Side formwork placement method for PC (Personal Computer) numerical control production line

A production line and side mold technology, applied in the field of side mold placement of PC numerical control production line, can solve the problems of inability to adjust, easy leakage of concrete liquid, poor sealing of ends and bottoms, etc., so as to reduce waste of resources and reduce investment costs. , to achieve the effect of generality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

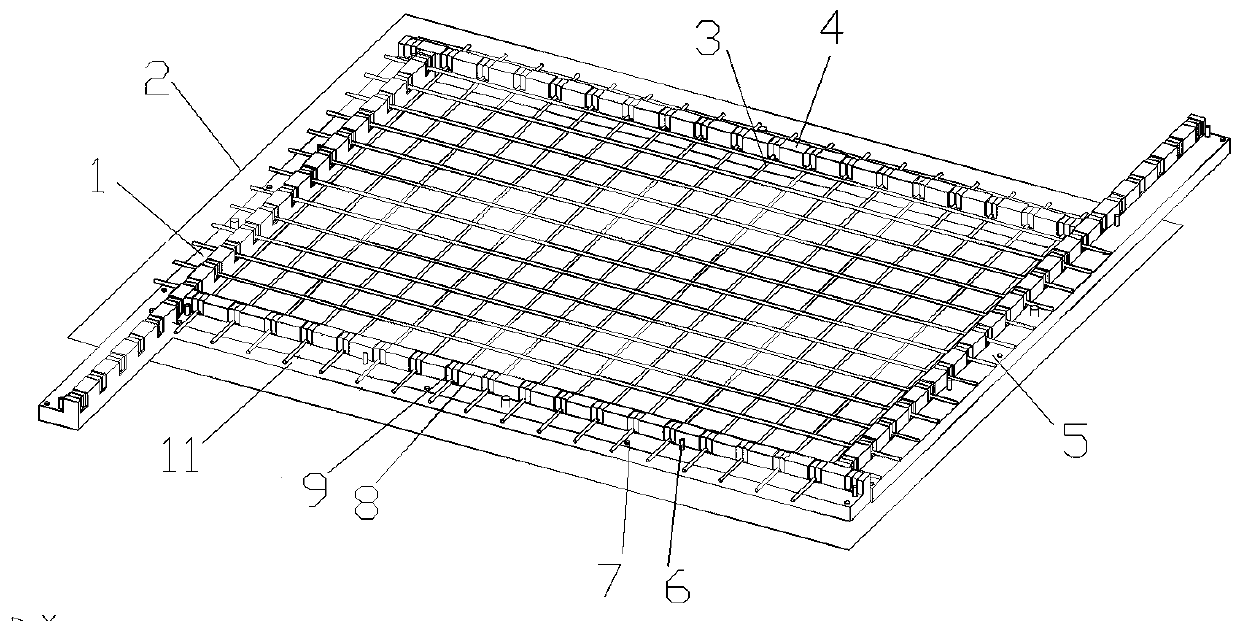

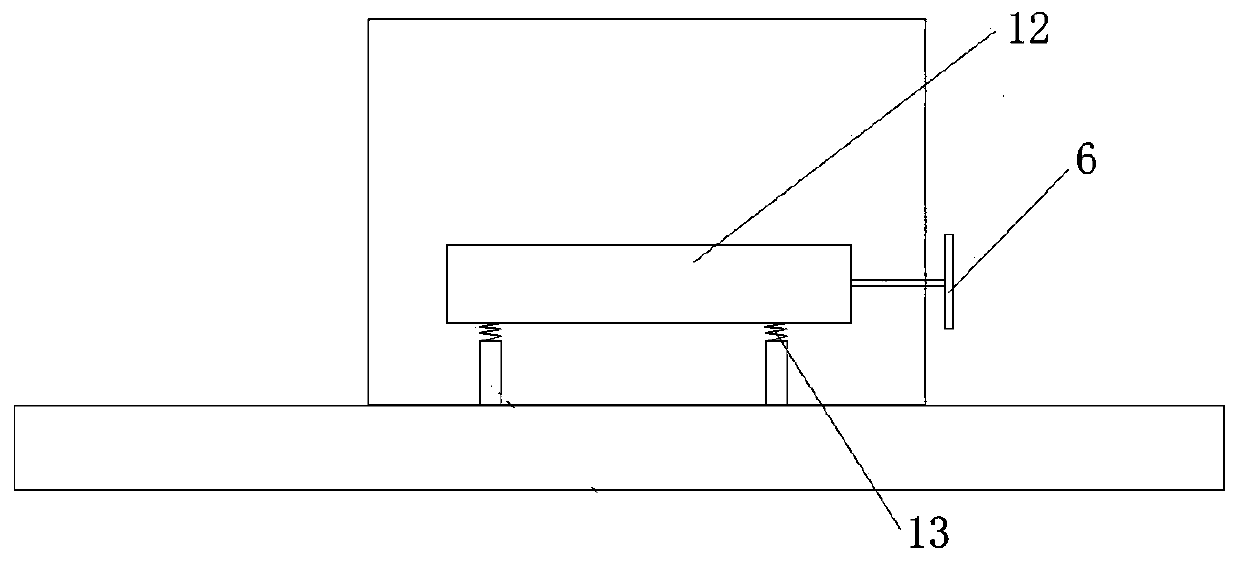

[0017] See attached figure 1 and figure 2 It is an embodiment of the present invention.

[0018] A method for placing side molds for a PC numerical control production line, which is realized through the following steps: 1) Making side molds: respectively making a first side mold 11, a second side mold 5, a third side mold 4, and a fourth side mold 1 , each side mold includes a base body and a plurality of fixed blocks 8 located on the surface of the base body, each fixed block 8 is provided with an inflatable bag 9 at both ends, the inside of the base body is provided with an inflation pipe, and the surface is provided with the Inflatable joints 7 connected by inflatable pipelines, the inflatable pipelines are also connected to each inflatable bag 9 respectively; a plurality of powerful magnet devices are also provided inside the base body, and the powerful magnet devices include powerful magnets 12 and are connected with the powerful magnets. 12 connected magnetic switches...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com