Method for reinforcing chamfering formworks

A formwork and chamfering technology, which is applied in the joints of formwork/formwork/work frame, the preparation of building components on site, construction, etc., can solve the problem of large formwork joints at chamfers and insufficient formwork rigidity at chamfers, etc. problems, to achieve the effect of small joints, shortened construction period, and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

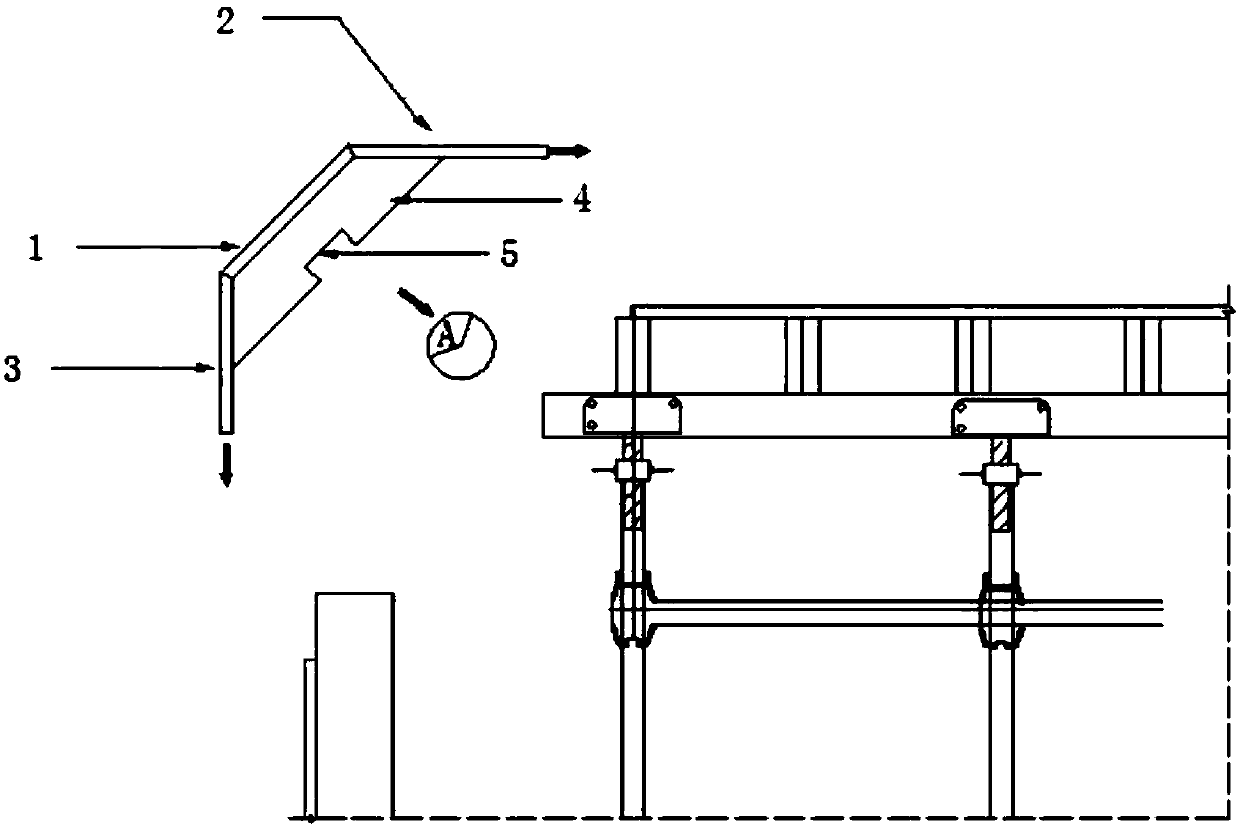

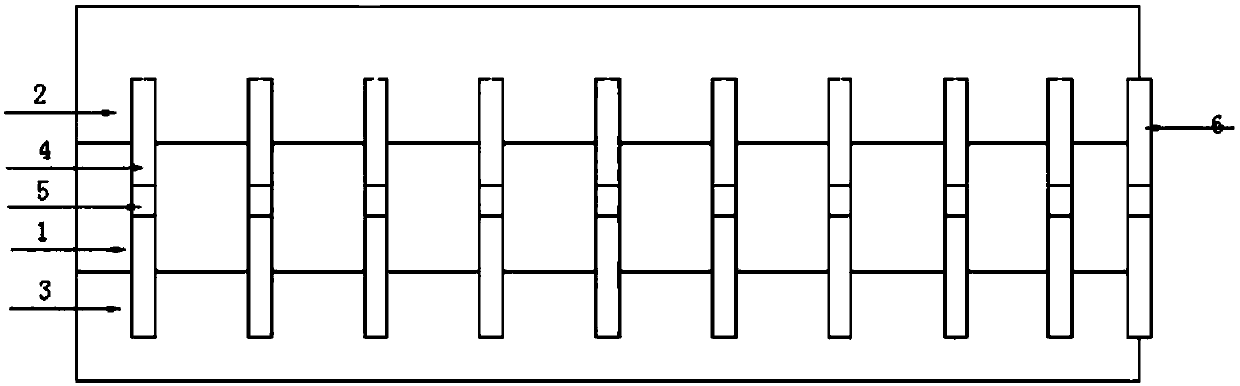

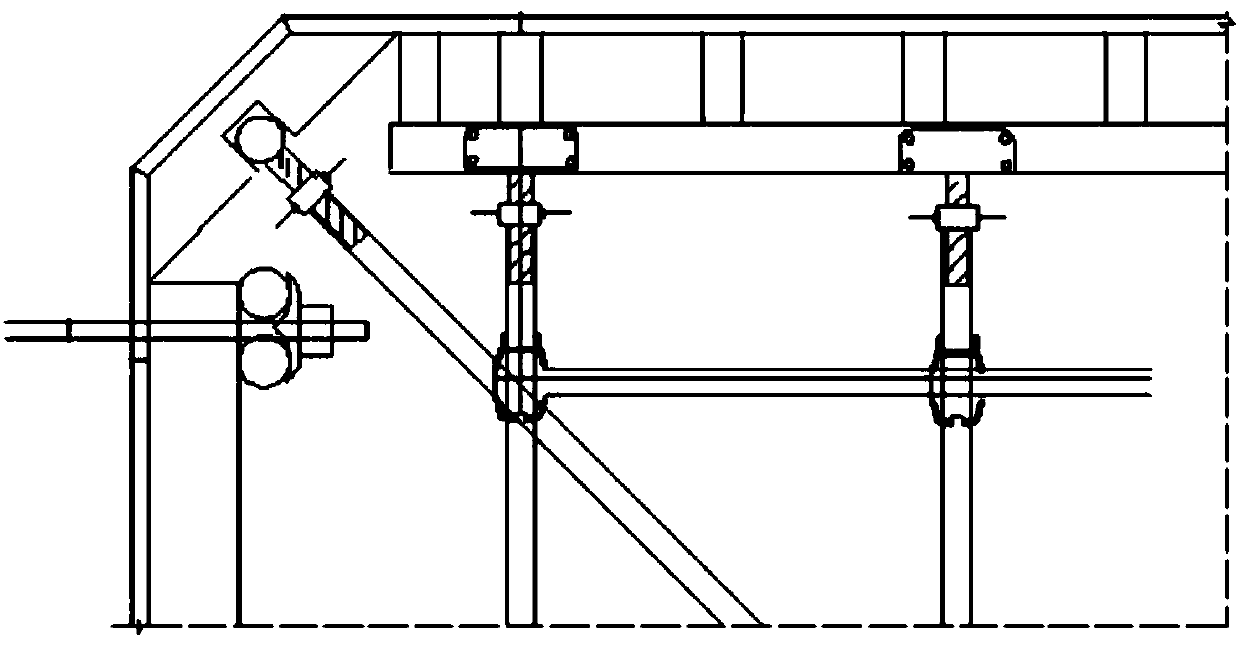

[0031] exist figure 1 , figure 2 and image 3 Among them, a method for reinforcing a chamfered formwork in this embodiment, the chamfered formwork includes a web formwork 1, an upper flange formwork 2 and a lower flange formwork 3, and the above-mentioned web formwork 1 is fixedly connected to the stiffener square wood 4 On the upper surface, both sides of the stiffening rib square wood 4 are fixedly connected with the upper flange formwork 2 and the lower flange formwork 3 in turn, and the middle part of the lower surface of the stiffening rib square wood 4 is provided with a steel pipe limiting groove 5, One end of the shaped and chamfered wood formwork is reserved, and the other end is reserved for the square wood butt support bar 6. According to the actual situation on site, taking the side length of 150mm and the chamfer of 45° as an example, the length of the web formwork 1 is 212mm , the length X of the upper flange template 2 is 1830mm, the length Y of the lower fla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Side length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com