Fan blade structure and rotor set thereof

A fan blade and joint technology, which is applied to the components of pumping devices for elastic fluids, non-variable displacement pumps, machines/engines, etc., can solve noise, local thermal stress at the fan blade end, material Fatigue, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

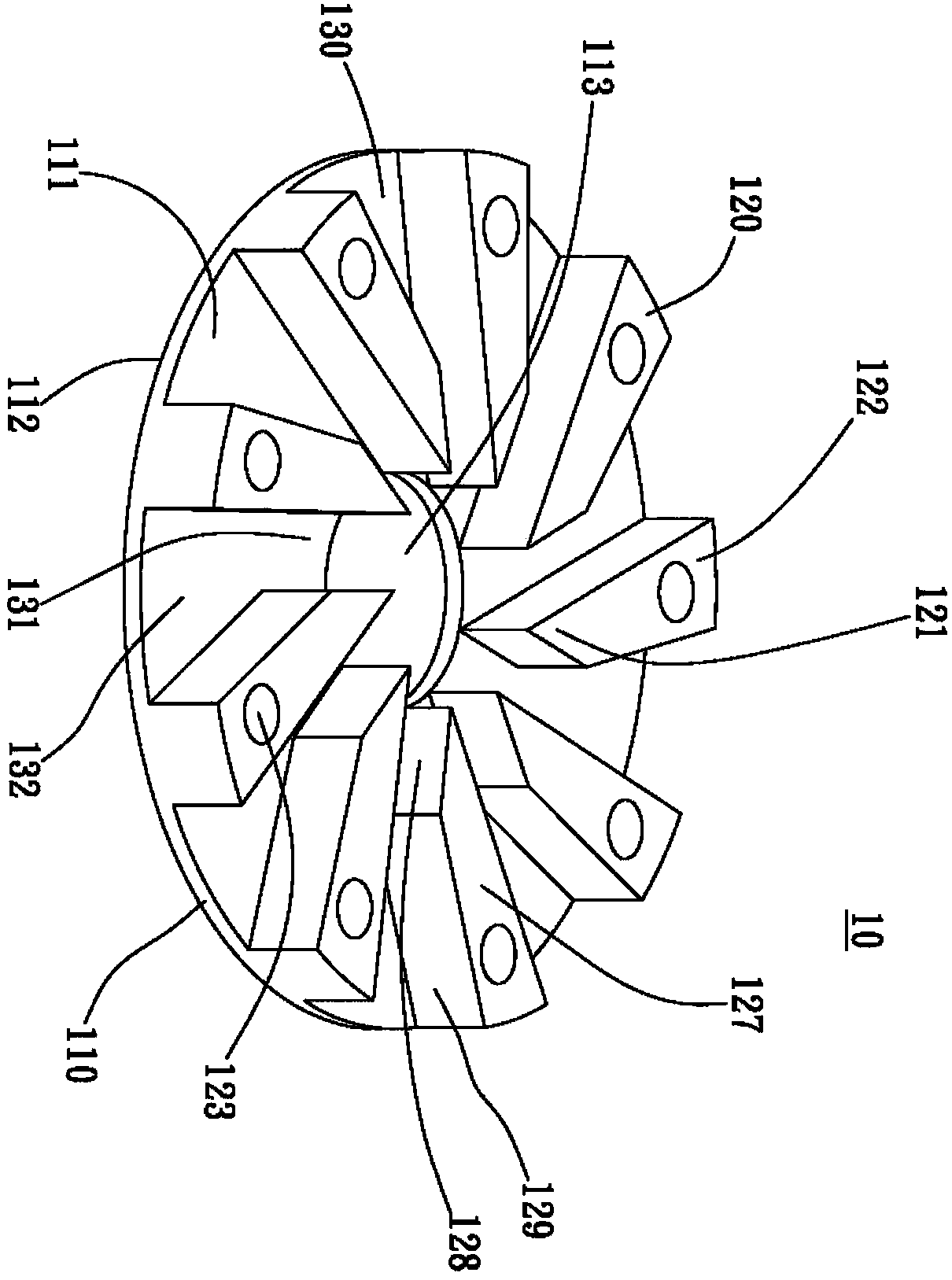

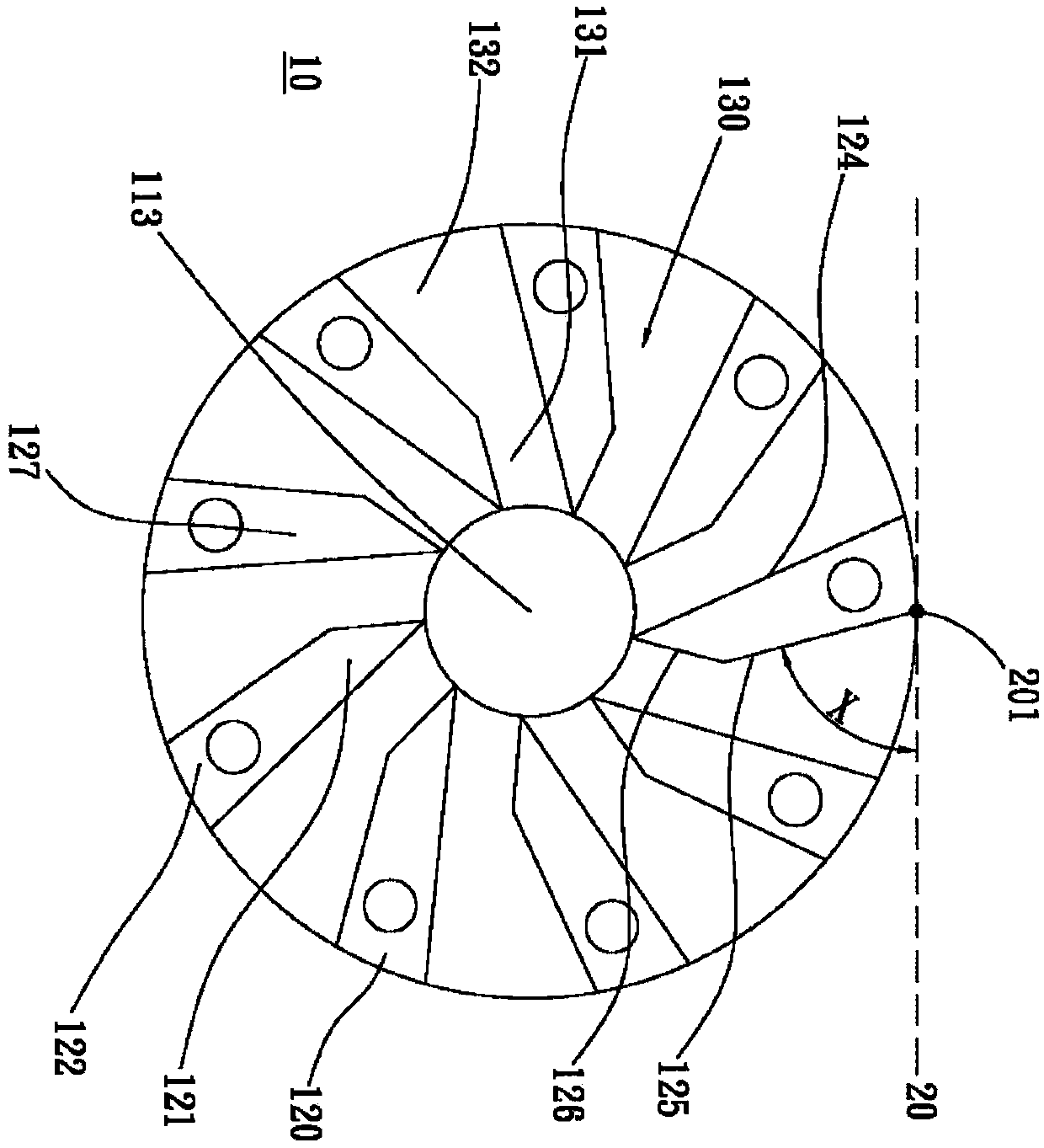

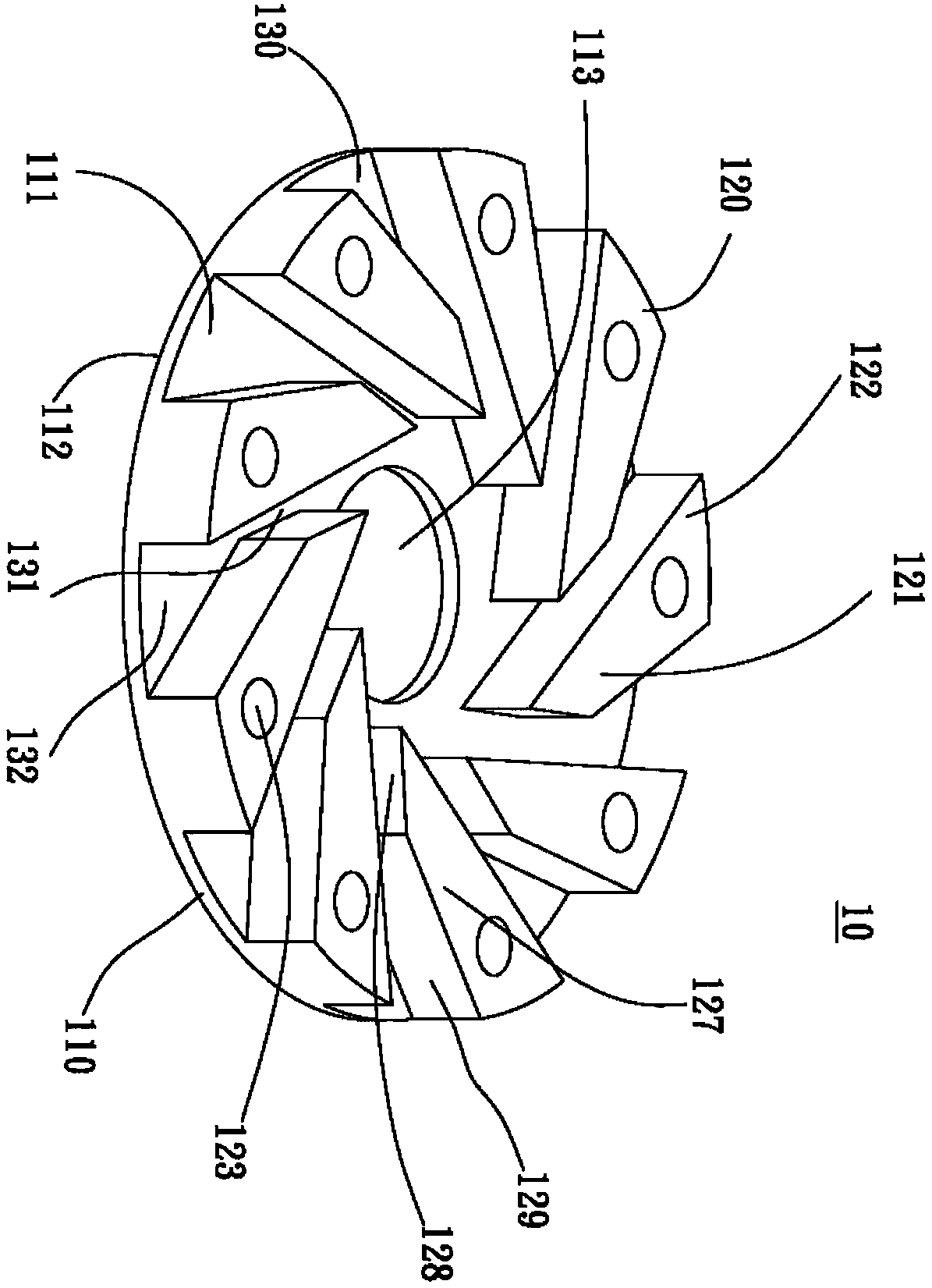

[0050] The above-mentioned purpose of the present invention and its structural and functional characteristics will be described based on the preferred embodiments of the accompanying drawings.

[0051] see figure 1 and figure 2 , is a perspective view and a top view of the first embodiment of the fan blade structure of the present invention. As shown in the figure, the fan blade structure 10 of the present invention includes a body 110. In this embodiment, the fan blade structure 10 is represented as It is applied in a pumping chamber (not shown) of a water-cooled heat dissipation module, but it is not limited thereto. In other embodiments, the fan blade structure 10 can also be applied in other types of pumping chambers. The application of the fan blade structure 10 is not limited by the invention.

[0052] The body 110 has a first side 111, a second side 112 and a first through hole 113, the first side 111 is located on the upper side of the body 110, the second side 112 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com