Rock-inserted steel pipe pile load test device and method under cyclic loading effect

A technology of loading test device and steel pipe pile, which is applied in the test of basic structure, construction, and basic structure engineering, etc., can solve the problems of weak rock-socketing depth, rare in-depth system, and high test cost, and achieves convenient operation and test data. Accurate, high-frequency test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

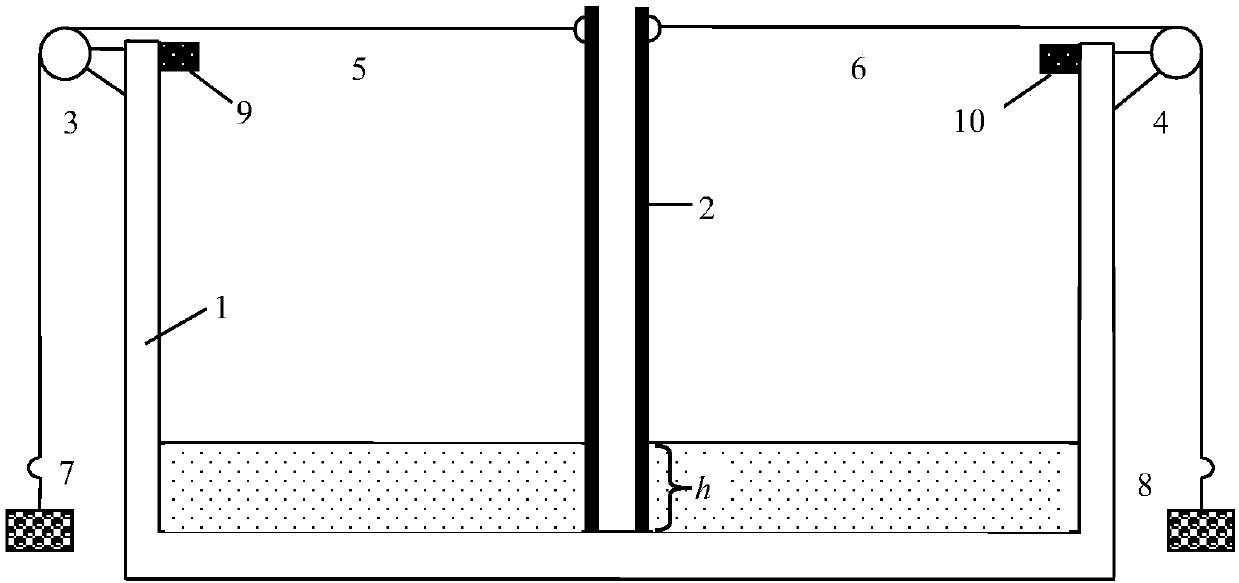

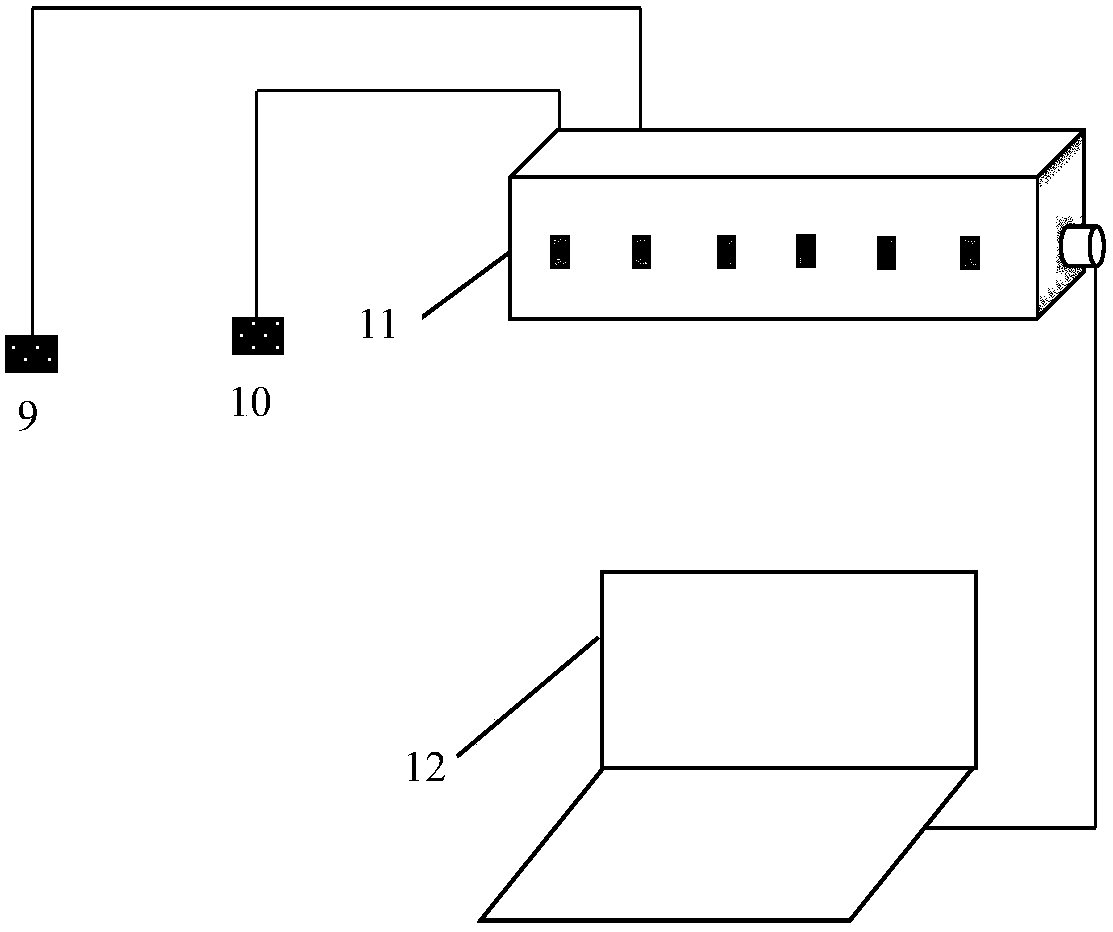

[0017] The main structure of the rock-socketed steel pipe pile loading test device under the action of cyclic load in this embodiment includes a rectangular model box 1, a model steel pipe pile 2, a first directional pulley 3, a second directional pulley 4, a first slender steel wire 5. The second elongated steel wire 6, the first loading weight 7, the second loading weight 8, the first laser displacement sensor 9, the second laser displacement sensor 10, the data collector 11 and the computer 12; the model steel pipe pile 2 Vertically installed in the middle of the rectangular model box 1, the first directional pulley 3 and the second directional pulley 4 are respectively fixedly installed on the top outer walls of the left and right sides of the rectangular model box 1, and the first slender steel wire 5 is installed on the first On the directional pulley 3, one end of the first slender steel wire 5 is fixed on the model steel pipe pile 2, and the other end is applied with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com