A method for pulling through the core of an extreme short-axis shoulder-pole beam motor

A technology of pole beam and short shaft is applied in the field of large motor installation and maintenance, which can solve the problems of lack of available space and small motor space in the workshop.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

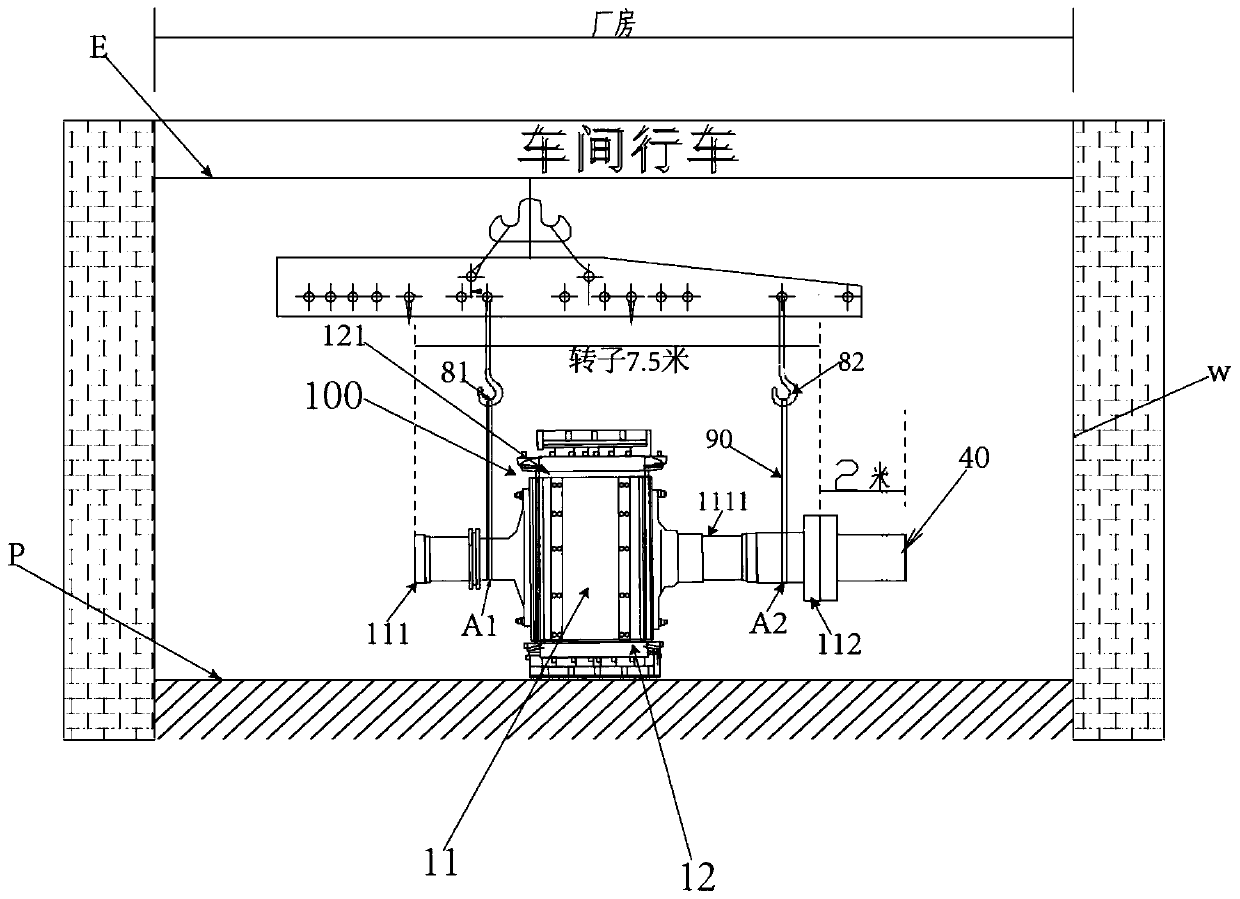

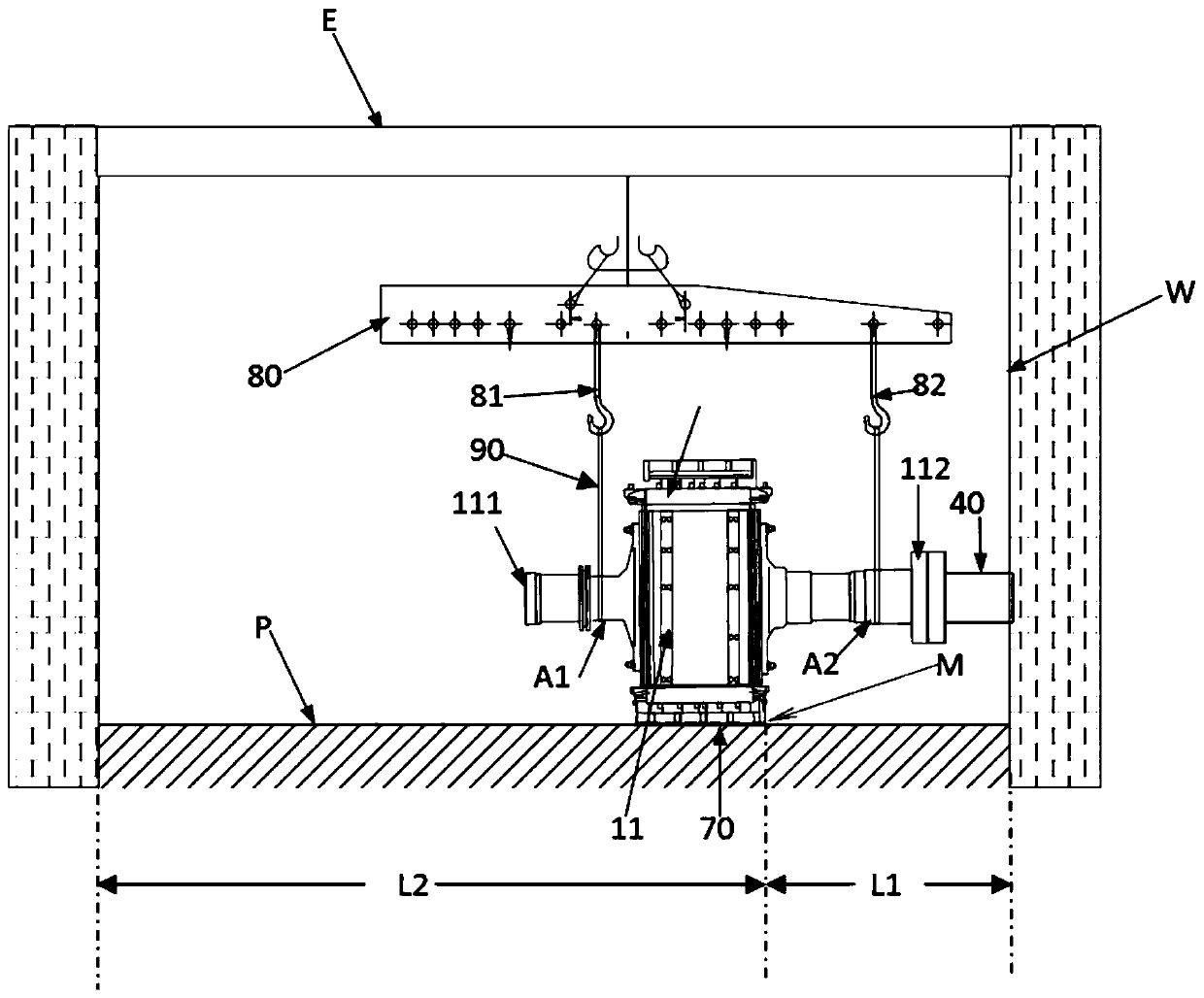

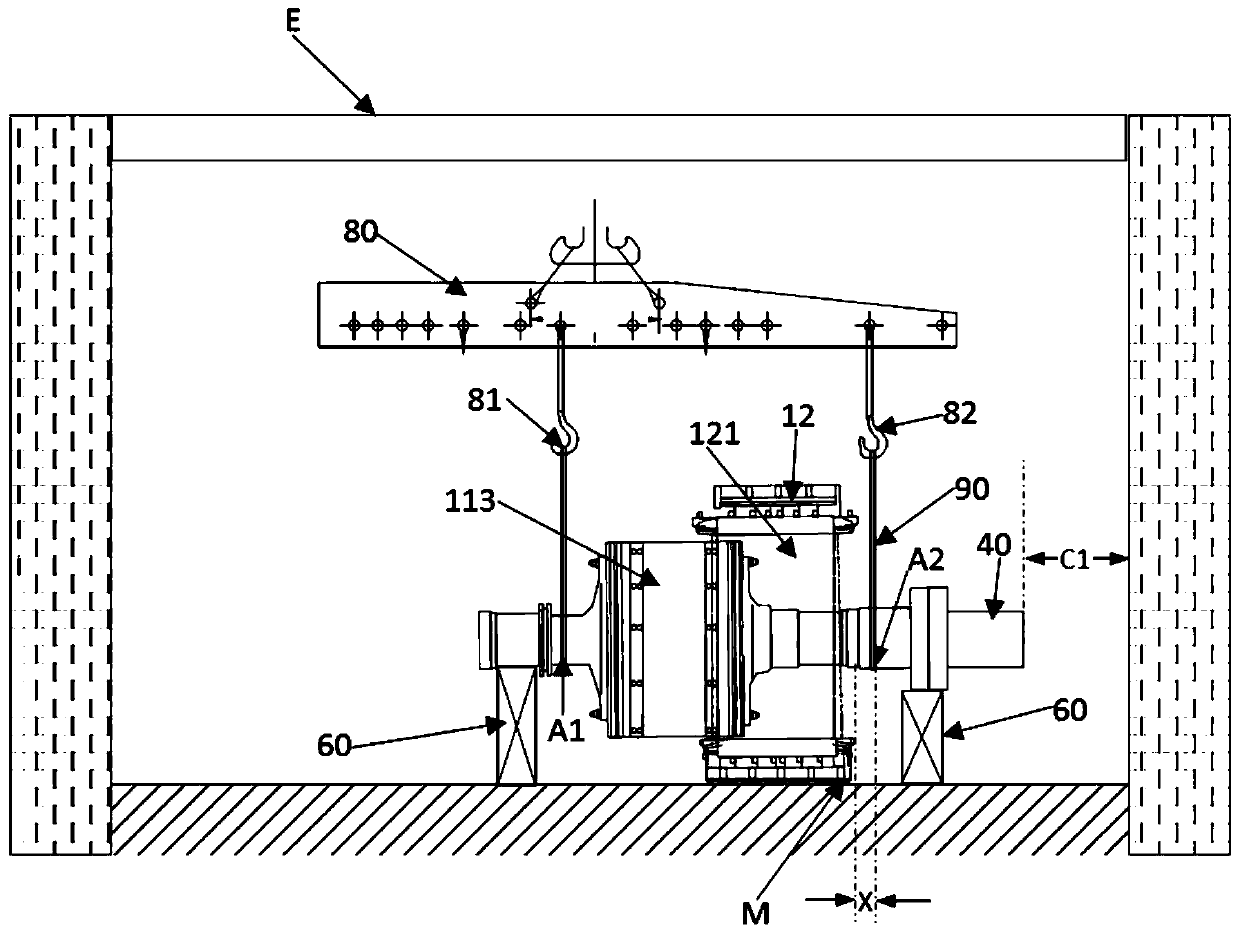

[0060] A preferred embodiment of the present invention, the method for pulling through the core of the extreme short-axis pole beam motor, see Figure 1-Figure 6 , which basically includes the following steps:

[0061] (1) Short shaft installation preparation: insert a buffer isolation plate (not shown) in the inner hole 121 of the stator 12 of the motor 100, so that the buffer isolation plate is interposed between the stator 12 and the rotor 11, preventing the rotor 11 from The inner hole 121 of the stator 12 is in direct contact with the hole wall; the two hoisting ropes 90 are respectively sleeved on the two hoisting points of the rotating shaft 1111 of the rotor 11, one hoisting point A1 is close to the motor collector ring 111, and the other hoisting point A2 is close to the rotor. The coupling 112 side is defined as the coupling side lifting point; the rotor 11 and stator 12 are integrally lifted to a core-pulling site P by using the workshop crane pole beam.

[0062] S...

Embodiment 2

[0080] Embodiment 2 is completely consistent with Embodiment 1 in the core pulling step. The only difference is that the short shaft installation preparation, short shaft installation, limit point selection, and overall lifting to the limit point in Embodiment 1 are changed to "limit point selection, overall lifting to the limit point, and short shaft installation" steps. This is because the selection of the limit point does not necessarily have to be carried out after the installation of the short shaft is completed. After the short shaft 40 of a certain specification and length is selected, it can be based on the actual situation of the core-pulling site. Just find the limit point M, then directly lift the motor 100 as a whole to the position of the limit point M, then connect the short shaft 40 to the shaft coupling 112 of the rotating shaft, and then perform the same first stage, Operation of the second stage and third stage core pulling steps. It is understandable that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com