Noise insulation dustproofing motor end cover

A motor end cover, dustproof technology, applied in the field of motor parts, can solve the problems of the motor end cover without sound insulation, serious noise pollution in the workshop, poor dustproof performance, etc., to achieve simple and reasonable structure, improve dustproof performance, improve The effect of the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

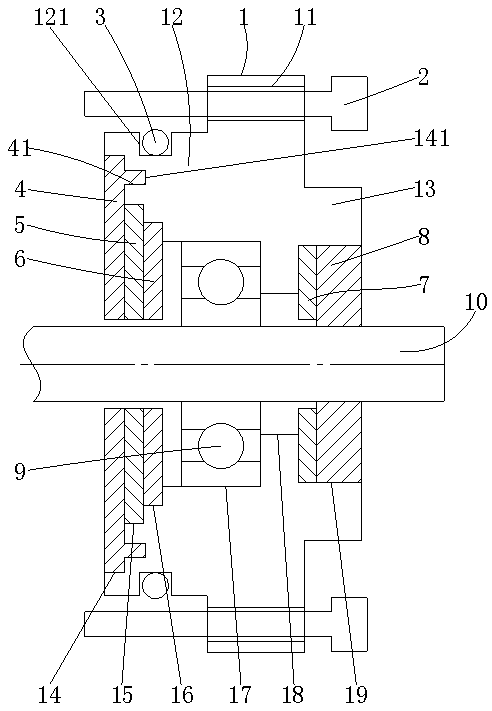

[0010] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

[0011] Such as figure 1 As shown, a noise-insulating and dust-proof motor end cover includes an end cover body 1, a plurality of through holes 11 are evenly distributed on the outer edge of the end cover body 1, and mounting screws 2 are inserted in the through holes 11 to facilitate the connection with the motor. Shell connection, the left and right end faces of the end cover body 1 are respectively provided with a first boss 12 and a second boss 13, the outer wall of the first boss 12 is provided with a sealing groove 121 and the sealing groove 121 is provided with There is a sealing ring 3, and when connected with the motor casing, the first boss 12 is matched with the inner hole of the motor casing, and the sealing ring 3 can effectively improve the sealing performance of the motor.

[0012] The e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com