Production technology of spunlaced non-woven fabric

A technology of spunlace non-woven fabric and production process, which is applied in non-woven fabrics, textiles and papermaking, and liquid/gas/vapor removal with squeeze rollers, etc. Low power consumption, low water consumption, avoiding the effect of uneven bleaching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present application will be described in further detail below through specific embodiments in conjunction with the accompanying drawings.

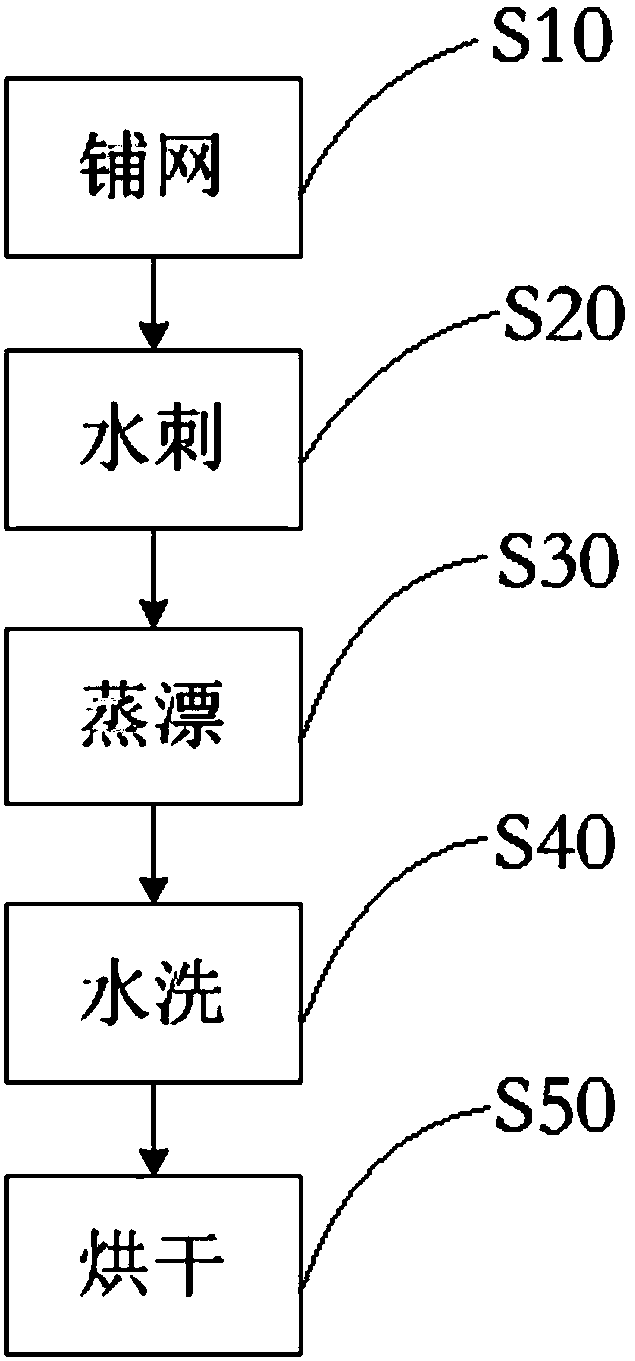

[0022] The production process of the spunlace non-woven fabric given in this embodiment is as follows: figure 1 shown, including the following steps,

[0023] S10, laying net

[0024] Lay the raw cotton fiber after cleaning and carding through a web-laying machine to form a cotton web.

[0025] S20, spunlace

[0026] Spunlace the cotton web through a high-pressure water curtain to form a spunlace nonwoven fabric.

[0027] S30, steam bleaching

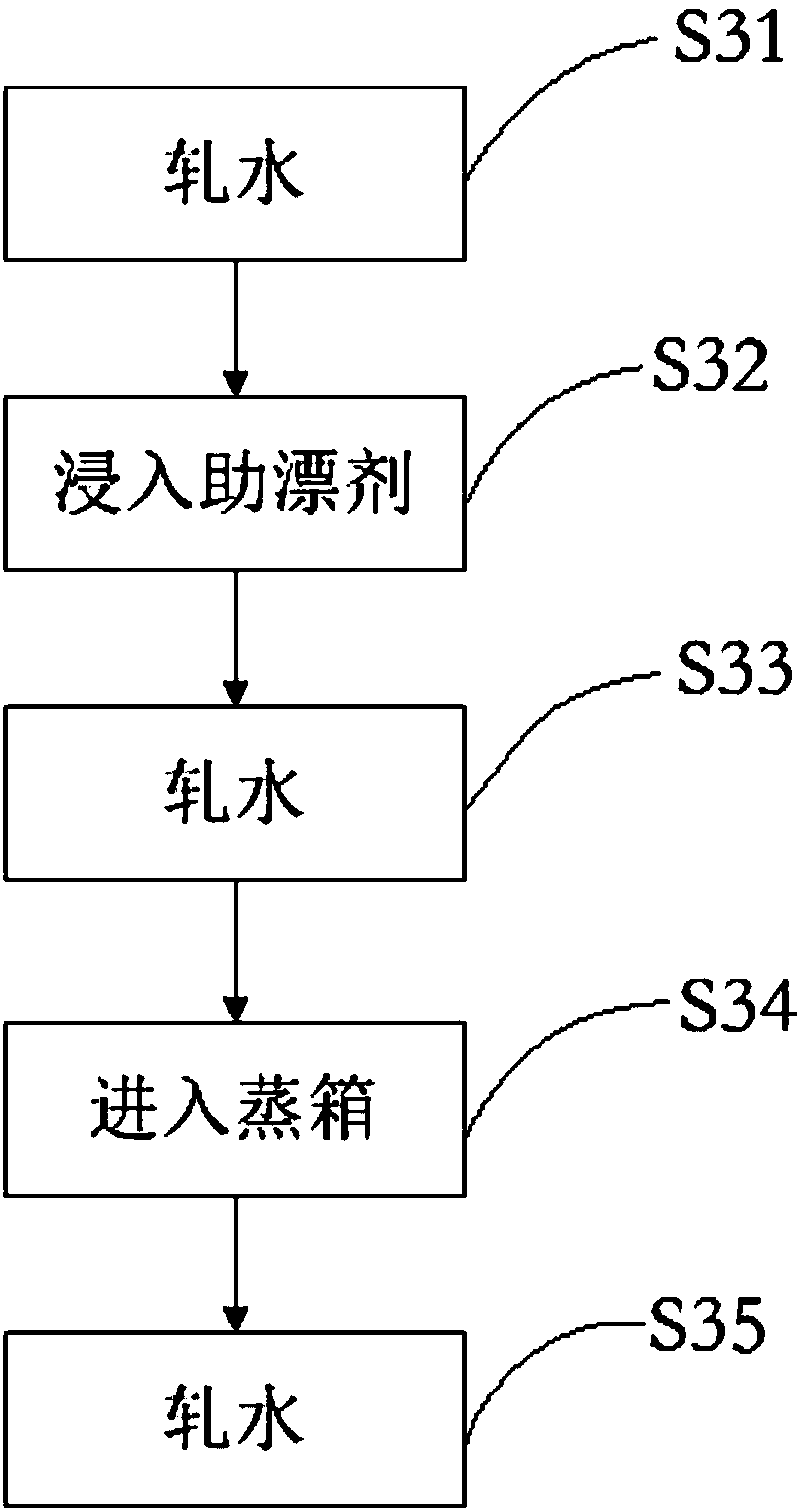

[0028] The spunlace non-woven fabric is steam bleached through a steam box. Specifically as figure 2 shown, including:

[0029] S31, squeezing water;

[0030] Reduce the moisture content of the non-woven fabric after spunlace by padding, and reduce the moisture content in the non-woven fabric from 150%-400% to 50%-100%. In this step, the non-woven fabric after spunlace does not n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com