Blanking dust collecting device and blanking dust collecting system

A technology for dust collection and blanking, which is used in the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles. The effect of flying dust and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

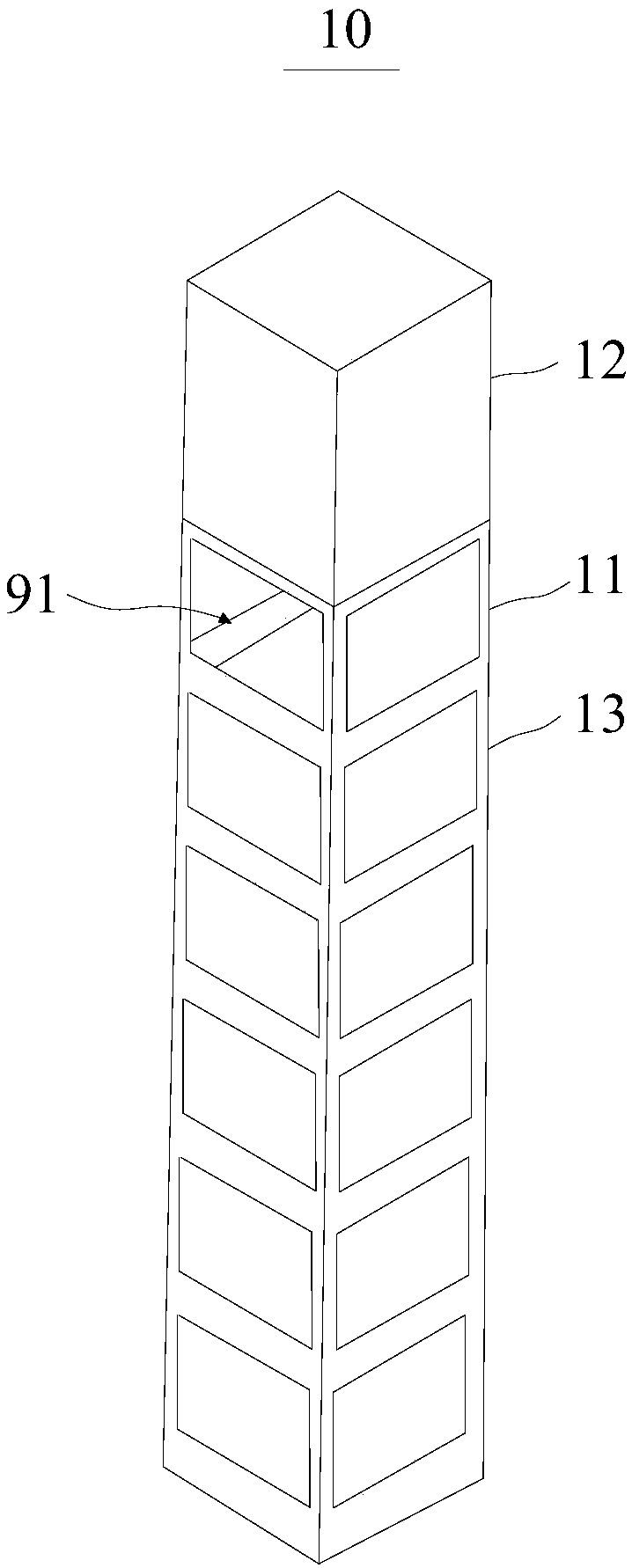

[0059] This embodiment provides a falling dust collection device 10 , which is applied in a sand and gravel plant to perform falling and dust removal on sand and gravel.

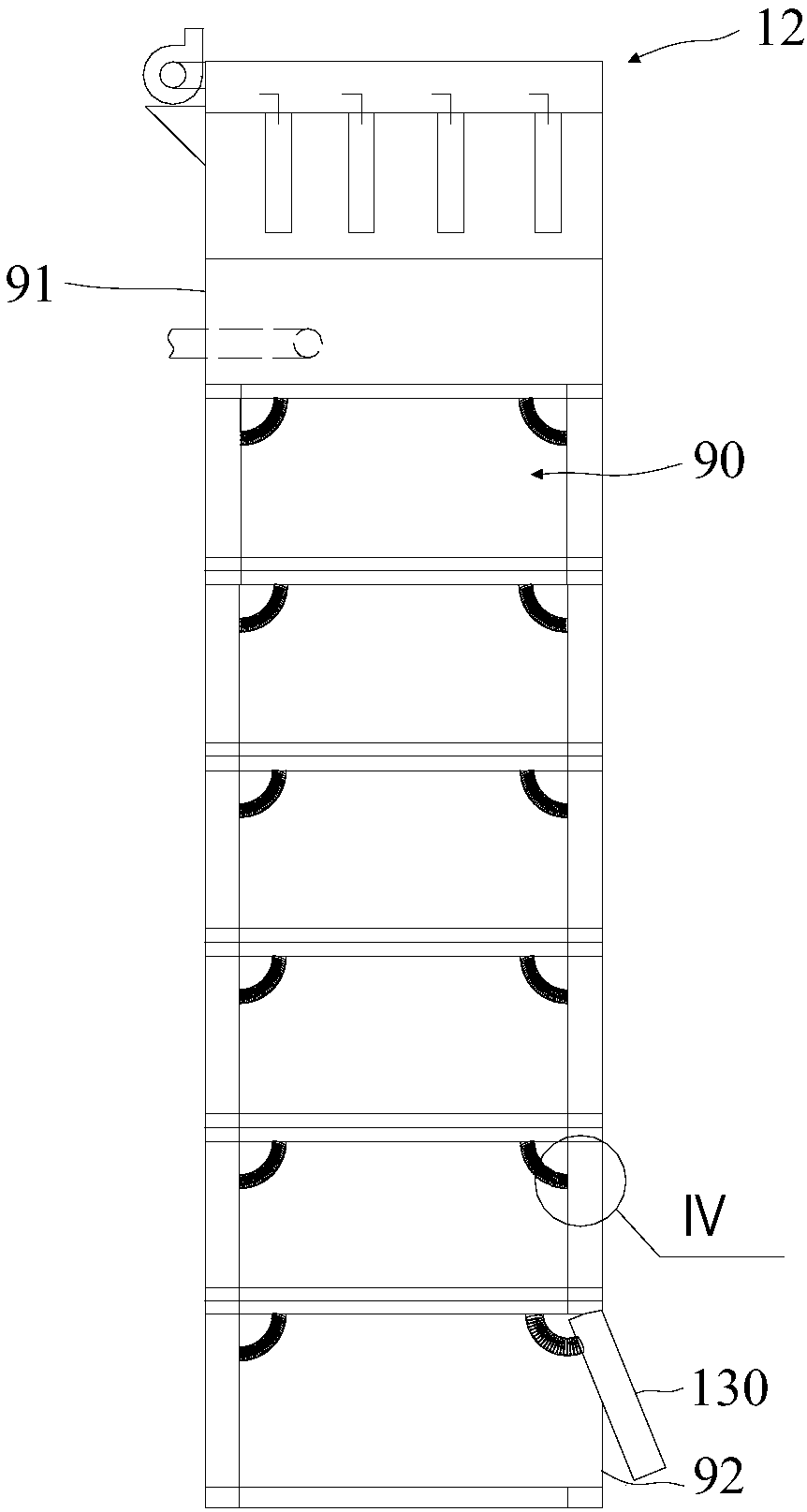

[0060] Please refer to figure 1 and figure 2 , figure 1 The specific structure of the falling dust collection device 10 provided in this embodiment at a first viewing angle is shown. figure 2 Shows the specific structure of the falling dust collection device 10 provided in this embodiment under the second viewing angle

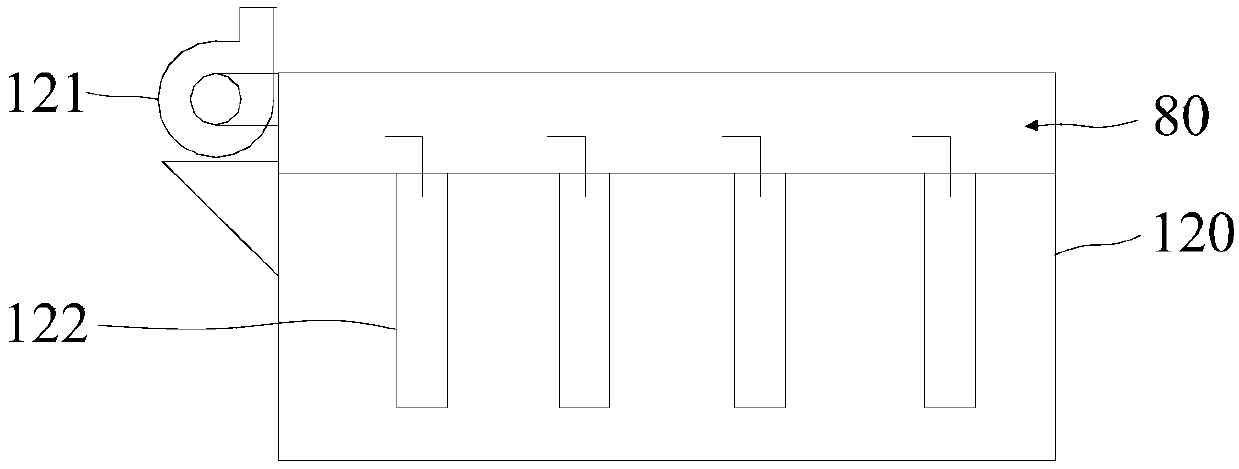

[0061] The falling dust collection device 10 includes a tower base 11 , a dust collector 12 and a movable cover 13 .

[0062] The tower base 11 is erected on the ground. The tower base 11 has opposite first and second ends in the height direction. The first end is far away from the ground. The inner wall of the tower base 11 defines a gravel space 90. The side wall is provided with a sand and gravel feeding port 91, the first end is open and connected to the sand and gravel space 90, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com