Spunlace non-woven fabric production technology

A spunlace non-woven fabric and production process technology, applied in the textile field, can solve the problems of non-environmental protection and high production process costs, achieve the effects of low power consumption, improve production efficiency, and avoid uneven bleaching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present application will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

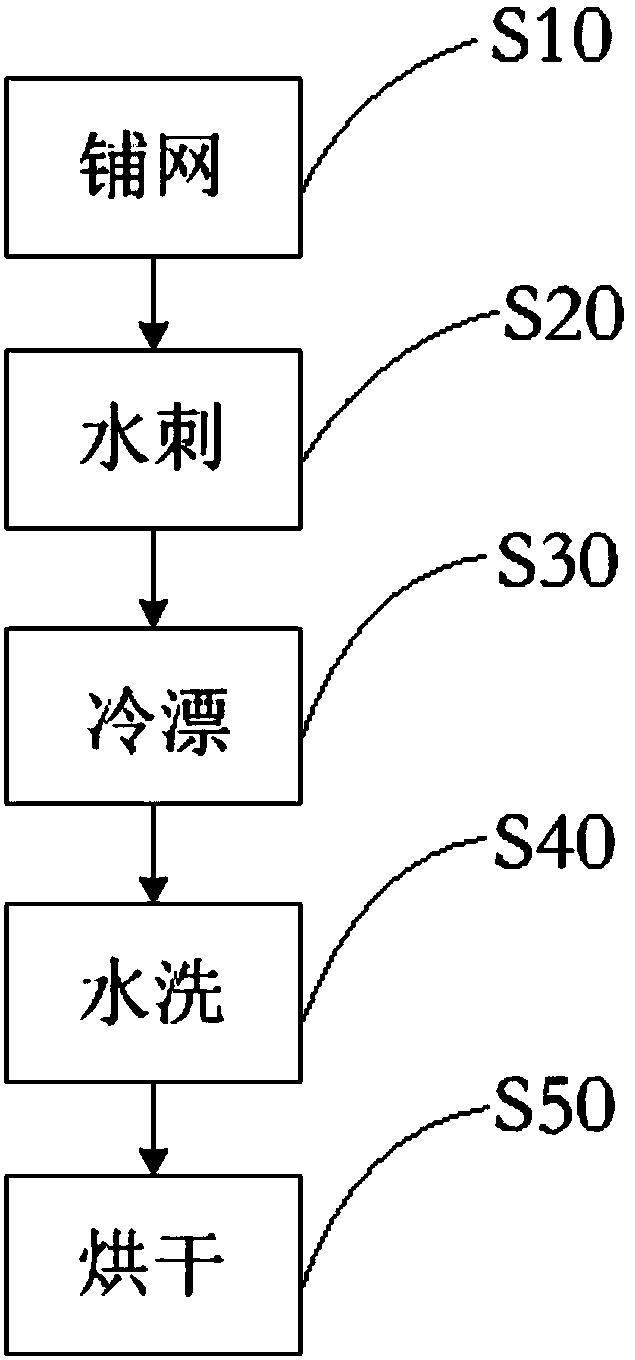

[0023] The production technology of the spunlace non-woven fabric provided in the present embodiment is as follows figure 1 shown, including the following steps,

[0024] S10, laying net

[0025] The raw cotton fibers that have been cleaned and carded are laid by a web laying machine to form a cotton web.

[0026] S20, Spunlace

[0027] The cotton web is spunlaced through a high-pressure water curtain to form a spunlace non-woven fabric.

[0028] S30, cold drift

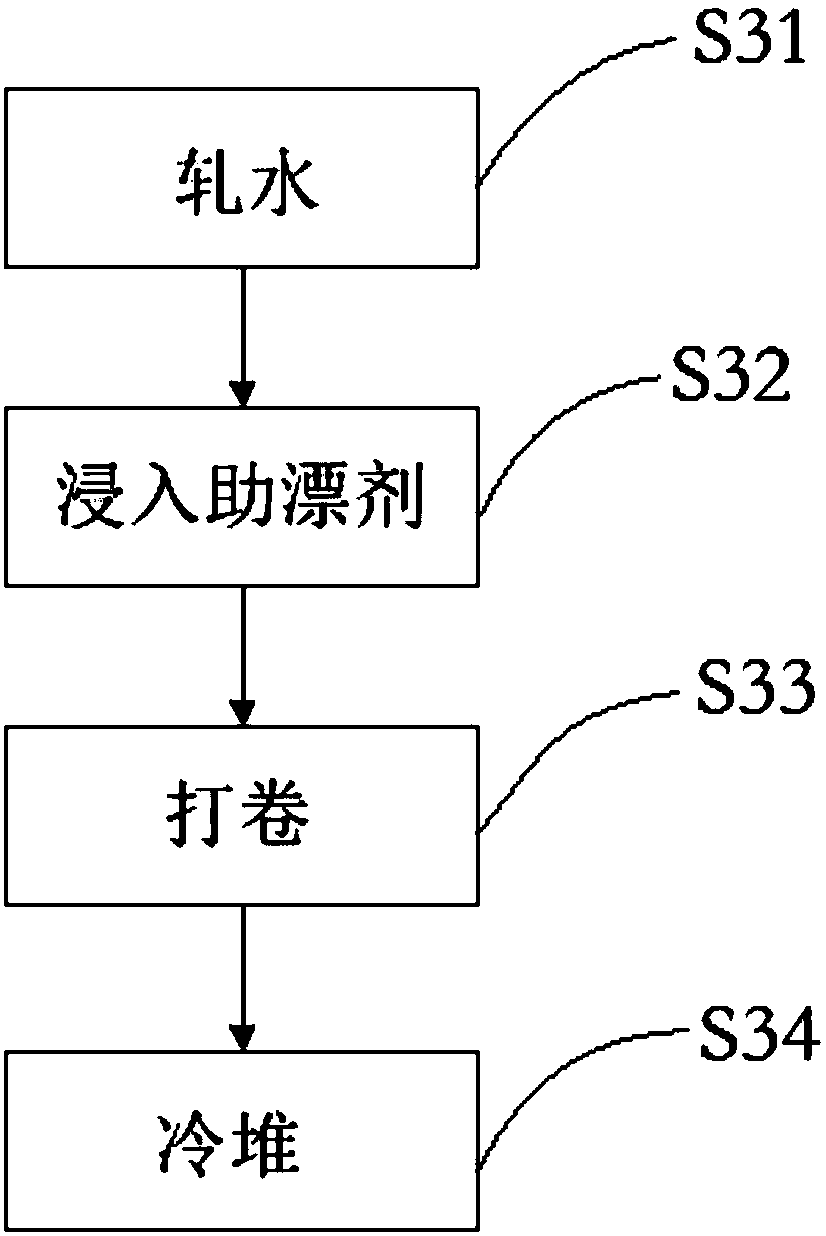

[0029] The spunlace non-woven fabric is treated by cold bleaching. Specifically as figure 2 shown, including:

[0030] S31, rolling water;

[0031] The spunlace non-woven fabric is subjected to a high-efficiency rolling mill for water-rolling treatment to reduce its moisture content, so that the moisture content in the non-woven fabric is reduced from 150%-400...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com