Glass forming method

A molding method and technology for glass cups, which are used in glass molding, glass remolding, glass manufacturing equipment, etc., can solve the problems of high cost, difficult to shape, and unfavorable hand-holding, and achieve the effect of high automation control and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

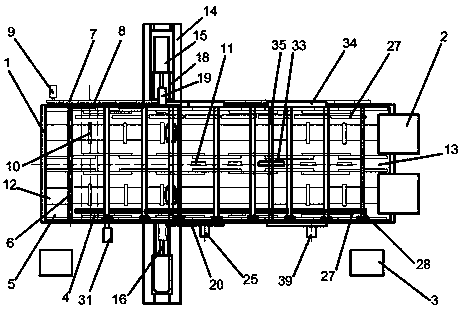

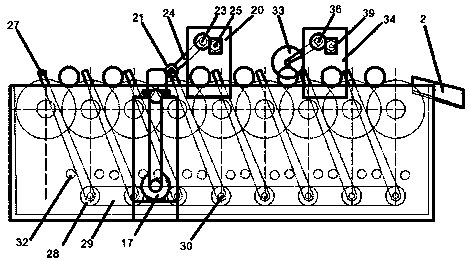

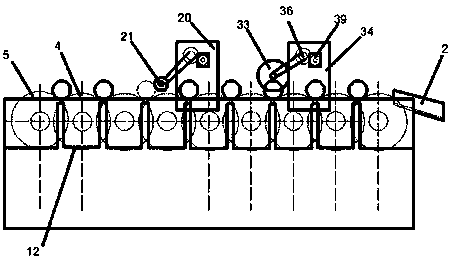

[0034] Such as Figure 1 to Figure 5 As shown, a glass forming method, which uses a glass forming device, the glass forming device includes a frame 1, a rotating drive assembly, a heating assembly, a forming assembly, a cutting assembly, a toggle assembly, and a finished product groove 2 and the controller 3, the frame 1 is an opening on the upper surface, and the rotating drive assembly, the heating assembly and the toggle assembly are installed inside the frame 1, and the two sides of the middle position in the left and right direction and the upper part of the frame 1 are installed. As for the forming component, the cutting component is installed on the upper right part of the middle of the frame, and the finished product groove 2 is installed on the right end face.

[0035] Wherein, there are 9 groups of the rotating drive assembly, that is, there are 9 stations, including the inner friction wheel 4, the outer friction wheel 5, the first rotating shaft 6, the first chain w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com