Brushless signal direct current switch

A DC switch and signal technology, which is applied in the direction of electric switches, electrical components, circuits, etc., can solve the problems of shortening the service life of switches, failure of opening and closing circuits, and easy entry of dust into the housing, so as to prolong the service life and prevent failures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

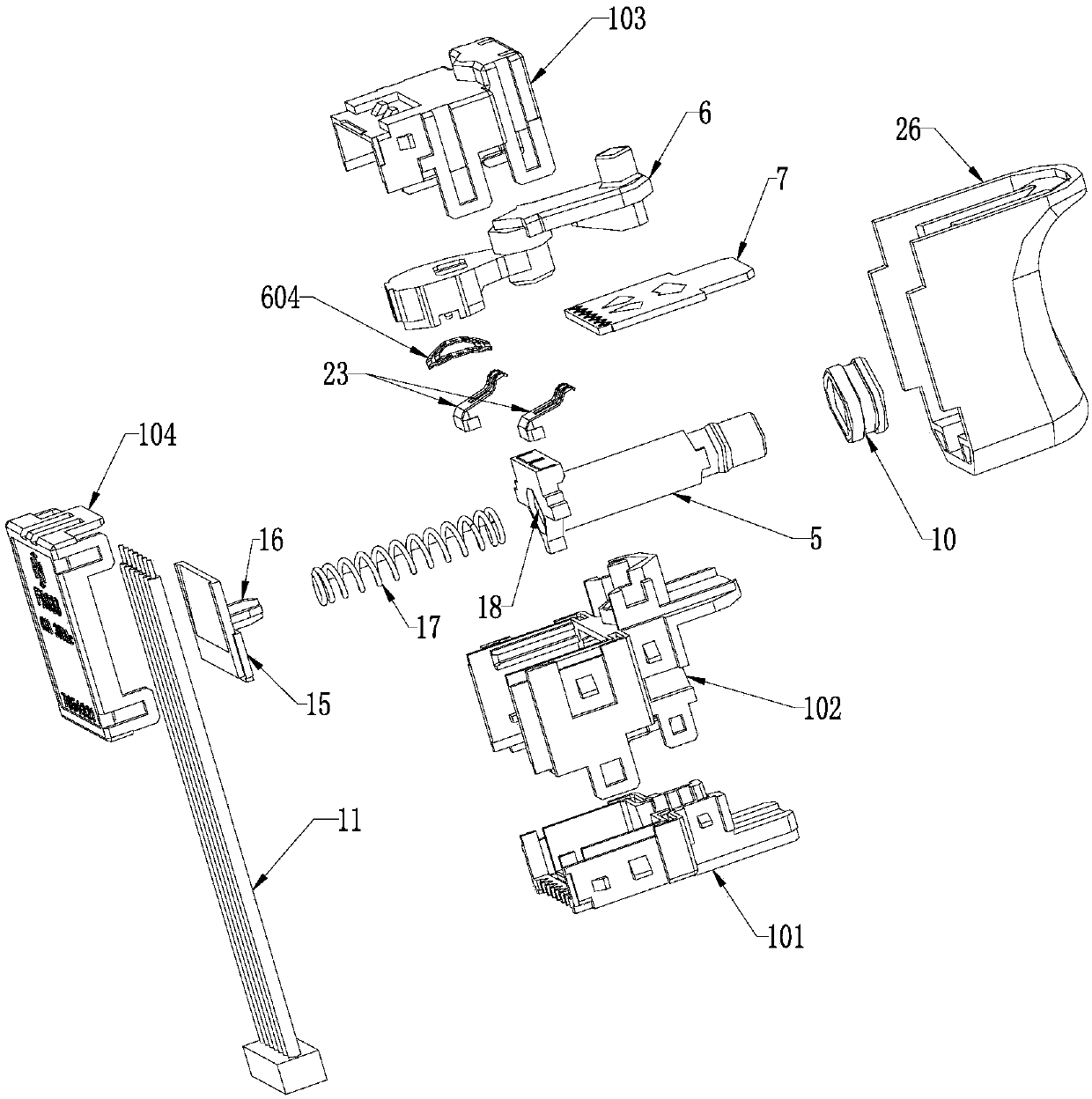

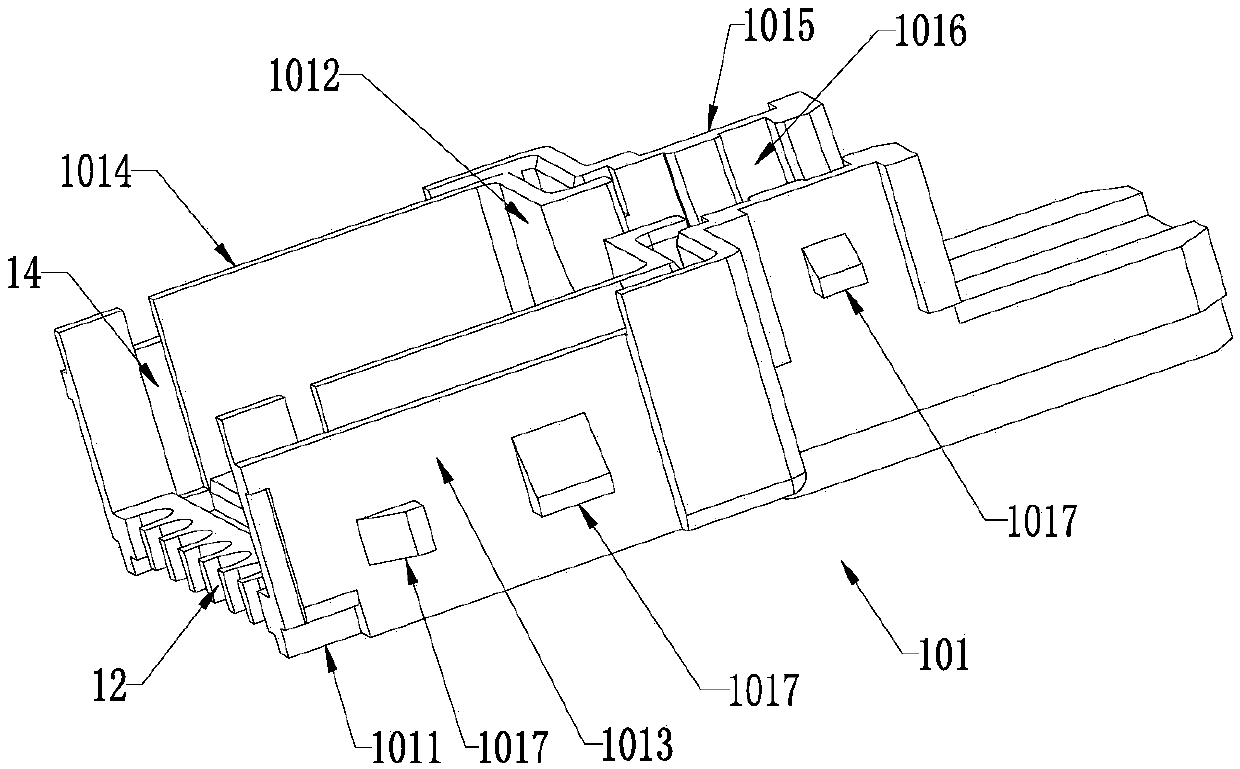

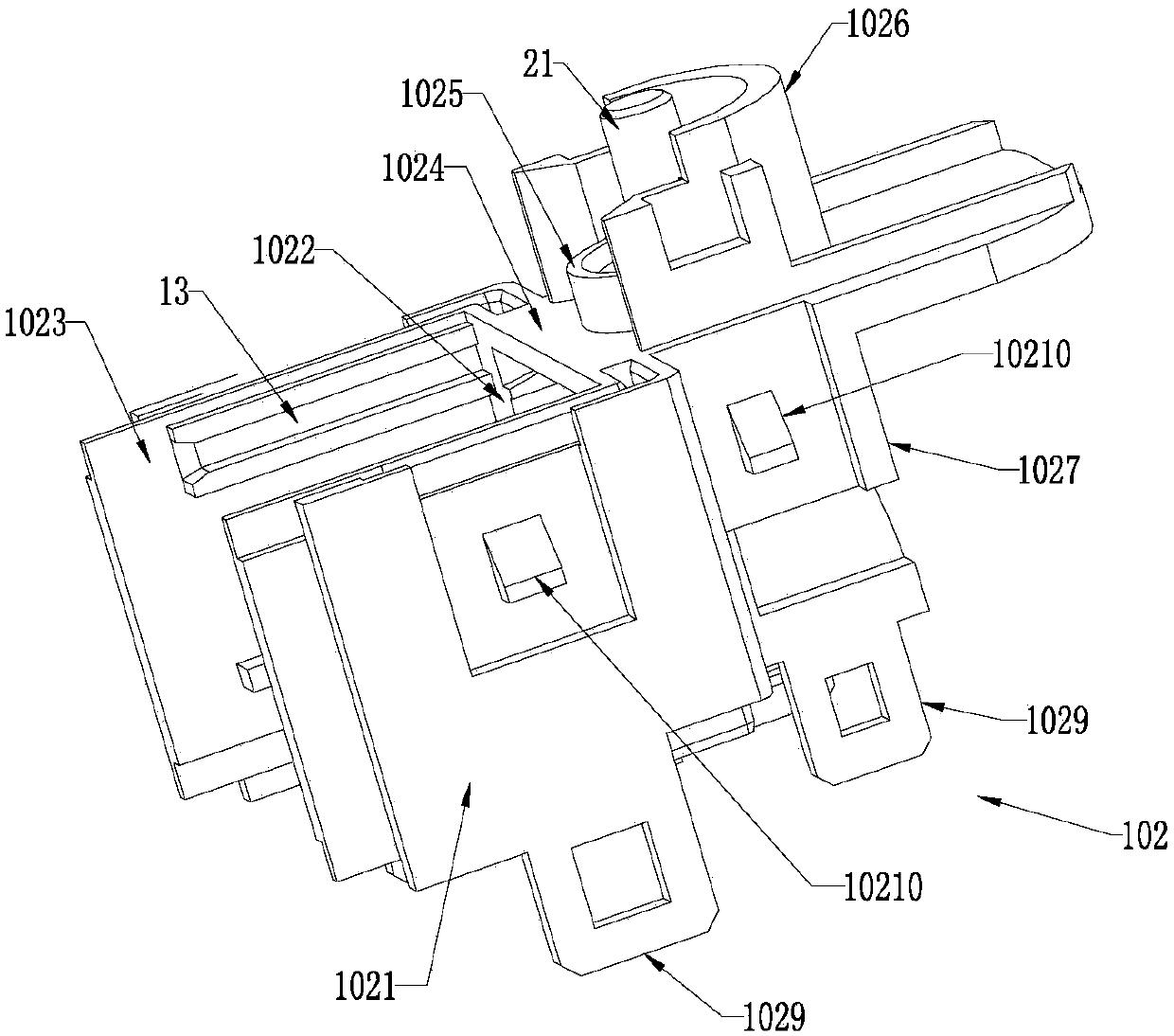

[0032] Such as figure 1 , Figure 7 The shown brushless signal DC switch includes a housing 1, which is provided with a push rod installation hole 2, a handle swing hole 3, and a signal line connection hole 4, and the push rod installation hole 2 is inserted with a The push rod 5, the reversing handle 6 is arranged in the swing hole 3 of the handle, the PCB board 7 is arranged in the housing 1, an opening and closing circuit is arranged on one side of the PCB board, and a reversing circuit is arranged on the other side, and its end The part is provided with connecting terminals, the push rod 5 is used to control the opening and closing of the switching circuit, the reversing handle 6 is used to control the reversing of the reversing circuit, and the PCB board 7 divides the inside of the housing 1 into The reversing chamber 8 and the opening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com