Turbulent flow system for reducing ship rolling movement

A technology for ships and rolls, applied in the field of spoiler systems, can solve problems such as increasing ship resistance, achieve the effects of simple and convenient installation, improved safety and speed, and good commercial and military use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

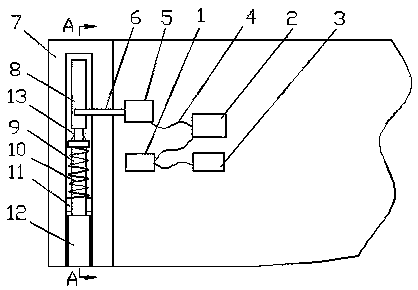

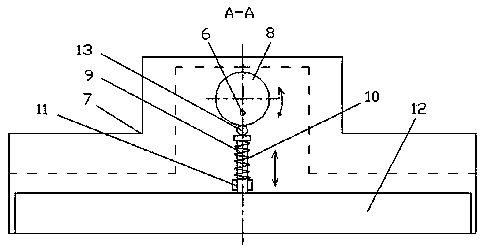

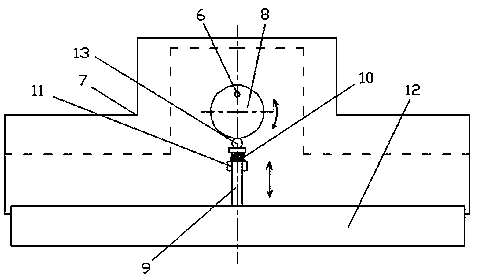

[0016] In order to understand the purpose and technical solution of the present invention more clearly, detailed descriptions will be given below in conjunction with the accompanying drawings.

[0017] figure 1 , 2 A structural schematic diagram of a spoiler system for reducing rolling motion of a ship is shown. In the figure, the spoiler system for reducing the rolling motion of the ship includes a spoiler 12, a protective cover 7, a servo motor 5, a driving mechanism and a control system. The protective cover 7 adopts a groove structure for installing the driving mechanism and the spoiler 12 . The driving mechanism includes an eccentric wheel 8, a push rod 9 and a return spring 10. After the push rod 9 is put on the return spring 10, it passes through the fixed bearing 11 and connects with the spoiler 12. The servo motor 5 is connected to the eccentric wheel 8 through the transmission shaft 6, and the eccentric The wheel 8 rotates and pushes the push rod 9 to reciprocate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com