Frame automatic locking device for forming machine

An automatic locking and molding machine technology, applied in the direction of ceramic molding machines, supply devices, auxiliary molding equipment, etc., can solve the problems of troublesome and unsafe locking and separation processes, and achieve the goal of eliminating potential safety hazards, ensuring accurate positioning, and accurate positioning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The frame automatic locking device for forming machine of the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments:

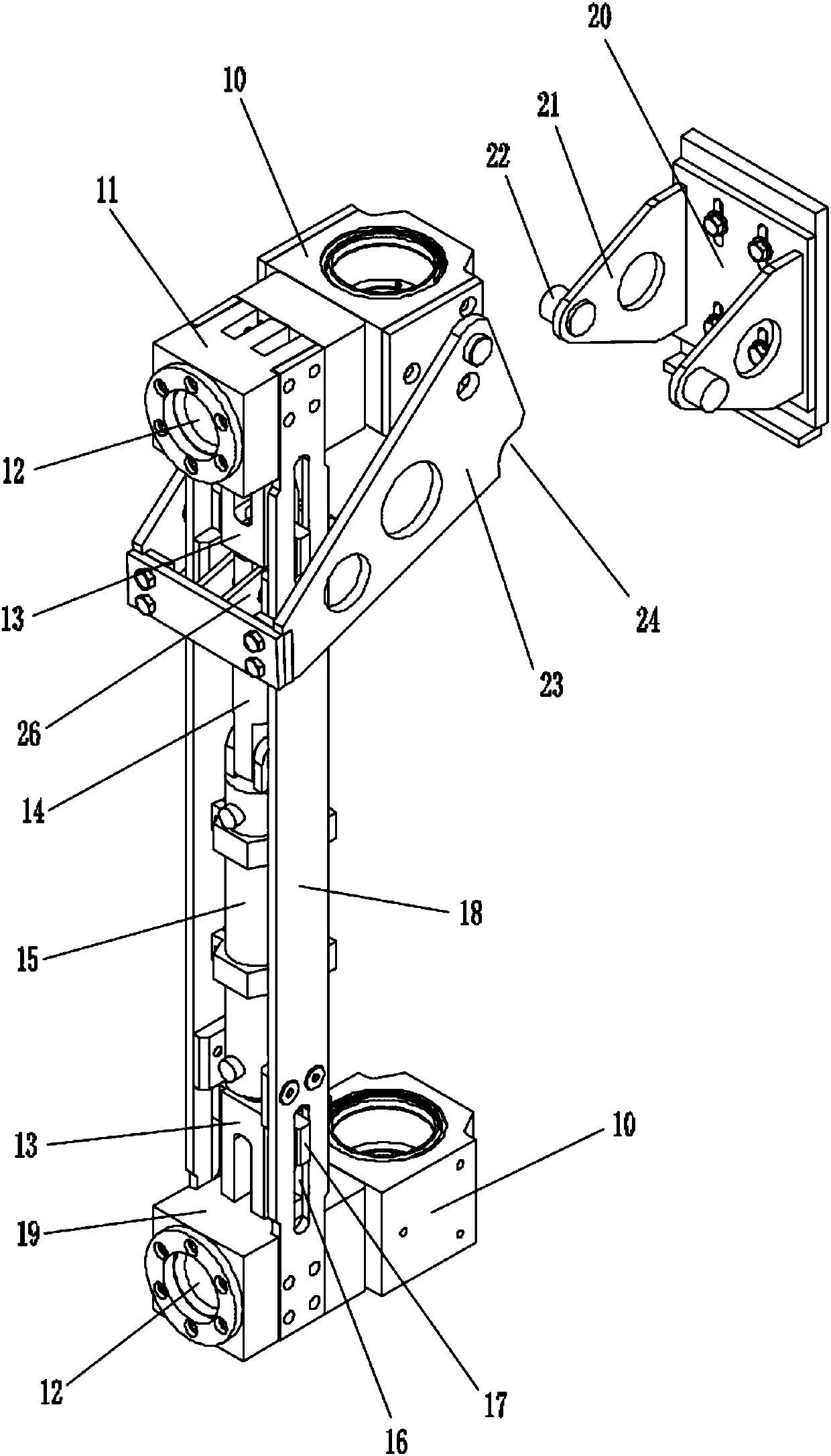

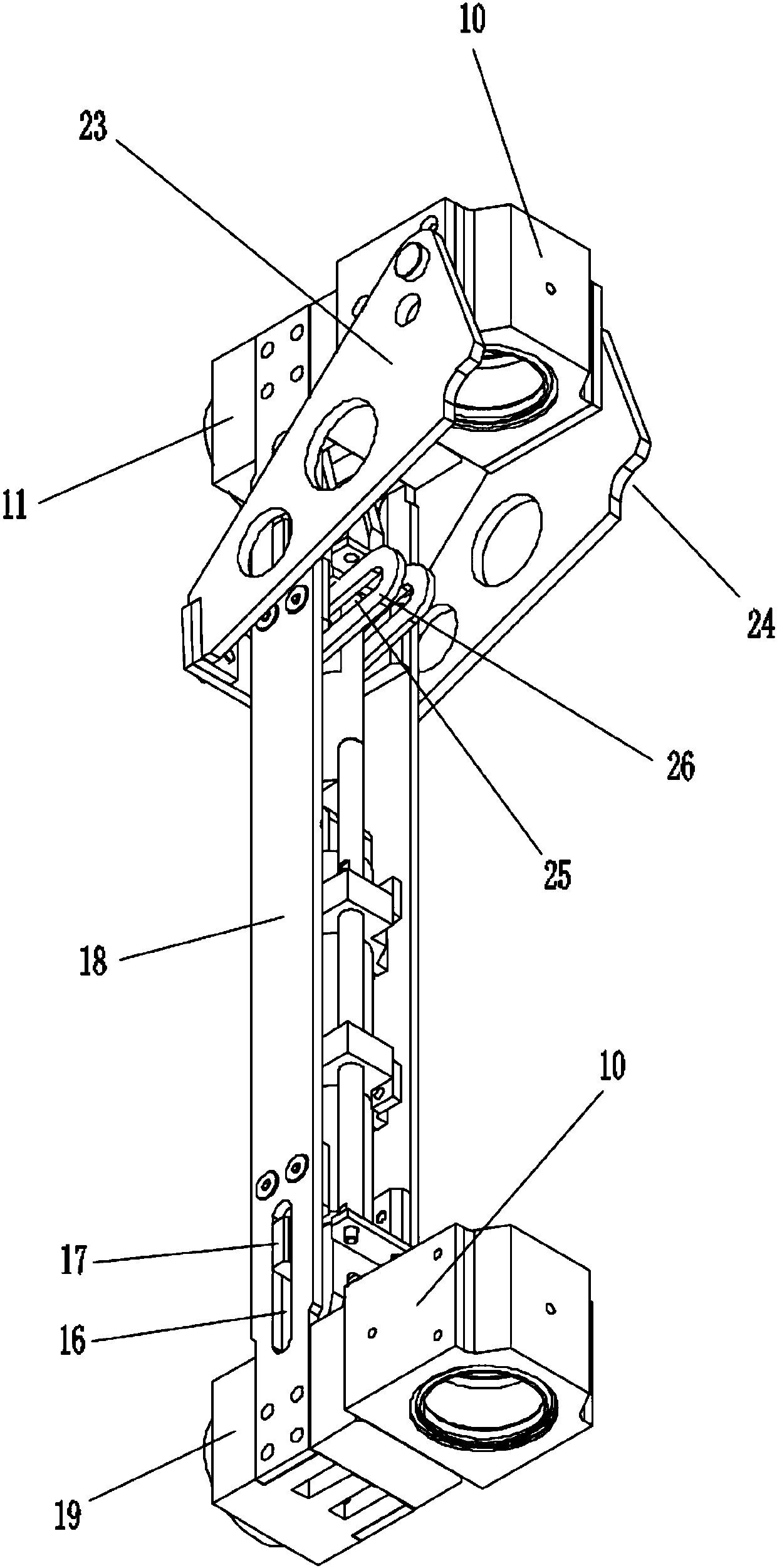

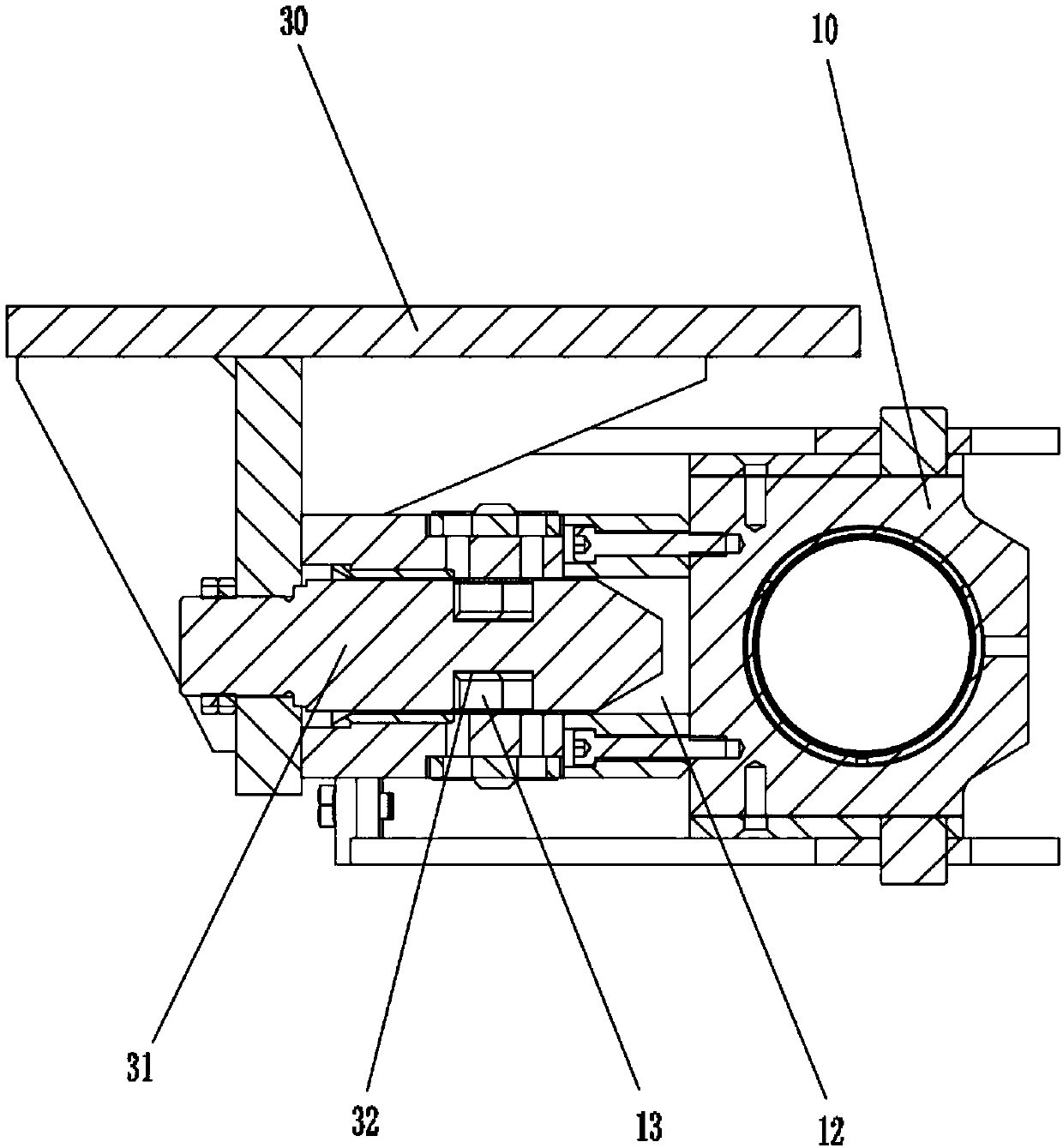

[0020] Such as figure 1 , figure 2 and image 3 As shown, in this specific embodiment, the frame automatic locking device for molding machine of the present invention includes a guide sleeve 10 for being installed on the guide column of the intermediate frame forming part, and also includes an upper plug block 11, a lower plug block 19, A plug 13 for inserting into the cavity of the upper plug block 11 and the lower plug block 19 and a driving device 15 for controlling the expansion and contraction of the plug 13 . Drive unit 15 specifically adopts oil cylinder (certainly also can adopt air cylinder), and oil cylinder is electrically connected with controller by electromagnetic valve, and its piston rod 14 is connected with plug 13, and the elongation and shortening of piston rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com