Glass with self-cleaning function, manufacturing method thereof and wall containing glass

A self-cleaning, manufacturing method technology, applied to walls, insulation, building components, etc., can solve the problems of cleaning personnel climbing and cleaning, unfavorable cleaning personnel's personal safety, low cleaning efficiency, etc., and achieve good heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

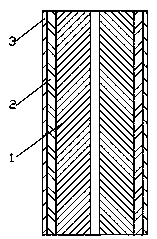

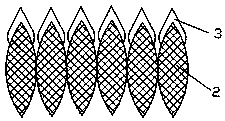

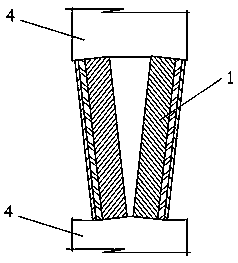

[0020] like figure 1 and figure 2 As shown, a self-cleaning glass according to an embodiment of the present invention includes two glass units. Each glass unit includes a base body 1 and a nano layer 2 coated on one side of the base body 1 . The nanometer layer 2 is formed by interconnecting rugby-shaped nanoparticles, and there is a gap between the nanometer layer 2 and the matrix 1 . A hydrophobic layer 3 is provided at the end of the nanoparticles away from the substrate 1 . The two glass units are arranged oppositely, and a vacuum cavity is formed between the substrates 1, and the nanometer layer 2 is located outside the vacuum cavity.

[0021] In the glass structure of the above embodiment, each glass unit includes a base 1 and a nano-layer 2 coated on one side of the base 1 , and there is a gap between the nano-layer 2 and the bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com