Tea-leaf single-bud tea picking machine

A tea picking machine and single-bud technology, which is applied in the field of tea single-bud tea picking machines, can solve problems such as low work efficiency, high labor intensity, and affecting the quality of finished tea

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

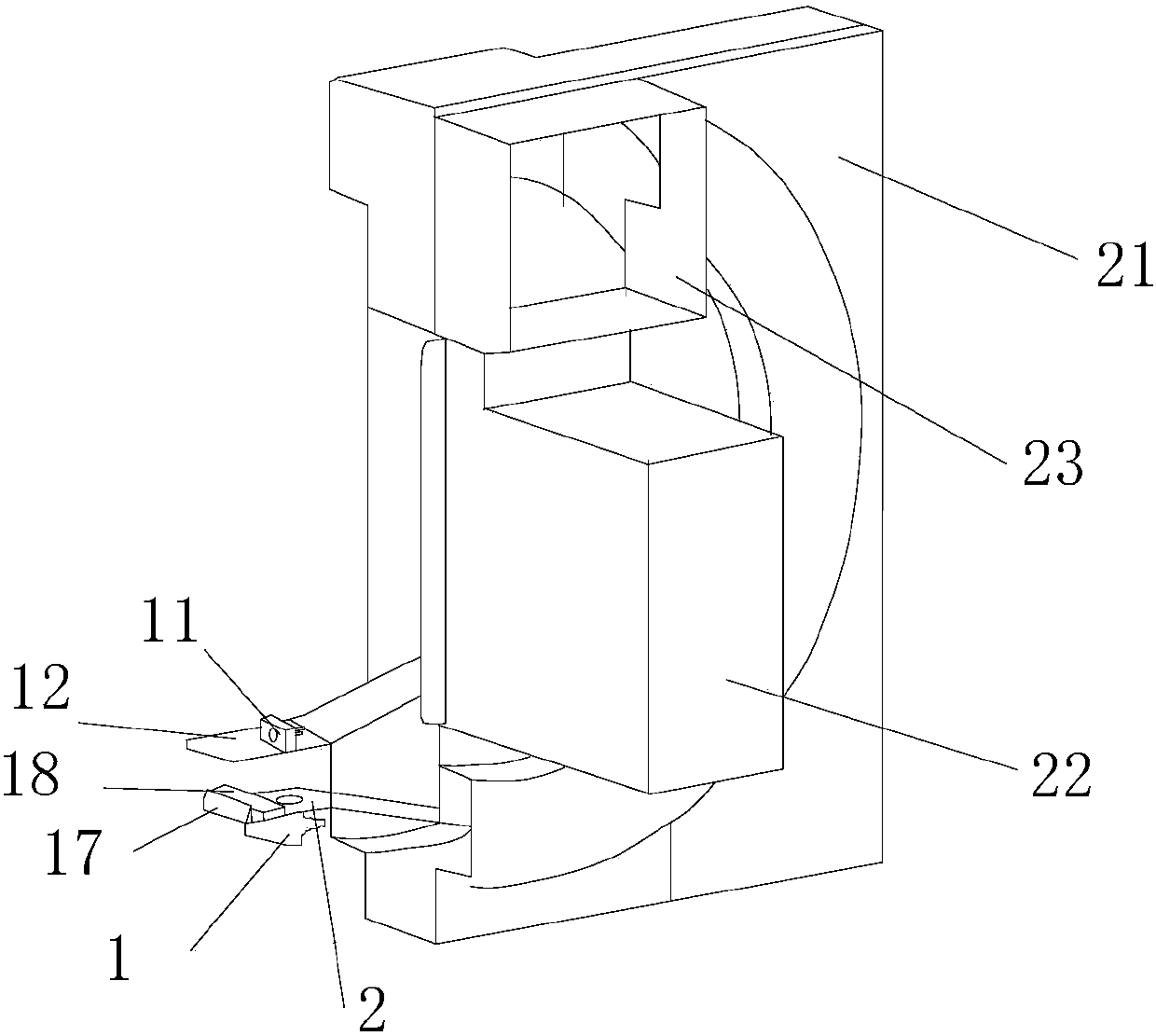

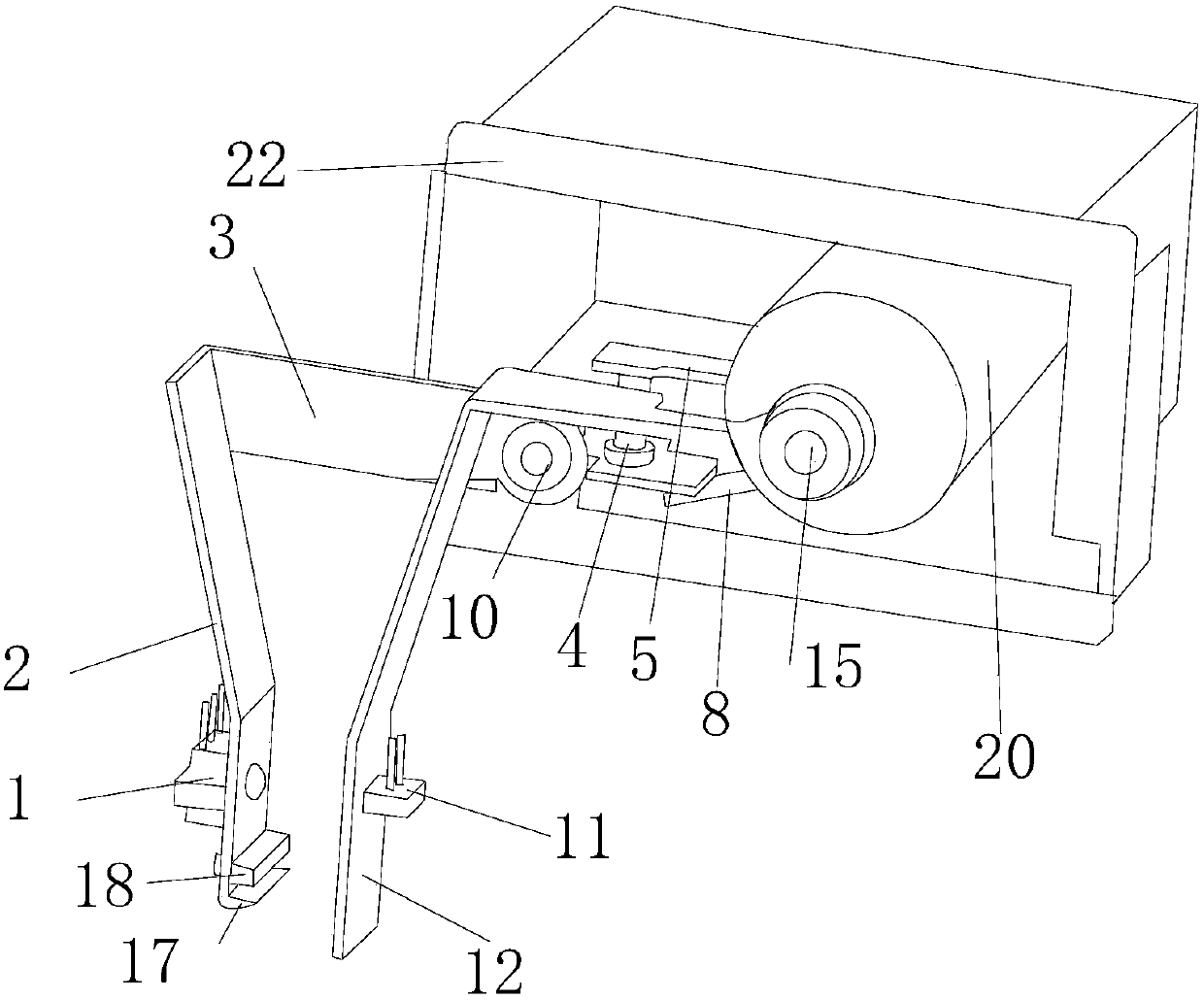

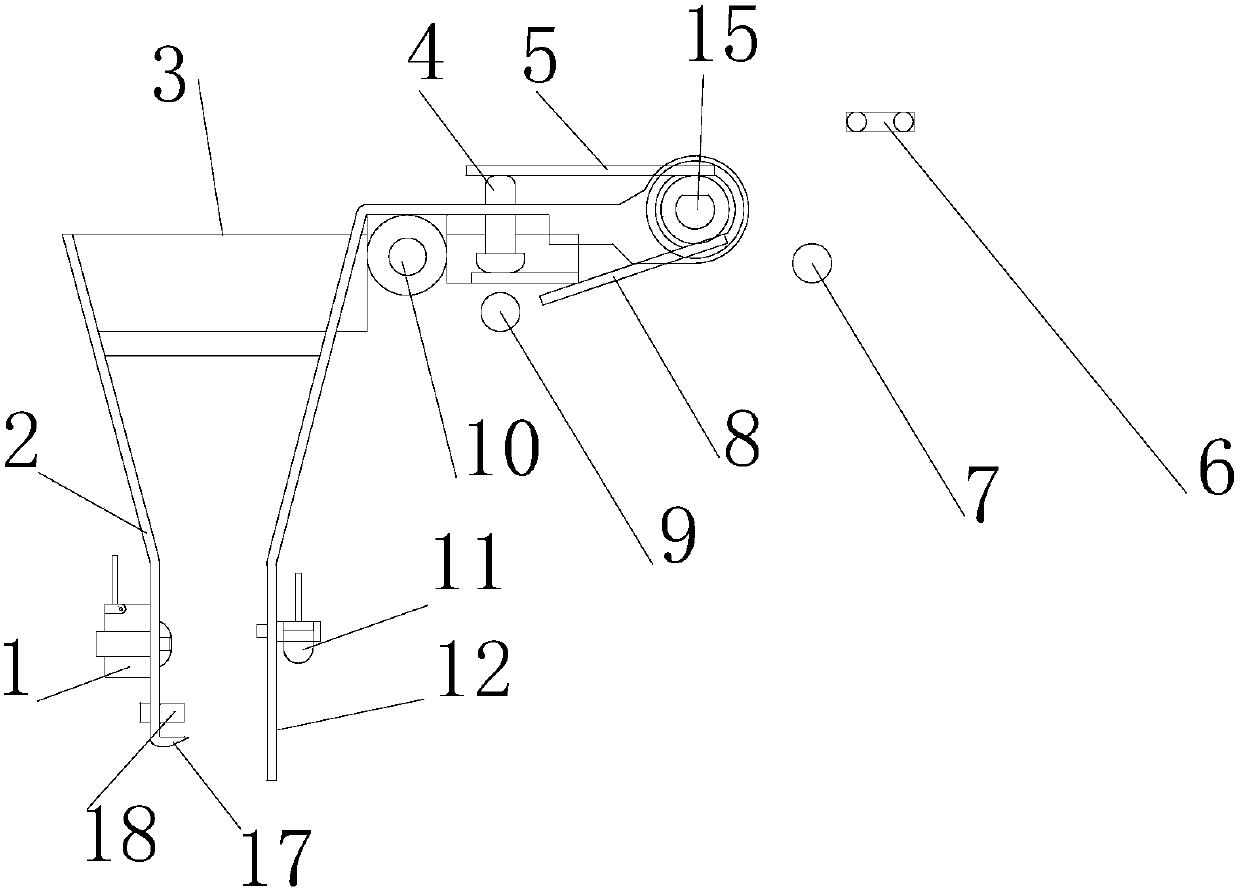

[0018] like Figure 1-5 As shown, the tea single-bud tea picking machine of the present invention includes a housing 21, a motor housing 22 and a tea outlet 23, the motor housing 22 and the tea outlet 23 are arranged on the housing 21, and the motor housing 22 A motor 20 is arranged inside, and the housing 21 is provided with a motor bearing 15, a limit post 7, a stop switch, a stop post 9 and a reset induction switch 6, and the motor 20 is drivingly connected to the motor bearing 15, and the motor bearing 15 is provided with a reset push block 5 and a cutting push block 8, the motor bearing 15 is movably connected with the rotating shaft 10, a cutting finger 2 and a main finger 12, and the cutting finger 2 and the main finger 12 move through the support member 3 Connected, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com