Light strip plug

A technology of light strips and power connectors, which is applied to lighting devices, components of lighting devices, light source fixing, etc., can solve problems such as inconvenient operation and use, high voltage unsafe, etc., and achieve the effect of preventing accidental electric shock and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

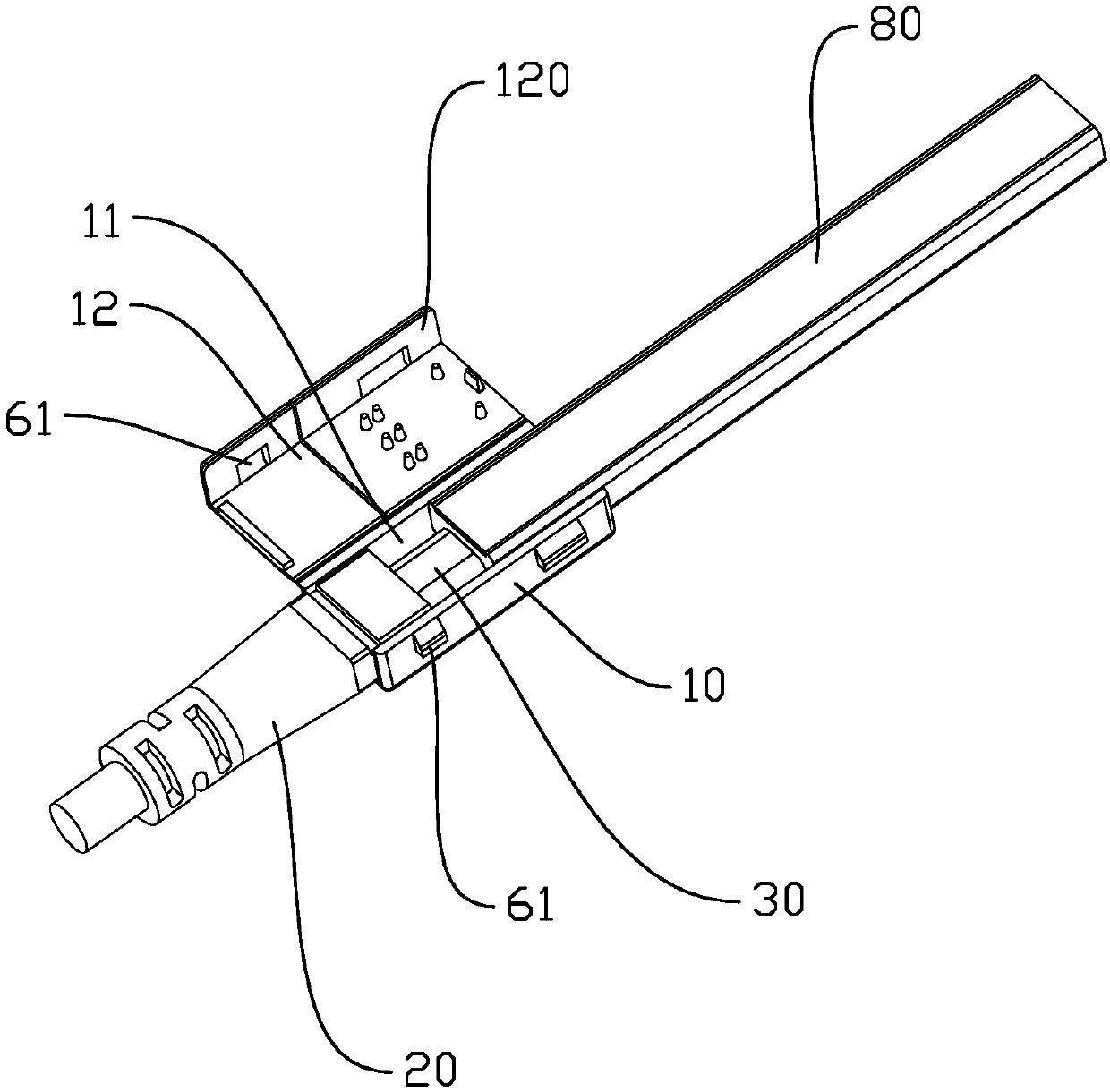

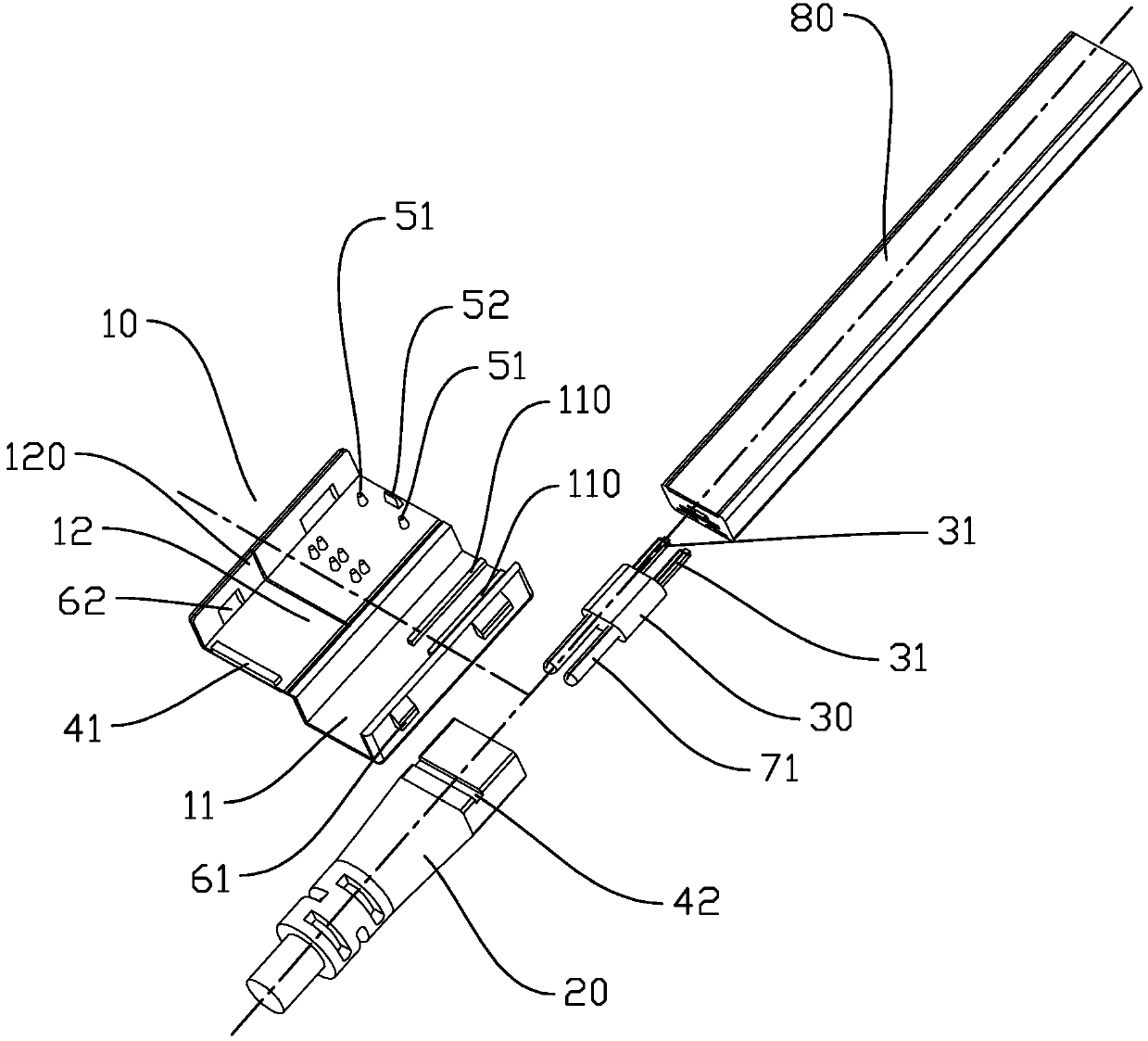

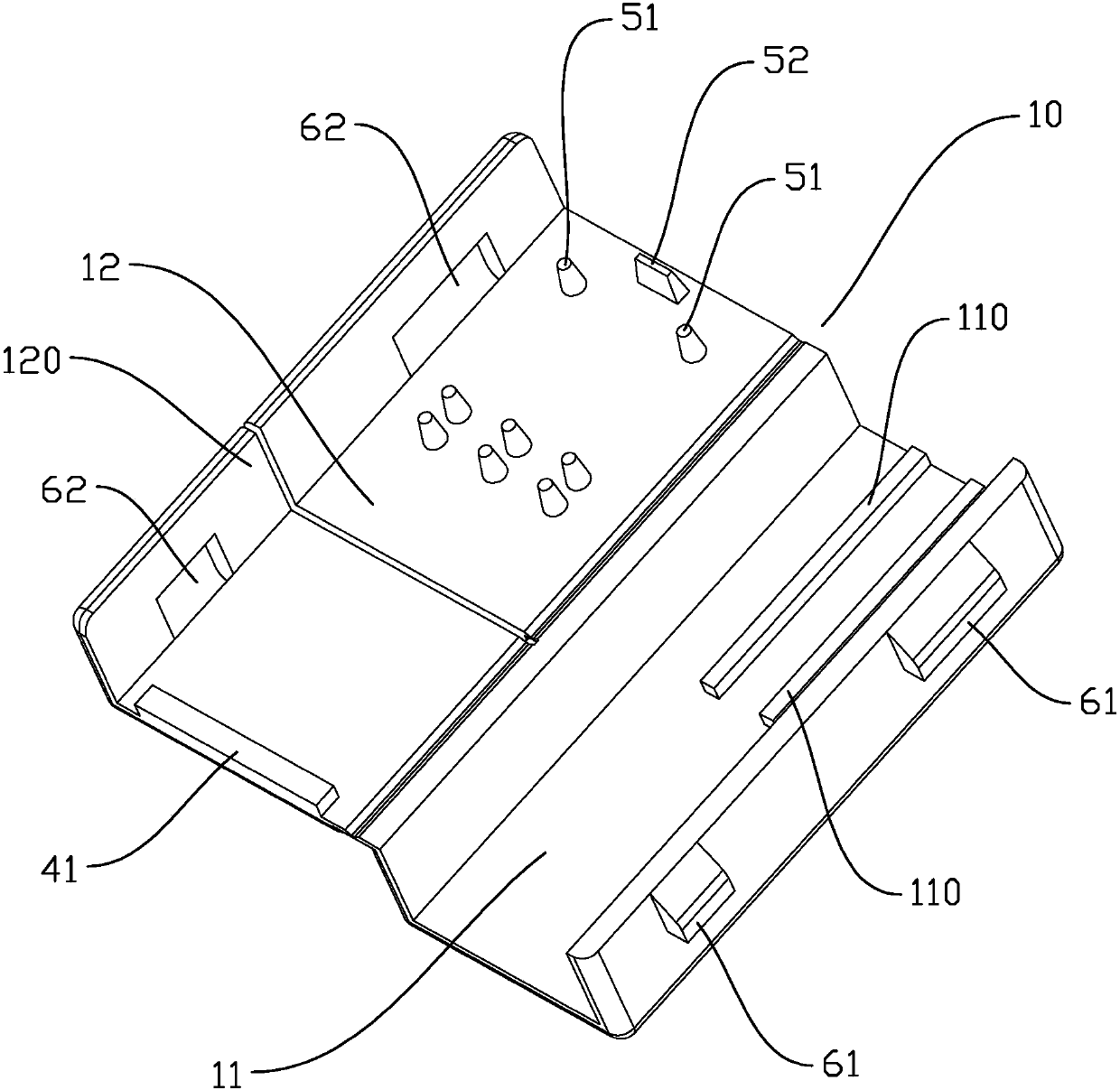

[0029] refer to Figure 1 to Figure 6 , a light strip connector, including a fixed box 10, the fixed box 10 is provided with an open accommodation groove 11, the accommodation groove 11 is an open through groove, that is, the accommodation groove 11 The upper part of the box is open, and the two ends of the accommodating tank 11 are also open. At the same time, the fixed box 10 is also movably provided with a gland 12 that can swing relative to it and can cover the opening of the accommodating tank 11. , that is, the gland 12 can be turned over to cover the opening of the accommodating tank 11. In the present invention, the gland 12 and the fixed box 10 are in an integrated structure, and the gland 12 There is a folded edge between the fixed box 10, and the gland 12 can rotate relative to the fixed box 10 around the folded edge. Of course, the gland 12 and the fixed box 10 are two mutually independent Parts are also possible. At this time, the gland 12 can be hinged on the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com