Frozen raw steamed stuffed bun blanks and preparation technology thereof

A steamed stuffed bun and raw body technology, which is applied in the field of frozen raw steamed buns and its production process, can solve the problems of high requirements for production, distribution, and storage equipment, cracking, skin blistering, etc., and achieve shortened proofing time, sufficient elasticity, and sticky texture. Good elasticity and retractability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

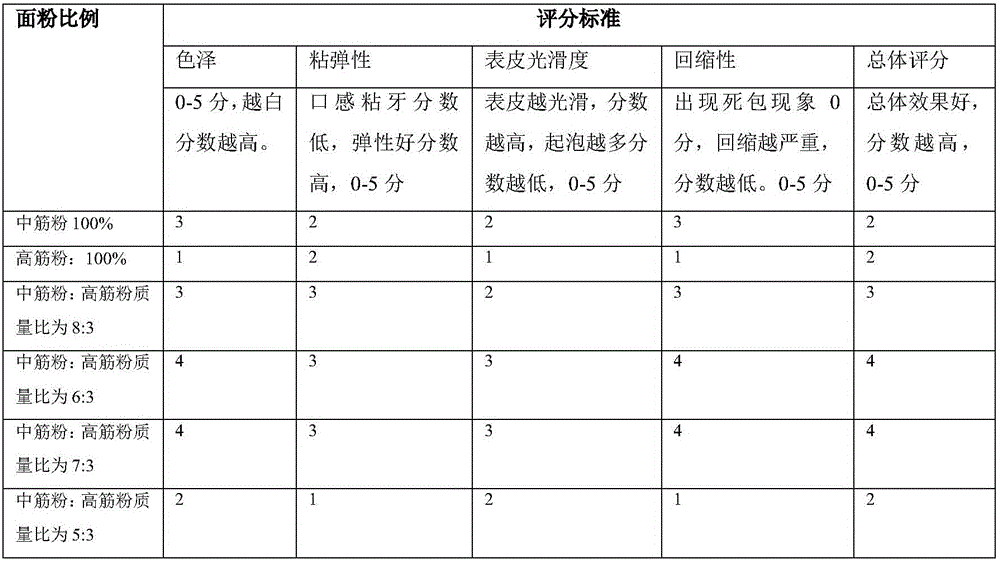

Embodiment 1

[0037] A frozen raw steamed stuffed bun, said steamed stuffed bun comprises the following components by weight: flour 450, old noodles 600, semi-dry yeast 1, salt 1, sugar 12, water 200.

[0038] The temperature of the water is 10° C., and the mass ratio of medium-gluten flour and low-gluten flour in the flour is 8:3.

Embodiment 2

[0040] A frozen raw body steamed stuffed bun, the steamed stuffed bun comprises the following components by weight: 600 flour, 850 old noodles, 5 semi-dry yeast, 4 salt, 18 white sugar, and 300 water.

[0041] The temperature of the water is 12° C., and the mass ratio of medium-gluten flour and low-gluten flour in the flour is 6:3.

Embodiment 3

[0043] A frozen raw steamed stuffed bun, said steamed stuffed bun comprises the following components by weight: 500 flour, 750 old flour, 4 semi-dry yeast, 3 salt, 16 white sugar, and 250 water.

[0044] The temperature of the water is 11° C., and the mass ratio of medium-gluten flour and low-gluten flour in the flour is 7:3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com