Composite material main and auxiliary spring assembly and suspension

A composite material, main and auxiliary spring technology, used in suspension, elastic suspension, transportation and packaging, etc., can solve the problems of large mass, short fatigue life, smoothness and life of leaf springs, and achieve strong corrosion resistance. , the effect of stiffness reduction, dynamic and braking performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

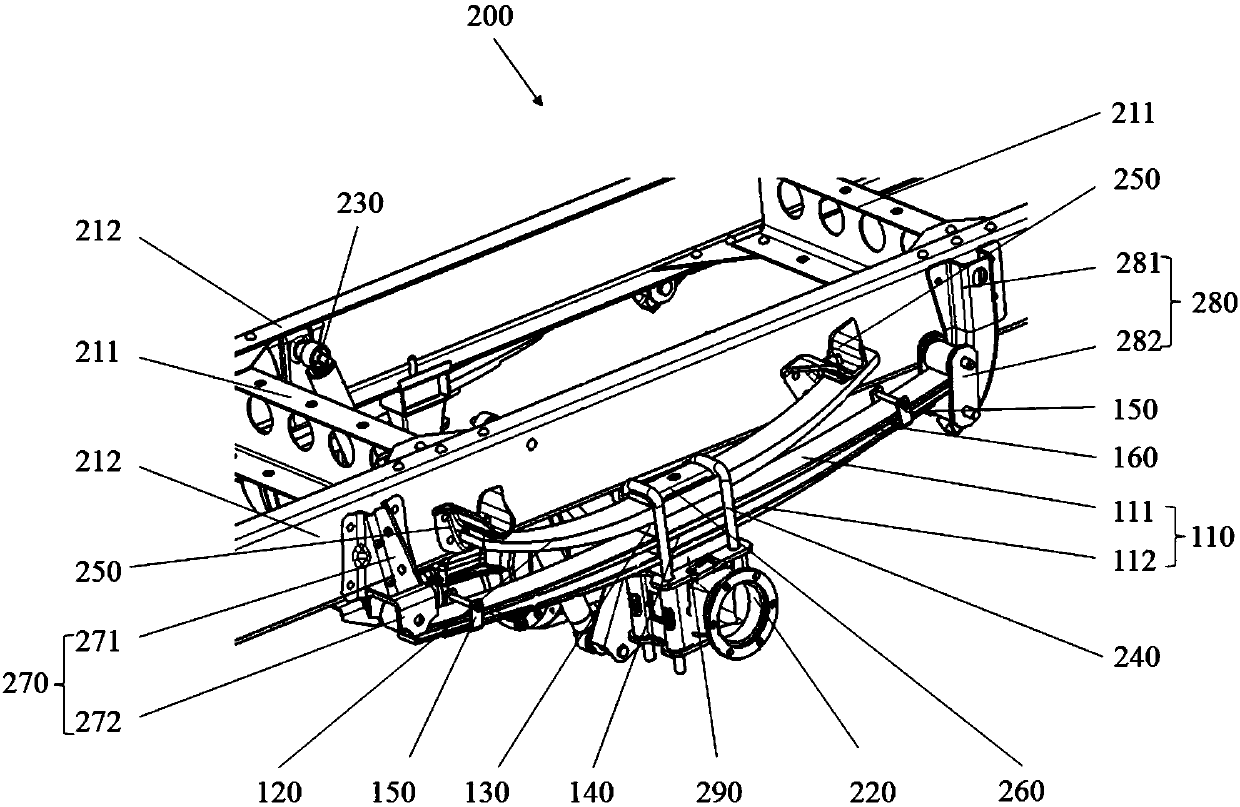

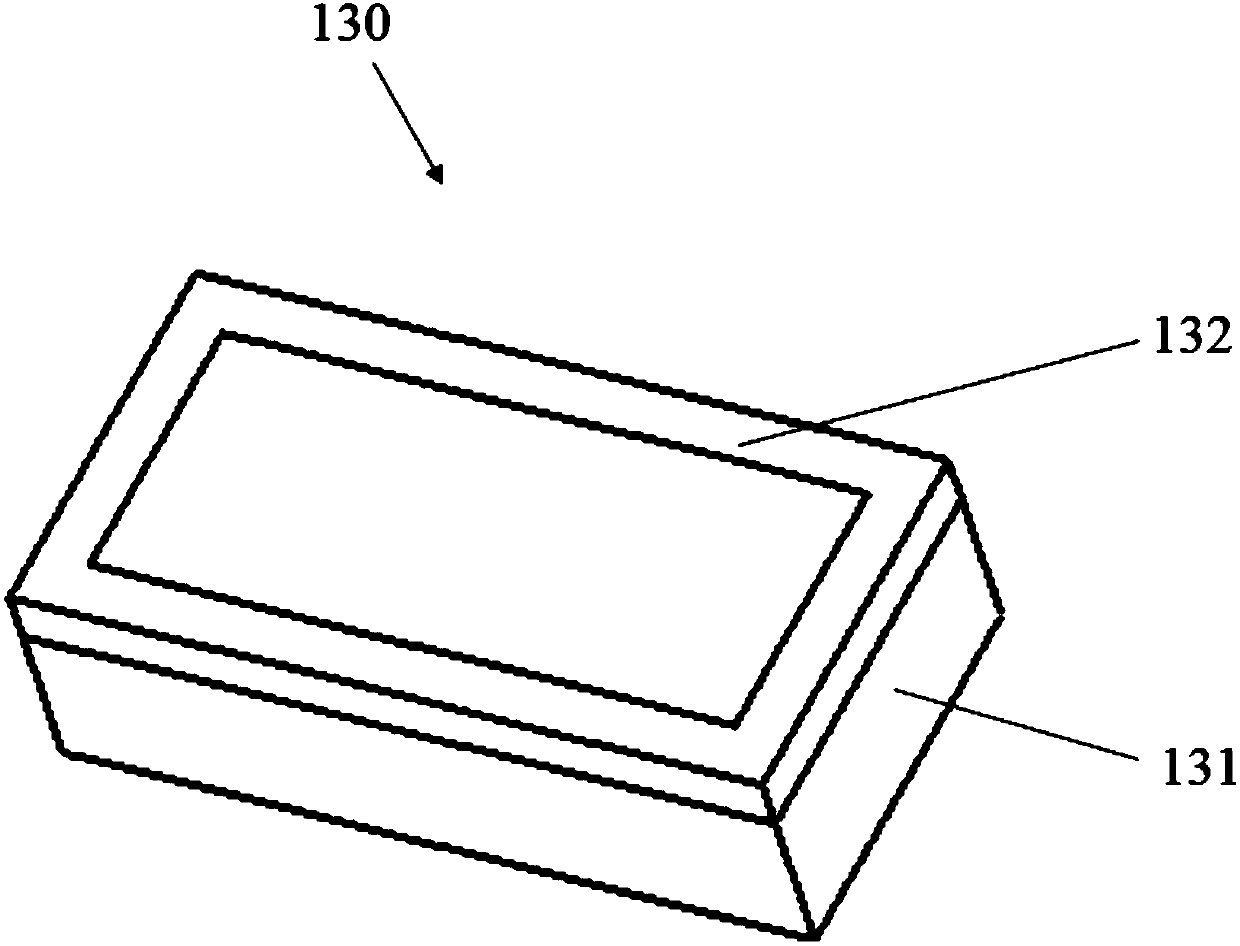

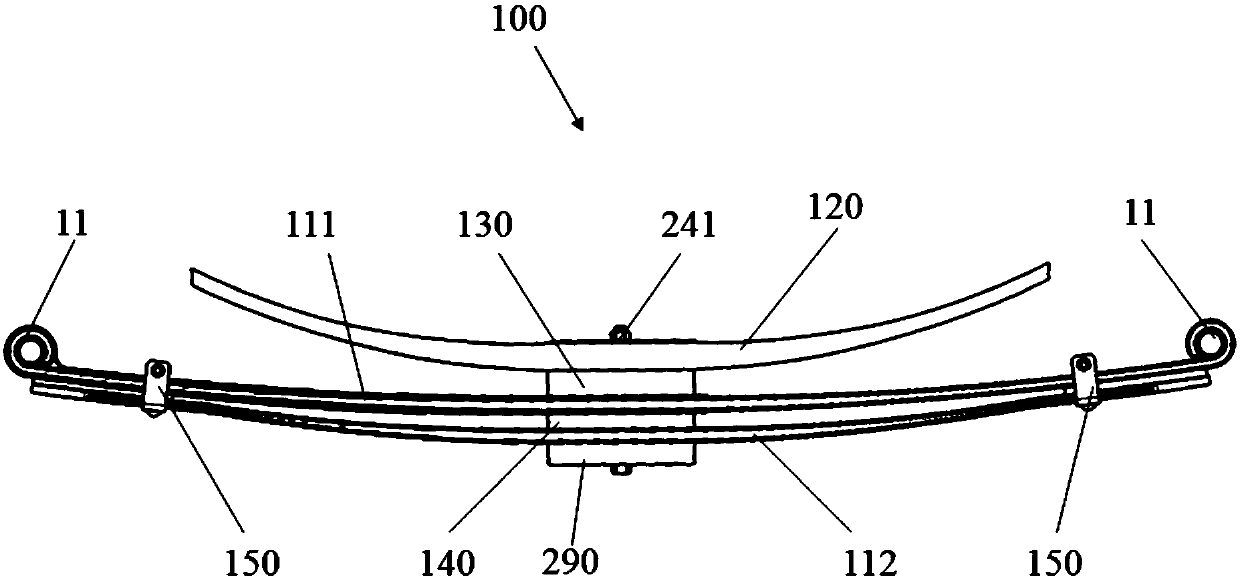

[0048] figure 1 A schematic perspective view of a composite primary and secondary spring assembly 100 according to an embodiment of the present invention is shown. The composite main and auxiliary spring assembly 100 may generally include a main spring 110 , an auxiliary spring 120 and a first spacer 130 . The main spring 110 may be made of metal material, or at least partially made of metal material. The auxiliary spring 120 is made of composite material, which can greatly reduce the weight of the main and auxiliary spring assembly. In order to reduce or even eliminate the friction between the main spring 110 and the auxiliary spring 120 , the first spacer 130 can be arranged between the main spring 110 and the auxiliary spring 120 . In one embodiment, the main spring 110 , the secondary spring 120 and the first spacer 130 are connected by a central bolt 241 . It can be understood that in other embodiments, the main spring 110 , the secondary spring 120 and the first space...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com