Subway-inspection-pit small stand column and rail integral construction structure and method

A kind of inspection pit and integrated technology, which is applied in the direction of track, track laying, track maintenance, etc., can solve the problems of small column missing corners, damage, and accuracy that cannot meet the accuracy of rail laying I, so as to save construction period, avoid secondary adjustment, The effect of avoiding finished product protection problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

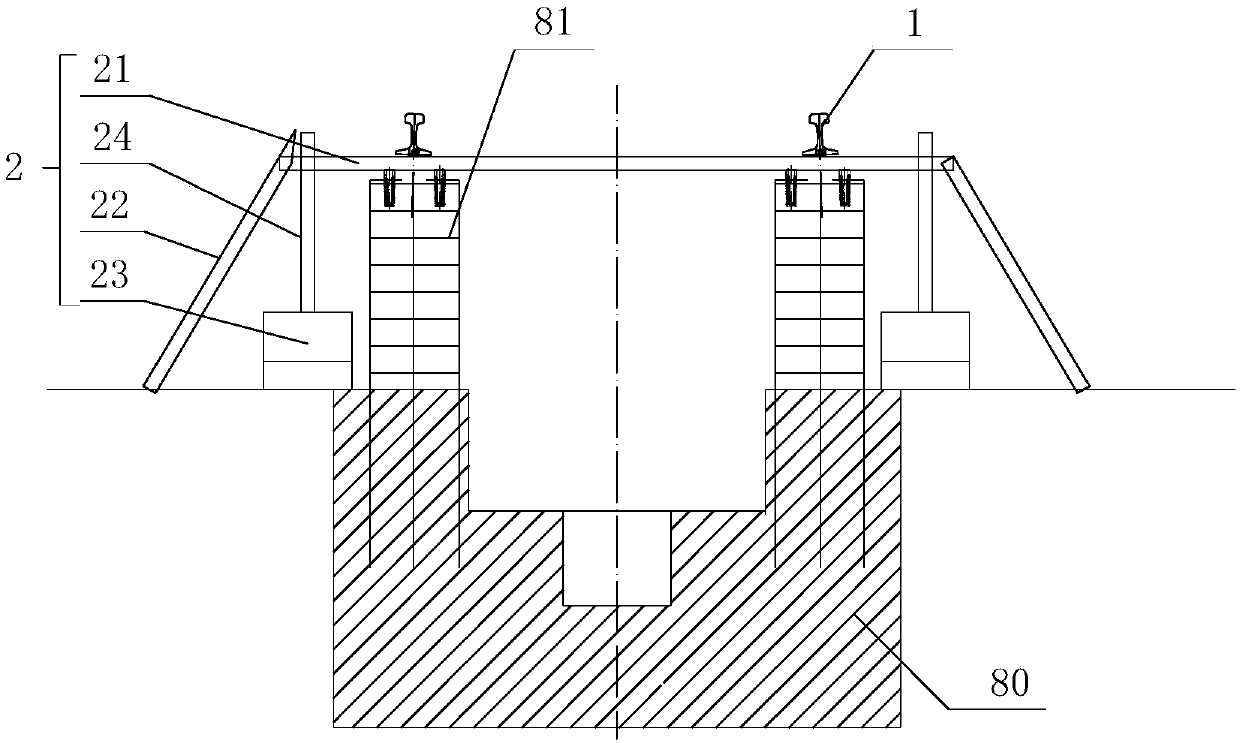

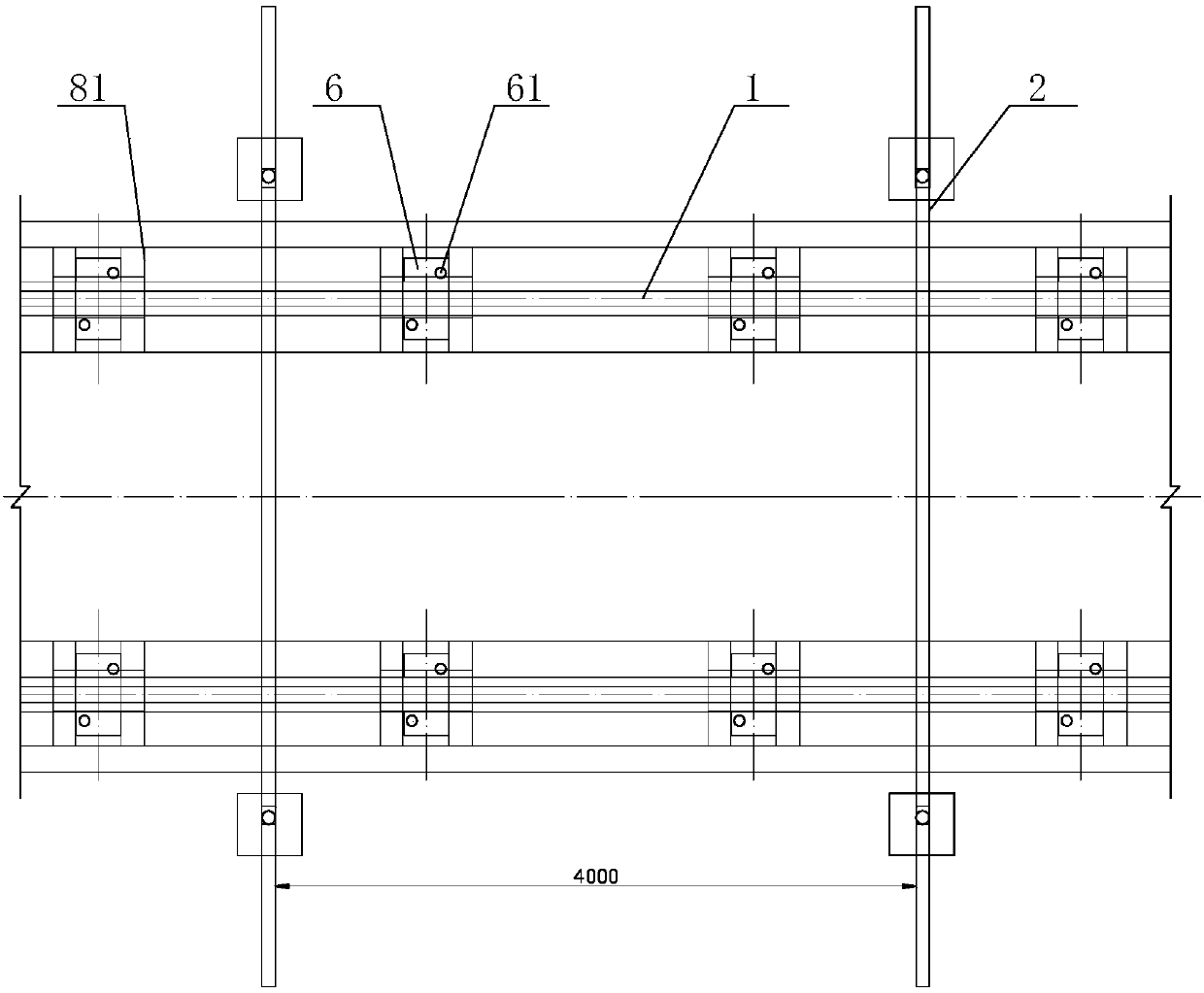

[0042] read on Figures 1 to 5 , the present embodiment discloses a method for integrally constructing the small columns and tracks of the subway inspection pit, using the integral construction of the small columns 8 and the track 1 of the subway inspection pit as described in Embodiment 1, and the method includes the following steps:

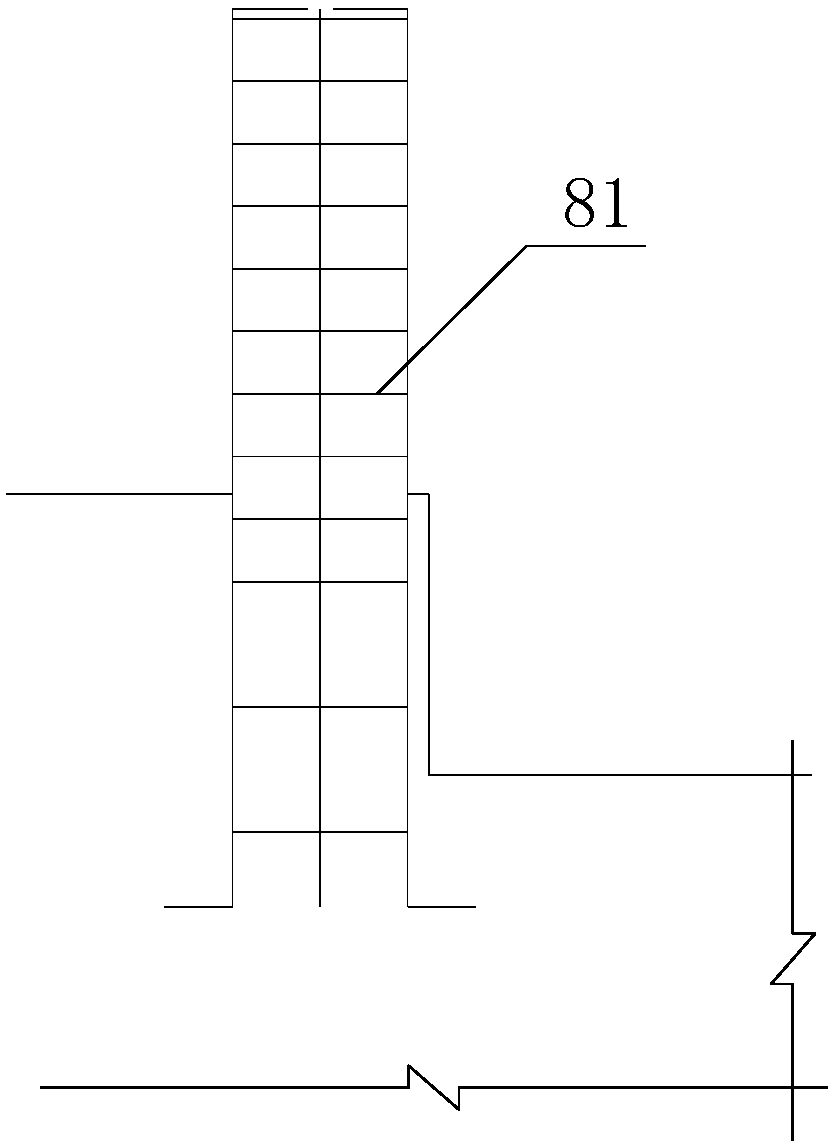

[0043] Step 1, please refer to image 3 , Carry out the steel bar binding work of the small column 8 of the inspection pit.

[0044] Step two, see figure 1 with figure 2 , set up the track supporting frame 2 that erects track 1 usefulness, and track supporting frame 2 adopts I-beam, and track supporting frame 2 is provided with one every 3-5 meters.

[0045] Step 3, please focus on continuing to read figure 1 with figure 2 , to erect track 1.

[0046] Step 4, please focus on continuing to refer to figure 1 with figure 2 , the bolt embedded sleeve 3 is fixed below the track 1, and the bolt embedded sleeve 3 extends into the small colu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com