Modular cultivation method for heavy metal hyper-accumulating plants

A cultivation method and heavy metal technology, applied in the field of soil phytoremediation, can solve the problems of high labor cost, low biomass, slow growth, etc., and achieve the effect of reducing labor cost, obvious comprehensive effect, and uniform planting density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

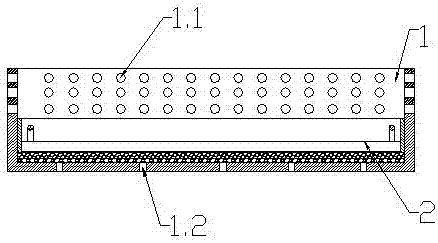

[0028] The modular cultivation method of heavy metal hyperaccumulator plants (such as Sedum sedum) is realized through the following steps, such as figure 1 , figure 2 Shown:

[0029] In the experiment, sedum sedum was interplanted under corn crops, considering the shade-loving characteristics of sedum sedum, and maize was mainly cultivated in crop fields with heavy metal cadmium exceeding the standard, and then sedum sedum was interplanted with heavy metal overaccumulation plant sedum sedum.

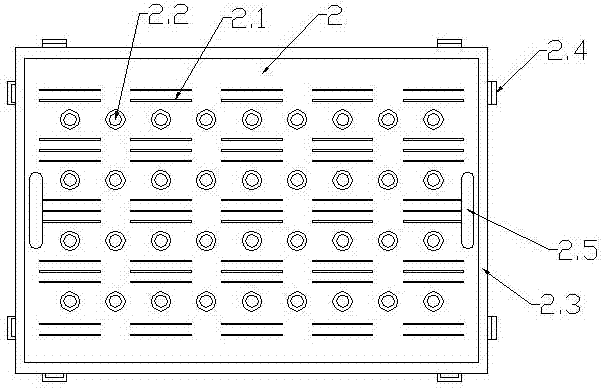

[0030] (1) Module box preparation: Prepare multiple rectangular, rain-resistant and weather-resistant rubber or resin material-specific module boxes. The structure of a module box is divided into two parts: one part is the box body 1, and its size is 63cm long x 43cm wide ×Height 16cm, without cover, the surrounding wall of the box body 1 is a plate structure with holes 1.1 in the upper half and no holes in the lower half. The bottom of the box body 1 is a stressed plate with a small ...

Embodiment 2

[0041] The modular cultivation method of heavy metal copper Cu hyperaccumulation plants such as Commelina is realized by the following steps, such as figure 1 , image 3 Shown:

[0042] (1) Preparation of the module box: Prepare multiple rectangular resin-based material-specific module boxes. A module box structure is divided into two parts: one part is the box body 1, and its size is 63cm in length x 43cm in width x 16cm in height. Without a cover, the walls around the box body 1 have a structure with holes 1.1 in the upper half and no holes in the lower half. The bottom of the box body 1 is a flat plate with a small amount of drainage holes 1.2; the other part is a solid frame 2 through the root, It is a soft cloth-like structure of 60cm x width 40cm x thickness 0.2cm. The root-permeable solid frame 2 is evenly distributed with long strips of pores 2.1 of length 8cm x width 0.18cm x thickness 0.2cm, which is convenient for the root system. It penetrates downwards, and ther...

Embodiment 3

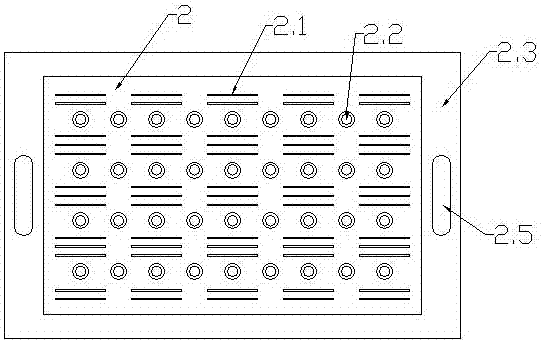

[0050] Embodiment three (such as figure 1 , Figure 4 shown)

[0051] Except above-mentioned embodiment, the penetrating root solid frame 2 of the present invention can also be made: a plurality of single penetrating root solid frames are formed side by side, and each single penetrating root solid frame comprises a plurality of weed blocking boards 2.6, and connects adjacent two The force-bearing connection belt 2.7 of a grass-separating board 2.6, wherein each small round planting hole 2.2 is correspondingly arranged on the grass-separating board 2.6, and the elongated thin hole 2.1 is formed between two adjacent through-root solid frames placed side by side. gaps between them are formed. It is convenient for seedling raising, transplanting and harvesting.

[0052] The invention relates to a method for planting and cultivating fibrous root plants in a system that saves labor, seeds (seedlings), fertilizer and grass. Especially for the phytoremediation of heavy metal-conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com