A kind of anti-corrosion magnetic nano material with sustained release effect and preparation method thereof

A magnetic nanometer technology, applied in the preparation of microspheres, microcapsule preparations, etc., can solve the problems of complex preparation method and single function, and achieve the effect of simple and controllable method, widening application scope and easy promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

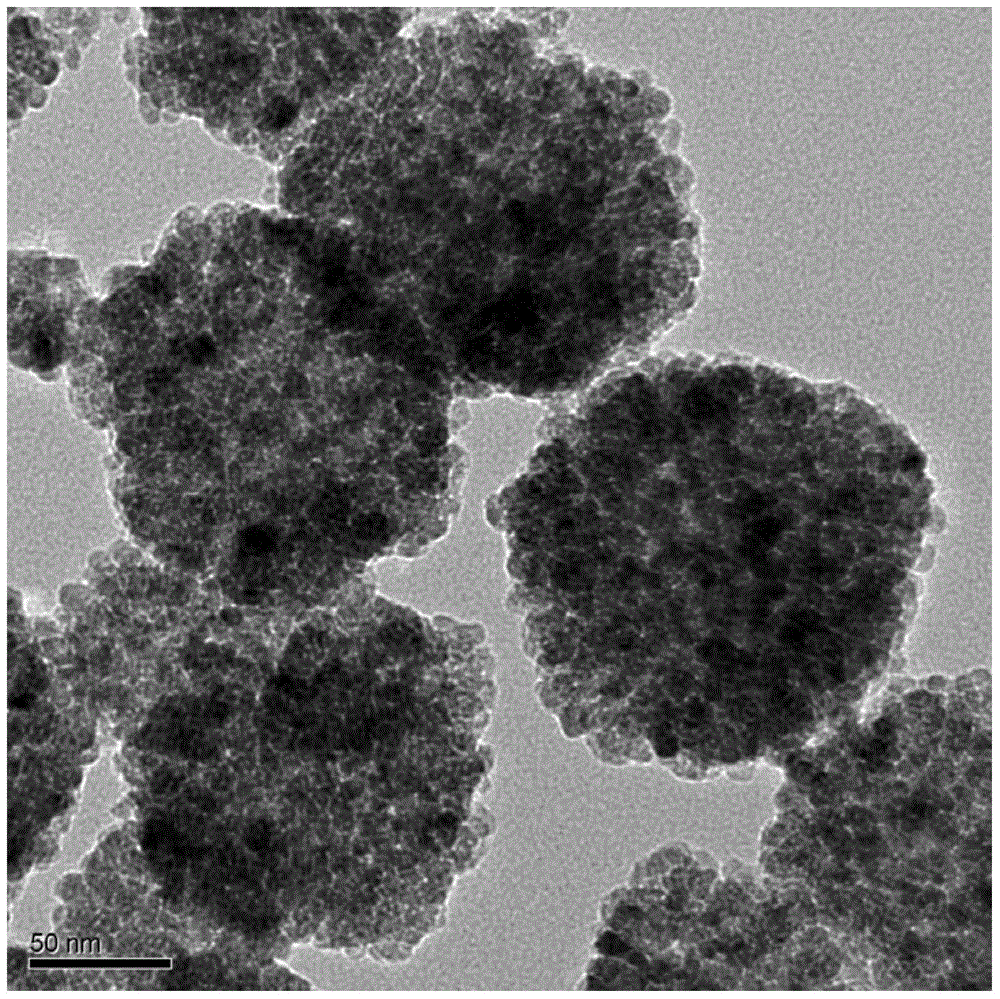

[0033] FeCl 3 ·6H 2 O(2mmol), CoCl 2 ·6H 2 Add O (1mmol) and sodium acetate (26mmol) into a mixed solvent of 10mL ethylene glycol and 20mL diethylene glycol, stir in a water bath at 40°C for 1.5h, and transfer the obtained solution into a hydrothermal reaction kettle after fully dissolving , the temperature was raised to 200°C, and after 3 hours of reaction, it was cooled to room temperature. Magnetic separation, pouring off the waste liquid, washing with absolute ethanol and deionized water, until the magnetic suction clear liquid is colorless, and drying to obtain CoFe with a particle size of about 20-100nm 2 o 4 magnetic nanospheres. It is characterized by XRD: the positions of the main diffraction peaks are all the same as those of CoFe2 o 4 Corresponding to the standard spectrum, it is CoFe 2 o 4 magnetic nanospheres.

[0034] 0.1g CoFe 2 o 4 Magnetic nanospheres were mixed with 20 mL of branched polyethyleneimine (PEI) aqueous solution with a molecular weight ...

Embodiment 2

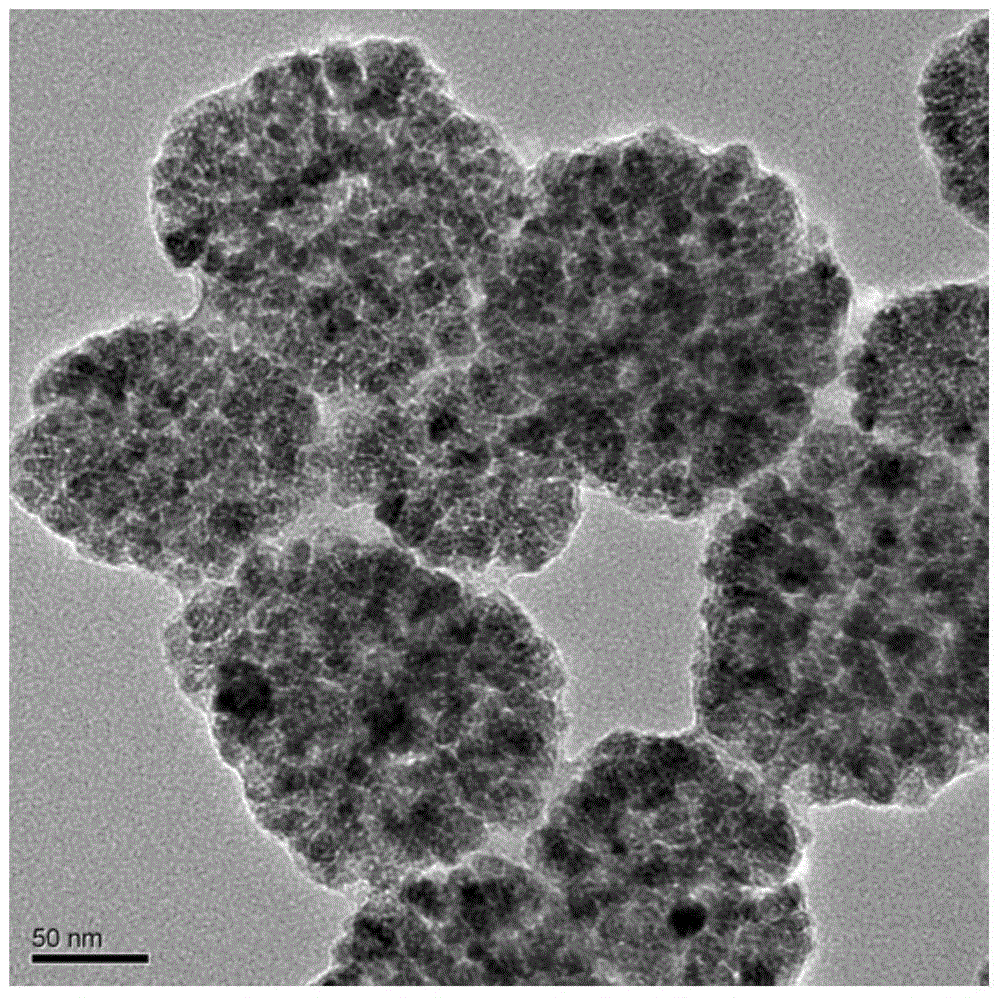

[0040] FeCl 3 ·6H 2 O(2mmol), CoCl 2 ·6H 2 Add O (1mmol) and sodium acetate (40mmol) into a mixed solvent of 15mL ethylene glycol and 30mL diethylene glycol, stir in a water bath at 50°C for 1h, and transfer the obtained solution into a hydrothermal reaction kettle after fully dissolving , the temperature was raised to 220°C, and after 5 hours of reaction, it was cooled to room temperature. Magnetic separation, pouring off the waste liquid, washing with absolute ethanol and deionized water, until the magnetic suction clear liquid is colorless, and drying to obtain CoFe with a particle size of about 200nm 2 o 4 magnetic nanospheres. It is characterized by XRD, the results are shown in Image 6 , the result surface: the positions of the main diffraction peaks are the same as those of CoFe 2 o 4 Corresponding to the standard spectrum, it is CoFe 2 o 4 magnetic nanospheres.

[0041] 0.1g CoFe 2 o 4 Mix magnetic nanospheres with 20mL of PEI aqueous solution with a conc...

Embodiment 3

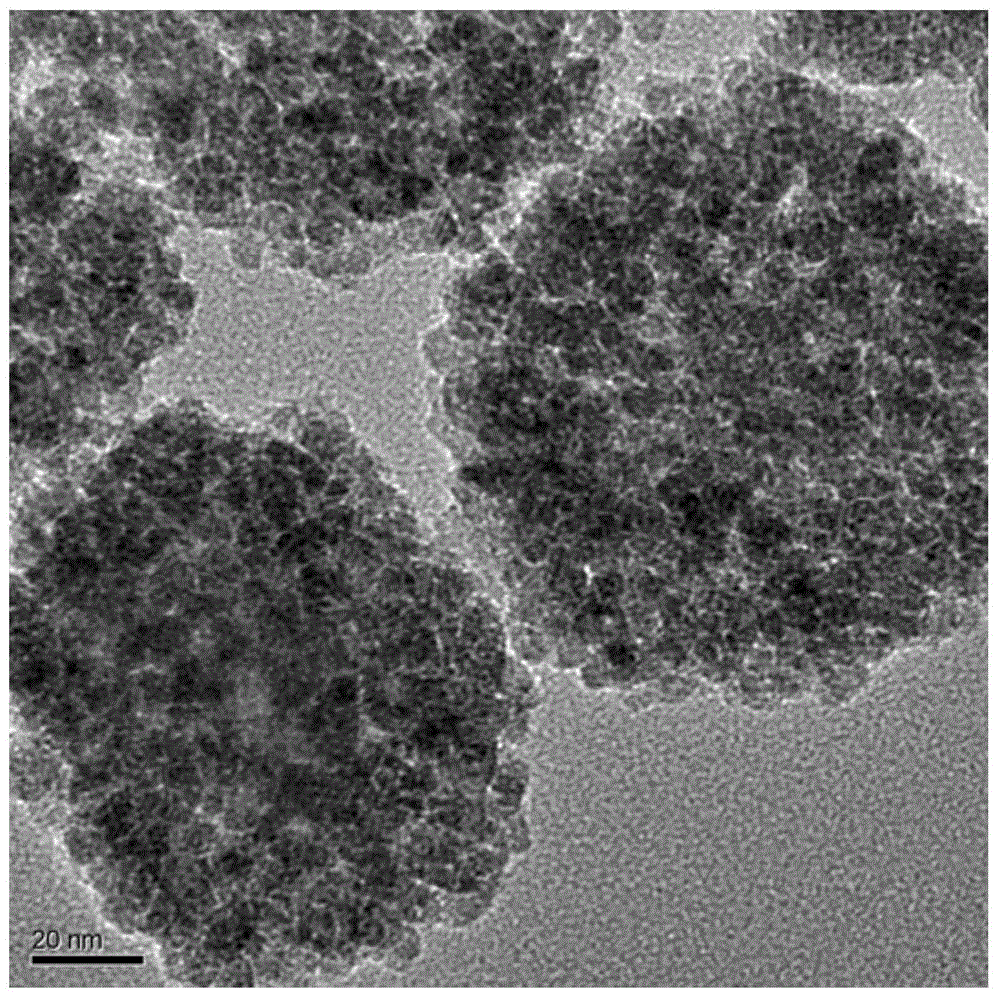

[0045] FeCl 3 ·6H 2 O(2mmol), FeCl 2 4H 2 Add O (1mmol) and sodium acetate (60mmol) into a mixed solvent of 20mL ethylene glycol and 40mL diethylene glycol, stir in a water bath at 70°C for 0.5h, fully dissolve and transfer the resulting solution into a hydrothermal reaction kettle , the temperature was raised to 200°C, and after 12 hours of reaction, it was cooled to room temperature. Magnetic separation, pouring off the waste liquid, washing with absolute ethanol and deionized water, until the magnetic suction clear liquid is colorless, and drying to obtain Fe with a particle size of 500nm 3 o 4 magnetic nanospheres. It is characterized by XRD, the results are shown in Figure 7 , the results show that the positions of the main diffraction peaks are all the same as those of Fe 3 o 4 Corresponding to the standard spectrum, it is Fe 3 o 4 magnetic nanospheres. 0.1g Fe 3 o 4 Magnetic nanospheres were mixed with 20 mL of PEI aqueous solution with a concentration of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com