Corrosion resisting method for tubing-casing annulus in well gas well completion with packer

An oil-casing annulus and packer technology is applied in the field of pipeline anti-corrosion, which can solve the problems of high operating cost, large amount of corrosion inhibitor, and inappropriate anti-corrosion treatment, and achieves reduction of corrosion rate, low cost, and convenient scale. The effect of promoting the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

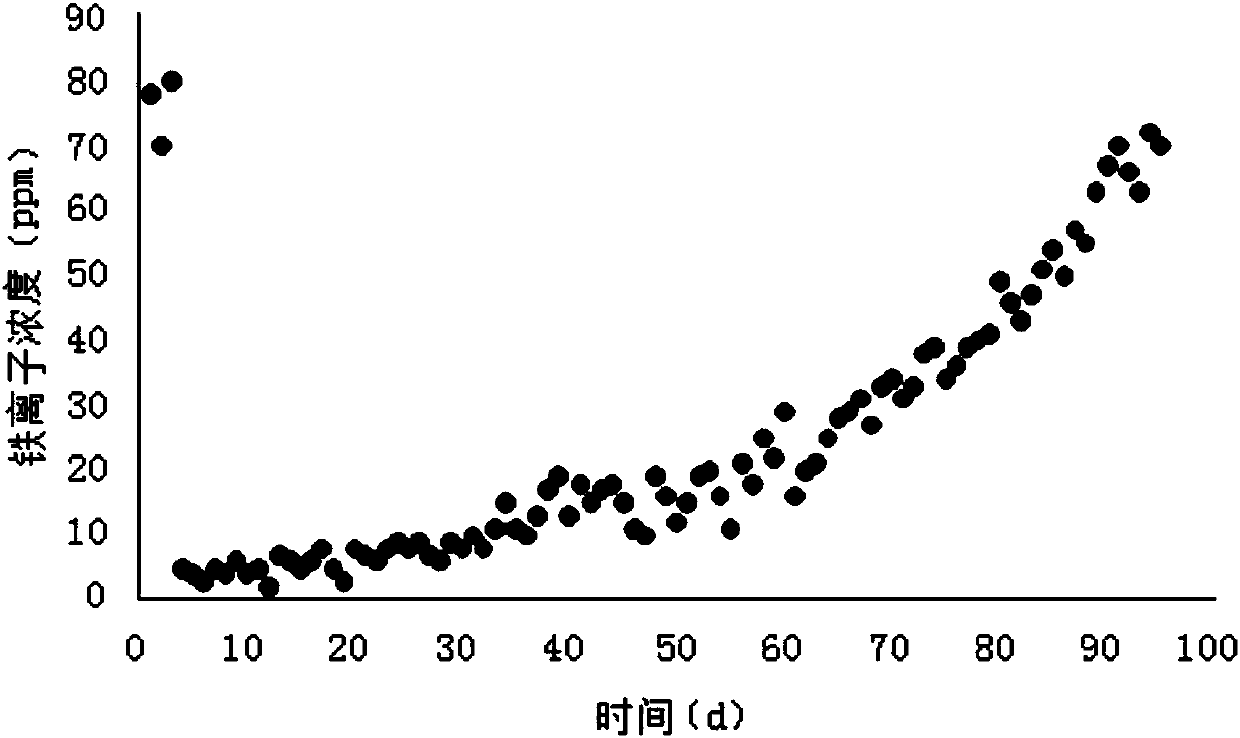

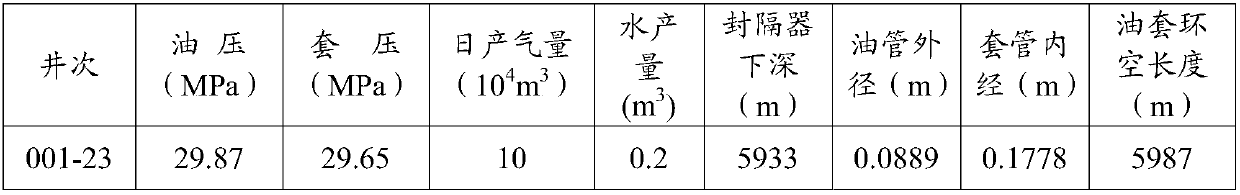

[0047] This embodiment provides an anti-corrosion method for the annulus of the oil casing of the packer well completion gas well, and the anti-corrosion treatment is performed on the Longgang 001-23 well by this method. Well Longgang 001-23 was completed with a packer. After production started, the casing pressure gradually increased from 0 to finally higher than the oil pressure, indicating that there was leakage in the oil casing annulus, and anticorrosion treatment for the oil casing annulus was required. The specific production status of Well Longgang 001-23 is shown in Table 1:

[0048] Table 1 Production data of Well Longgang 001-23

[0049]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com