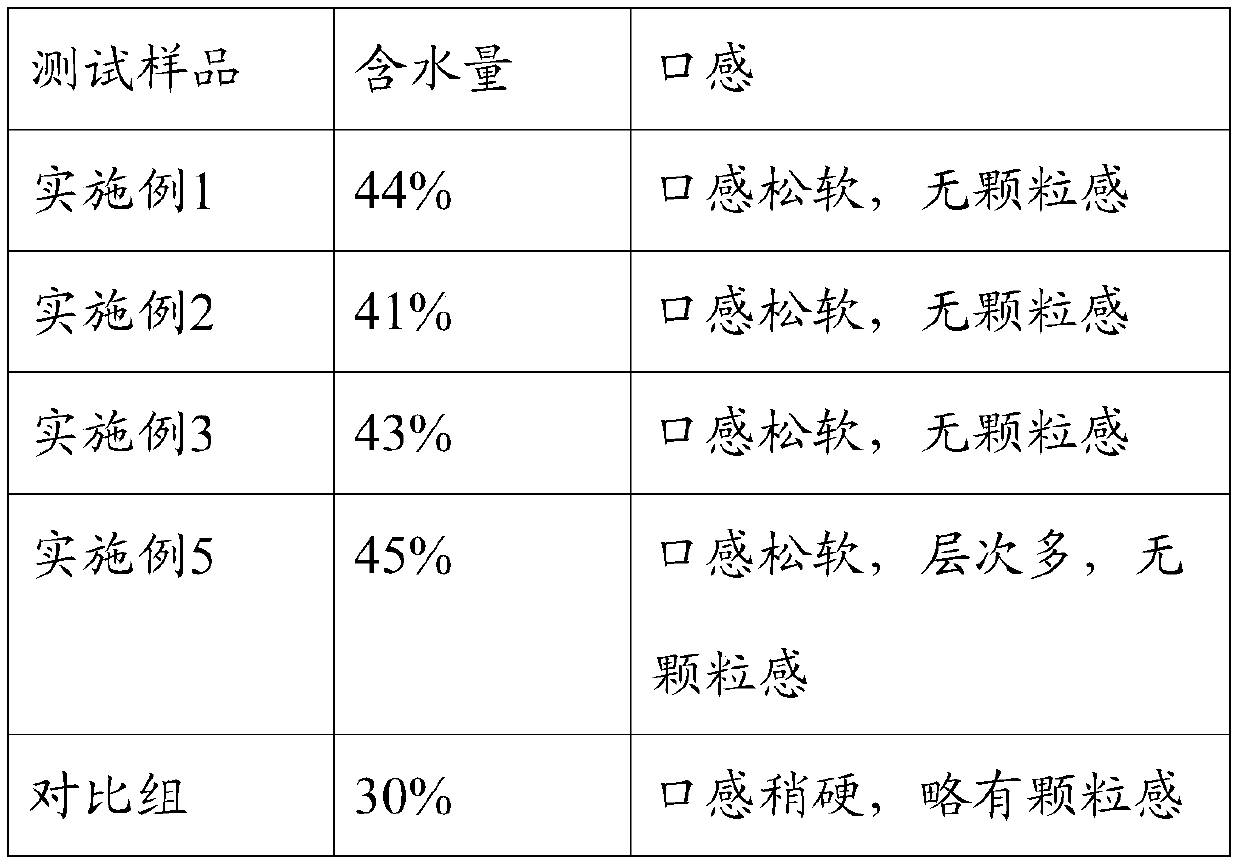

A production method and technology of steamed buns, which are applied in the food field, can solve the problems of low water content and hard taste of bread, and achieve the effect of multiple layers, increased recognition and rich taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A bamboo charcoal steamed stuffed bun comprises dough sheets, the dough sheets are made of black dough, and the black dough includes the following raw materials in parts by weight:

[0041] 500 parts of flour; 10 parts of sugar; 5 parts of salt; 3 parts of fresh yeast; 6 parts of yeast; 7 parts of baking powder; 10 parts of milk powder; 260 parts of water; 2 parts of edible bamboo charcoal powder.

[0042] The above-mentioned raw materials are prepared according to the following method:

[0043] Step S100, grinding the bamboo charcoal powder so that the particle size is 1000-1500 mesh.

[0044] Step S101, mixing flour, baking powder, bamboo charcoal powder, salt and milk powder, stirring at a low speed.

[0045] Step S102, mixing fresh yeast, yeast, sugar and water until the fresh yeast, yeast, and sugar are dissolved.

[0046] Step S103, pour the mixture obtained in step S102 into the mixture obtained in step S101, stir at low speed for 2-3 minutes, and stir at mediu...

Embodiment 2

[0051] A bamboo charcoal steamed stuffed bun comprises dough sheets, the dough sheets are made of black dough, and the black dough includes the following raw materials in parts by weight:

[0052] 550 parts of flour; 20 parts of sugar; 8 parts of salt; 3 parts of fresh yeast; 8 parts of yeast; 9 parts of baking powder; 12 parts of milk powder; 280 parts of water; 3 parts of edible bamboo charcoal powder. The preparation method of this embodiment is the same as that of Embodiment 1.

Embodiment 3

[0054] A bamboo charcoal steamed stuffed bun comprises dough sheets, the dough sheets are made of black dough, and the black dough includes the following raw materials in parts by weight:

[0055] 450 parts of flour; 10 parts of sugar; 3 parts of salt; 3 parts of fresh yeast; 5 parts of yeast; 5 parts of baking powder; 8 parts of milk powder; 240 parts of water; 1 part of edible bamboo charcoal powder. The preparation method of this embodiment is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com