Non-decompression opening equipment for pipe fitting

A technology of equipment and pipe fittings, applied in the field of non-depressurized opening equipment, to achieve the effect of improving installation efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

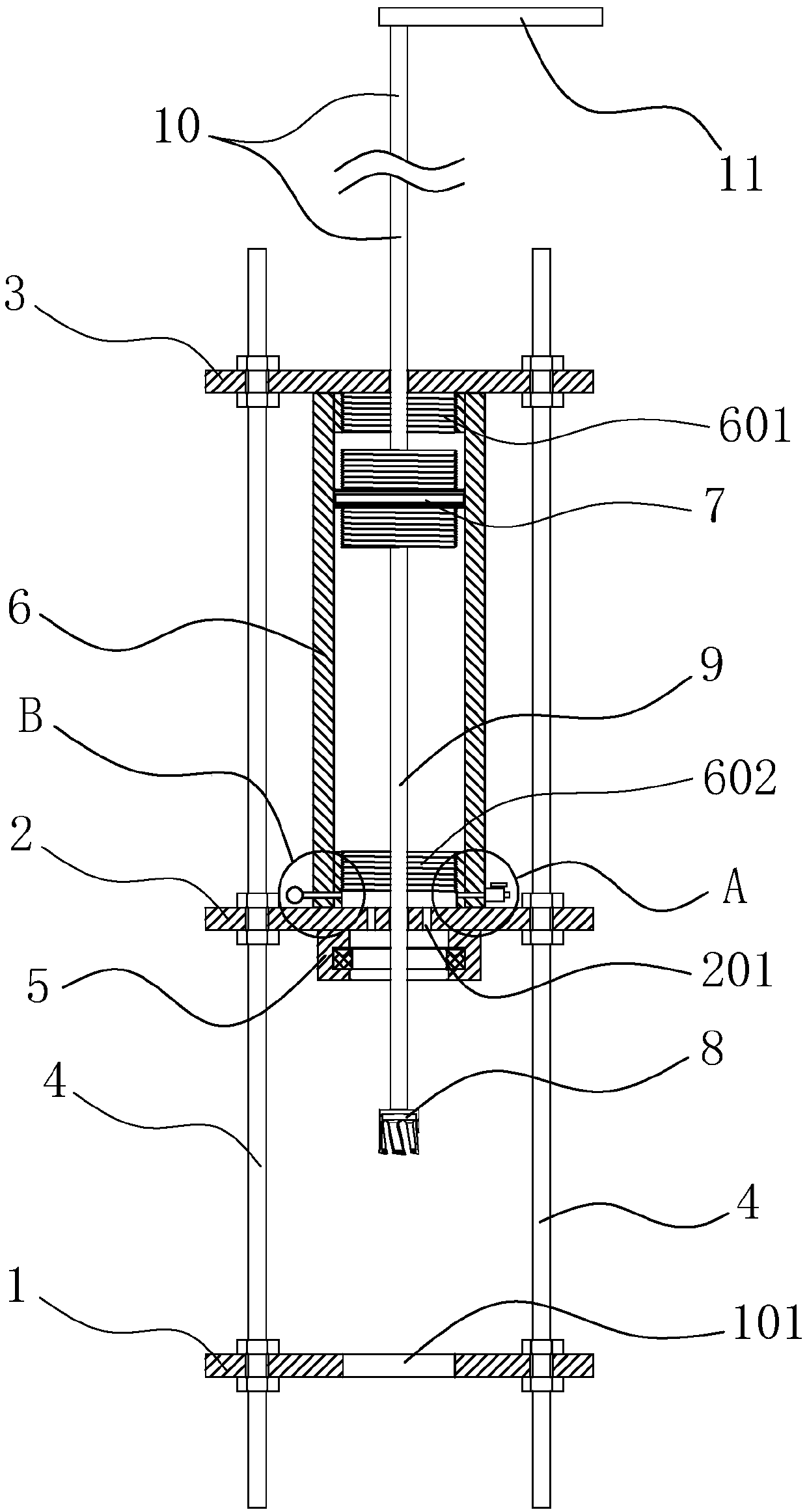

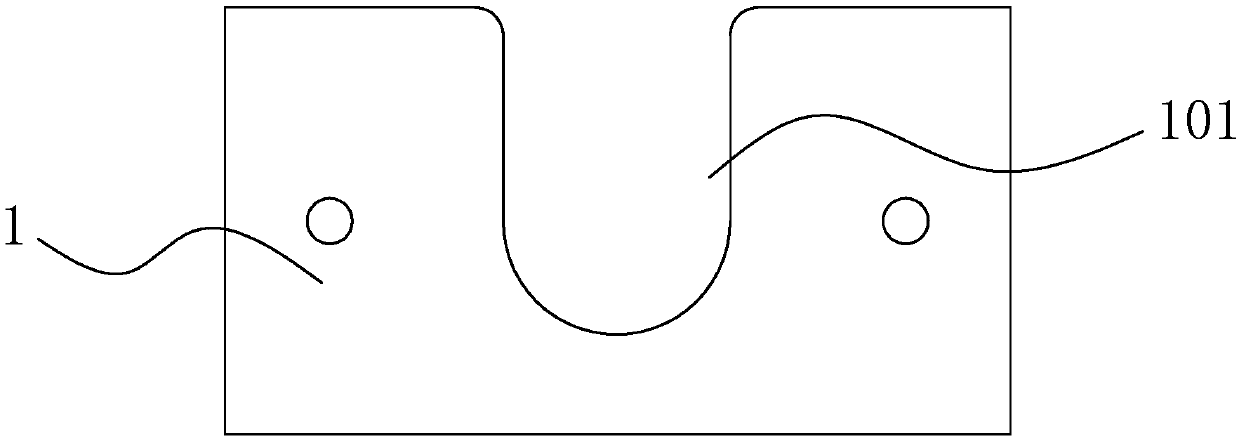

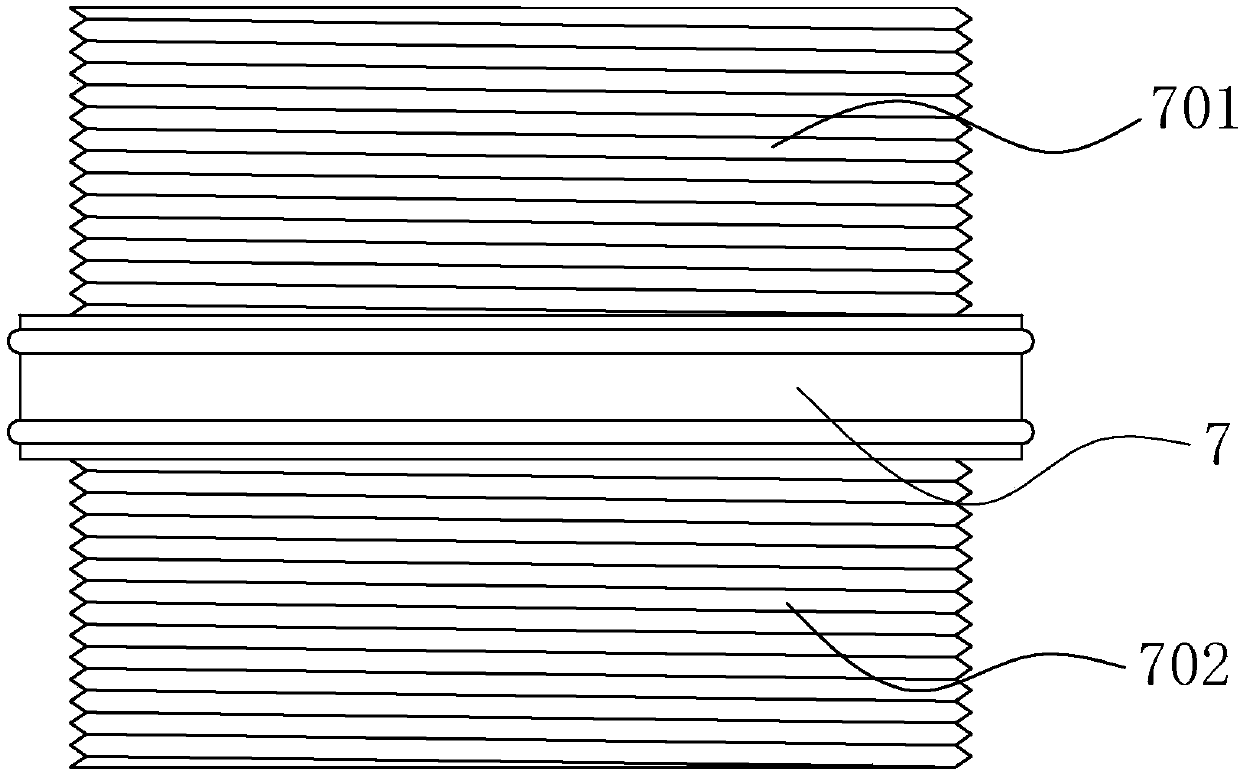

[0030] A non-relief opening device for pipe fittings, see Figure 1 to Figure 12 , including two screw rods 4, the two screw rods 4 are arranged in parallel, and the two screw rods 4 are sequentially positioned with a clamping plate 1, a sealing plate 2 and a positioning plate 3, and the clamping plate 1, the sealing plate 2 and the positioning plate 3 are fixed in parallel by the nuts screwed on the screw rod 4, and can be disassembled or adjusted by adjusting the distance between the adjacent plates. The bayonet 101 that matches the connecting arm of the ball valve 12 is provided on the clamping plate 1, such as figure 2 shown. A sealing end cover 5 is provided on the side of the sealing plate 2 towards the clamping plate 1, such as Figure 4 , Figure 5 As shown, the sealing end cap 5 is used to seal one end port of the ball valve 12, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com