Multifunctional flange

A multi-functional, flanged technology, applied in flange connection, anti-corrosion coating, pipe/pipe joint/pipe fitting, etc., can solve the problems of waste of material and manpower, leakage of pipeline connection, etc., and achieve good fixing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

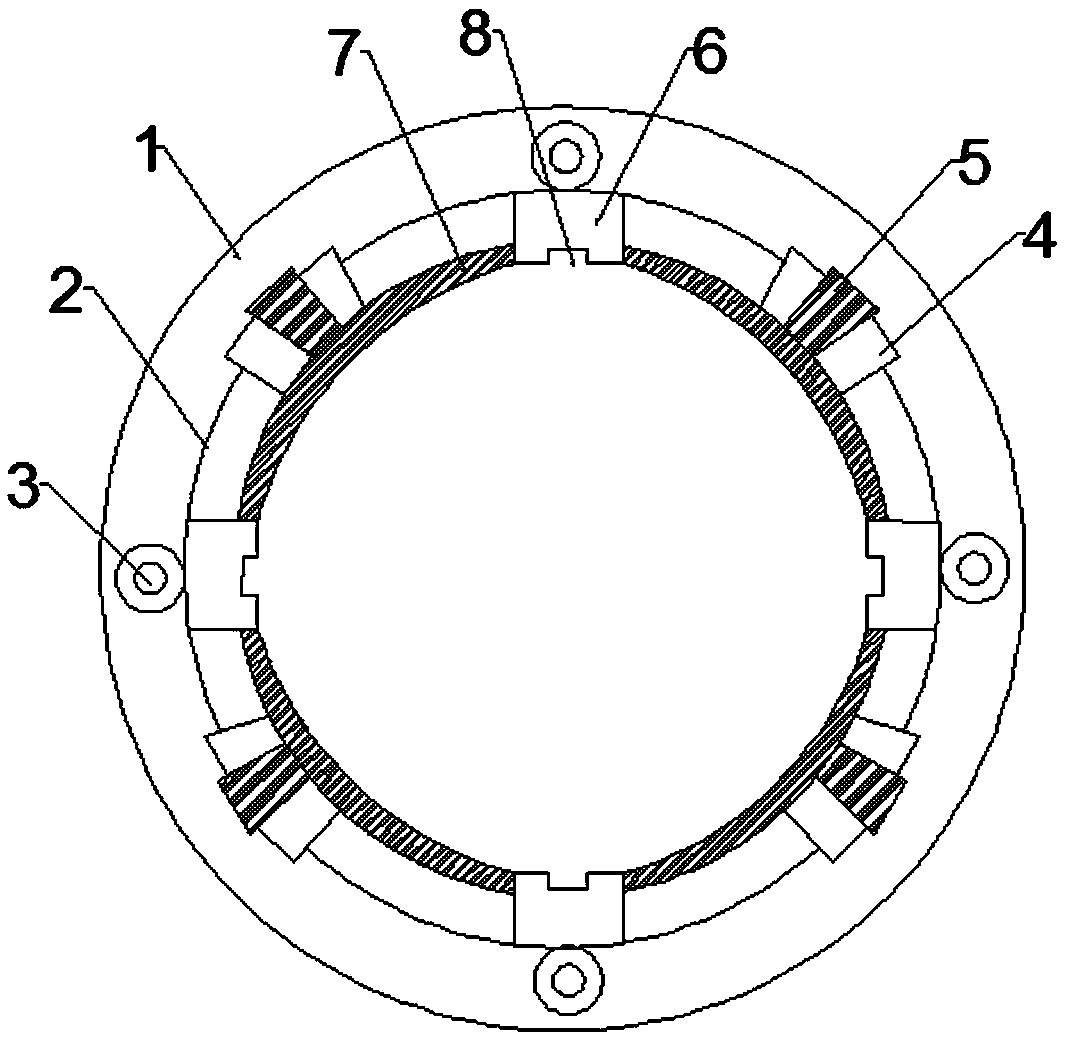

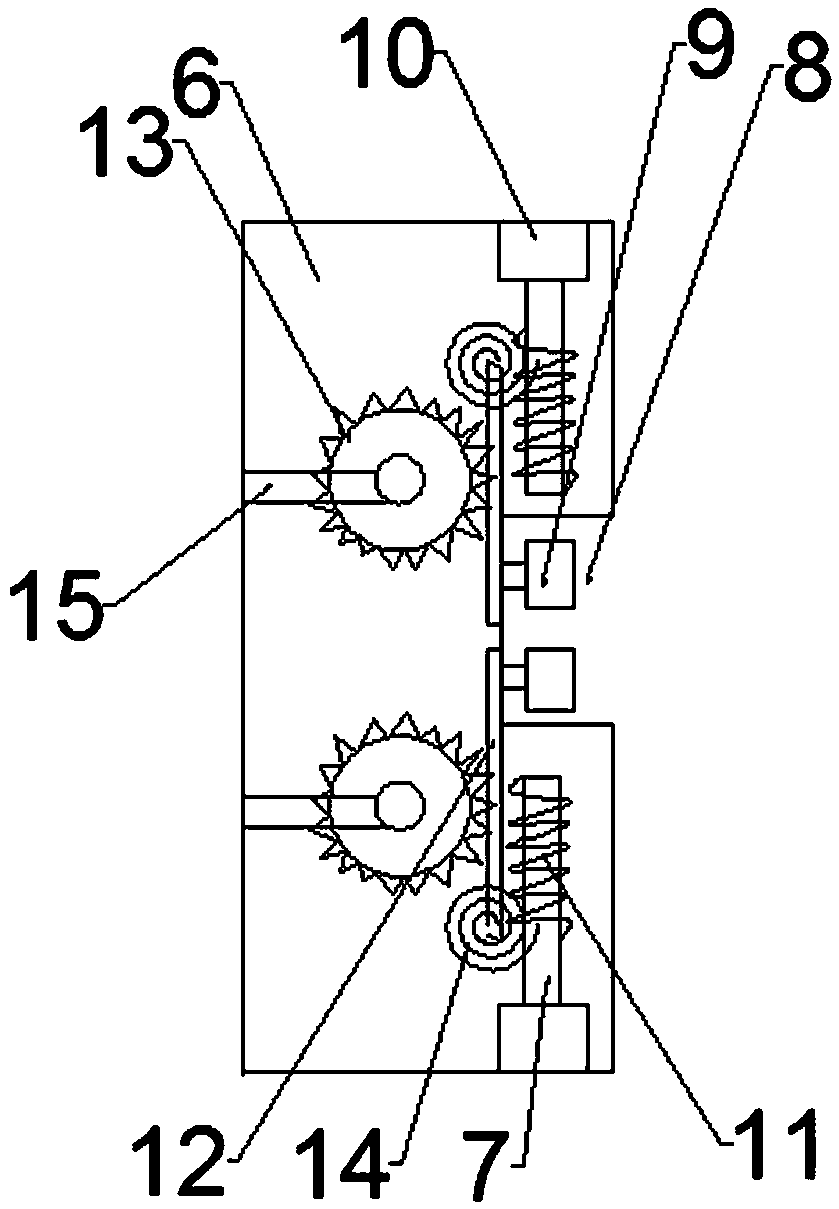

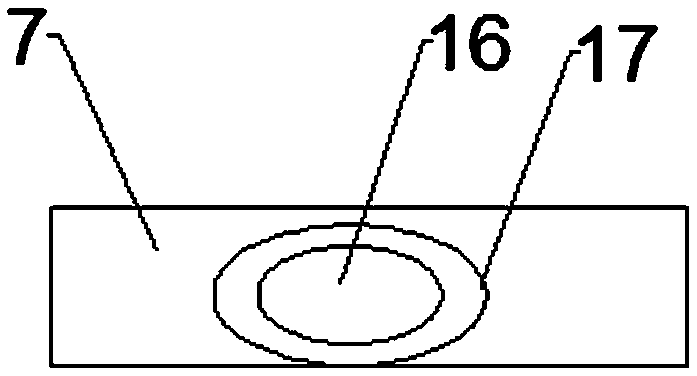

[0037] see Figure 1 to Figure 4 , the present invention provides a technical solution: a multifunctional flange, including a body 1 and a gasket 2 installed on the body 1, four fixing rings 3 are arranged between the gasket 2 and the body 1, the fixing rings 3 A rotating ring 18 is arranged inside, and four control blocks 6 are fixed on the inward position of the spacer 2. The control blocks 6 correspond to the positions of the fixed ring 3 one by one. Two moving blocks 9 are arranged on the control block 6, and the adjacent control blocks 6 All are fixed by the connecting ring 7, the connecting ring 7 passes through the side of the control block 6 and stretches into the control block 6, the connecting ring 7 extending into the control block 6 is provided with a thread 11, and the control block 6 is provided with two pairs of The rack 12 and the gear 13, the moving block 9 extends into the adjusting block 6 through the transverse groove on the adjusting block 6 and is fixed w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com