Undercoat resistant to flushing of high pressure liquid

A technology of high pressure resistance and primer, applied in the direction of coating, epoxy resin coating, polyamide coating, etc., to achieve the effect of prolonging service life and good bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

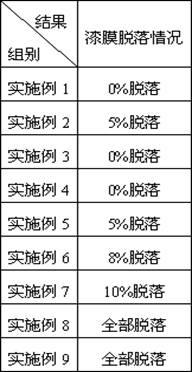

Examples

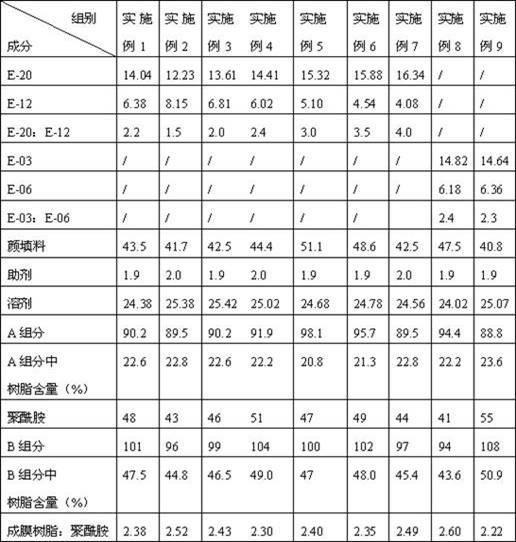

Embodiment 1

[0031] Primers resistant to high pressure liquid washdown are prepared as follows:

[0032] (1) Miscibility of resin

[0033] Put 28 parts of xylene, 9 parts of butanol, and 9 parts of co-solvent into the bottom of the reactor, stir for 10 minutes, add 33 parts of E-20 epoxy resin, 15 parts of E-12 epoxy resin, and control the temperature at 60 Stir at -65°C for 1 hour until it becomes a homogeneous liquid.

[0034] (2) Preparation of component A

[0035] Put 40 parts of the liquid prepared in (1) into the bottom of the reaction kettle, add 0.3 parts of auxiliary agent A, which is a wetting and dispersing agent, stir for 10 minutes, and after uniformity, add 30 parts of anti-rust pigments, 9 Part filler, 4.5 parts titanium dioxide, after stirring for 2 hours, perform mechanical grinding until the fineness is 40um, add 1.6 parts of auxiliary agent B, 4.8 parts of cyclohexanone, auxiliary agent B is leveling agent, coupling agent, and stir evenly .

[0036] (3) Preparation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com