Manufacturing method of long and thin seamless tubes

A seamless tube and thin technology, which is applied in the field of pipe fittings manufacturing method, can solve the problems of low production efficiency and inability to continuously produce tube blanks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

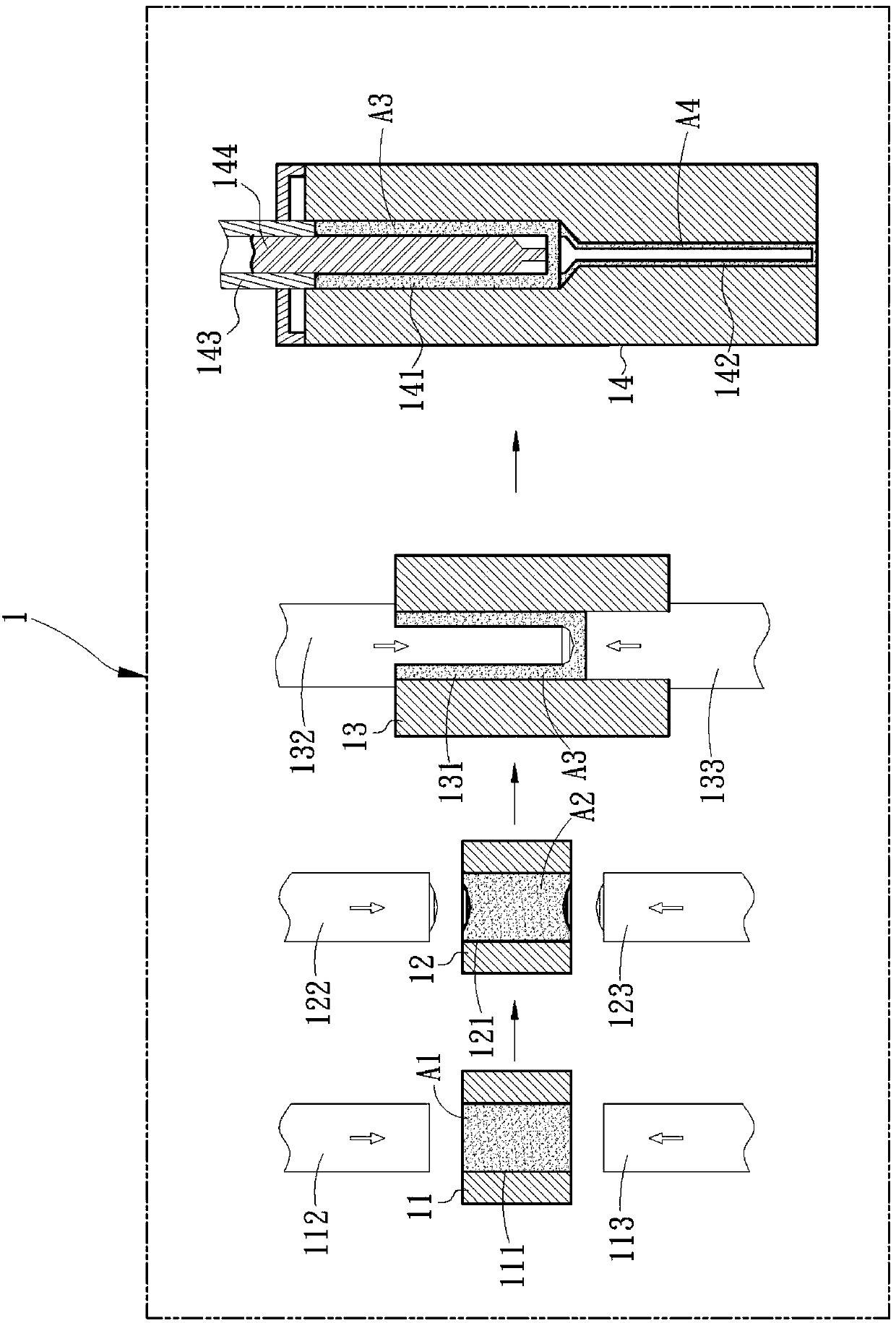

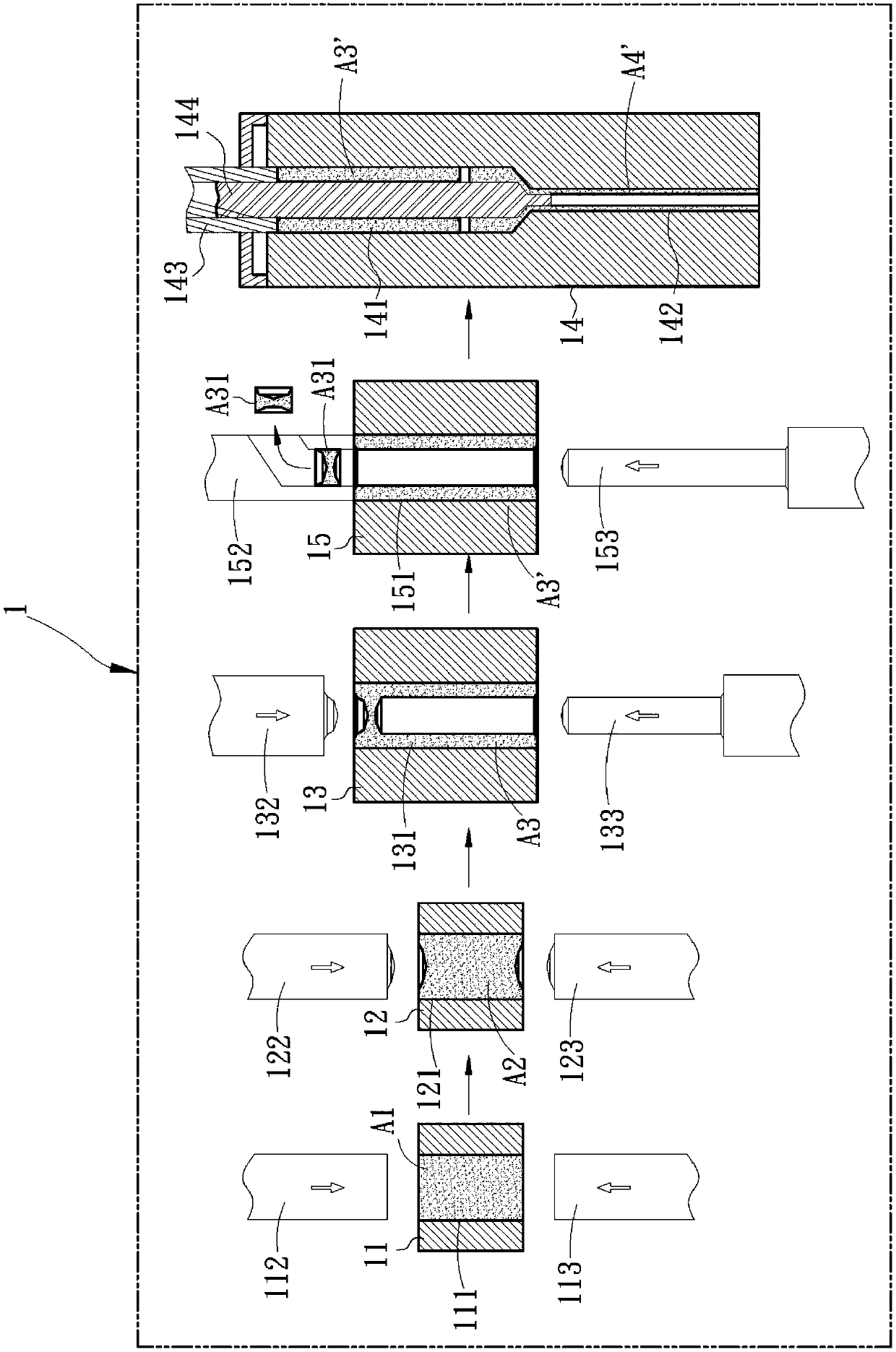

[0050] First of all, it is explained that the present invention is a method for making long, thin and thin seamless pipes, and in the method of the present invention, it is necessary to cooperate with a pipe forming machine to complete all the processes, and in a preferred embodiment of the present invention , the pipe forming machine 1 includes a first mold 11, a second mold 12, a third mold 13 and a fourth mold 14, wherein the first mold 11 has a first through portion 111, and the first The through portion 111 accommodates a tube blank (not shown in the figure), and in this embodiment, the aforementioned tube blank is cut from a strip-shaped solid material of a disk element, but the tube blank The cutting part is often uneven, so when the tube blank is placed into the first through portion 111 of the first mold 11, the tube blank in the first through portion 111 often protrudes from the outside. In this regard, a first upper punch 112 and a first lower punch 113 are provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com