Gear groove combined male die for warm header

A gear groove, warm heading machine technology, applied in forging/pressing/hammering machinery, manufacturing tools, forging/pressing/hammer devices, etc., can solve the problems of wasting materials, affecting the processing of gear grooves, and easy deformation of groove heads. To achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In the following, with reference to the accompanying drawings and preferred embodiments, the implementation, structure, features and functions of the combined male mold body for gear grooves for warm heading machines according to the present invention will be described in detail as follows.

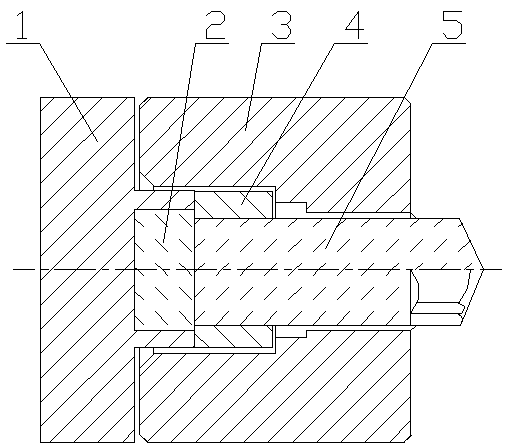

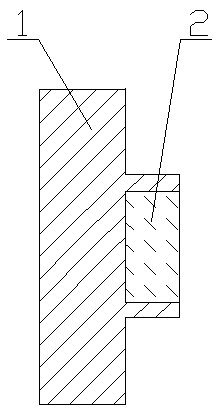

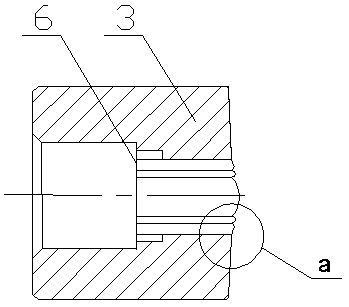

[0020] see Figure 1 to Figure 6 , the gear groove combination positive mold for warm heading machine of the present invention, including pad 1, punch cover 3, punch 5, wherein: punch cover 3 is equipped with punch 5 inside, and the head of punch 5 is placed in punch cover 3 Externally, the tail of the punch 5 is fixedly connected with a fixed sleeve 4, and the fixed sleeve 4 is placed on the end face of the step 6 of the punch sleeve 3, and the rear part of the fixed sleeve 4 is pressed with a pad 1, and the cavity of the pad 1 is equipped with a pad core 2. The pad core 2 is placed at the end of the punch 5 . The tail of the punch cover 3 is provided with a chamfer, and the end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com