Silk processing equipment

A processing equipment and technology for silk, applied in the directions of mechanical cleaning, textile and papermaking, cleaning methods and utensils, etc., can solve the problems of reducing the processing quality of silk fabrics, affecting the processing of silk fabrics, easy tearing of incised fabrics, etc., to improve the cutting quality. , Simple structure, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

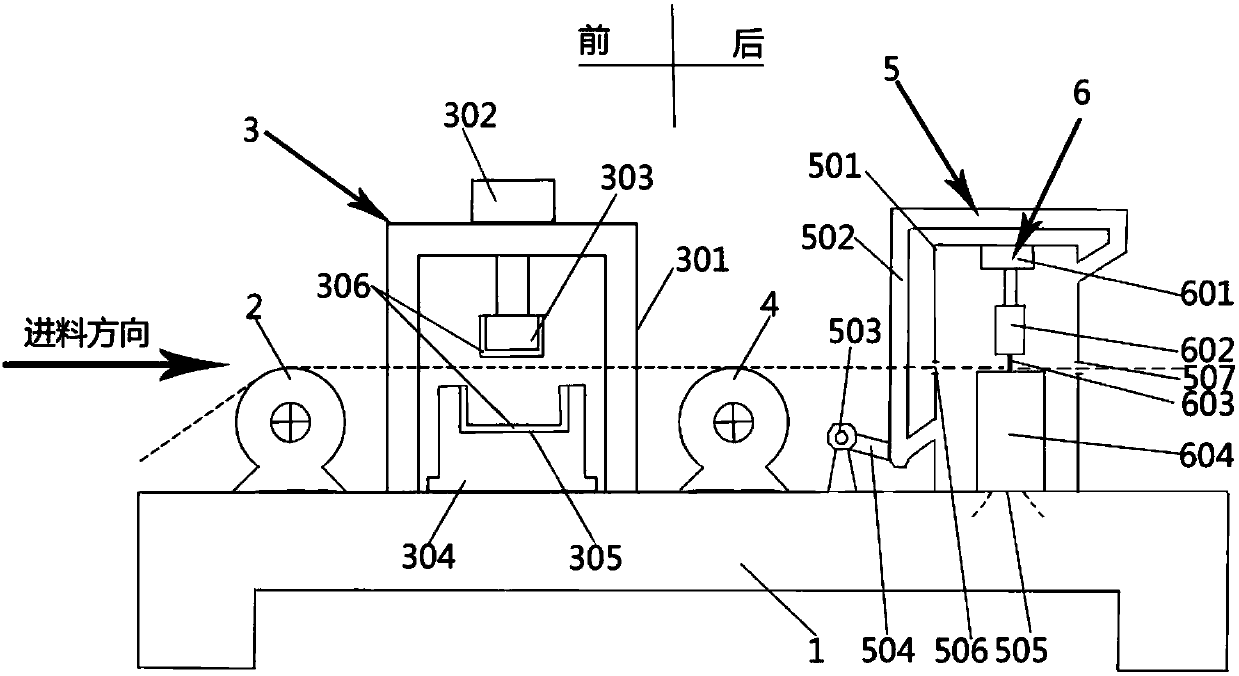

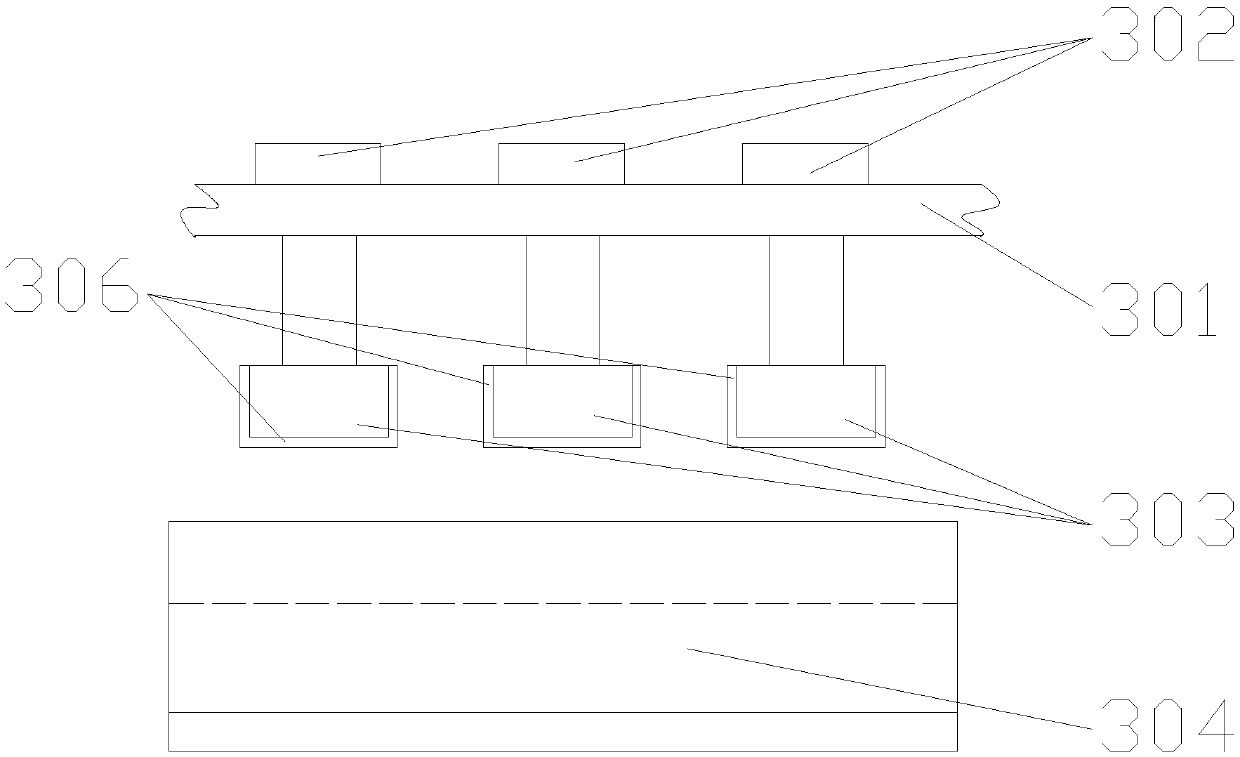

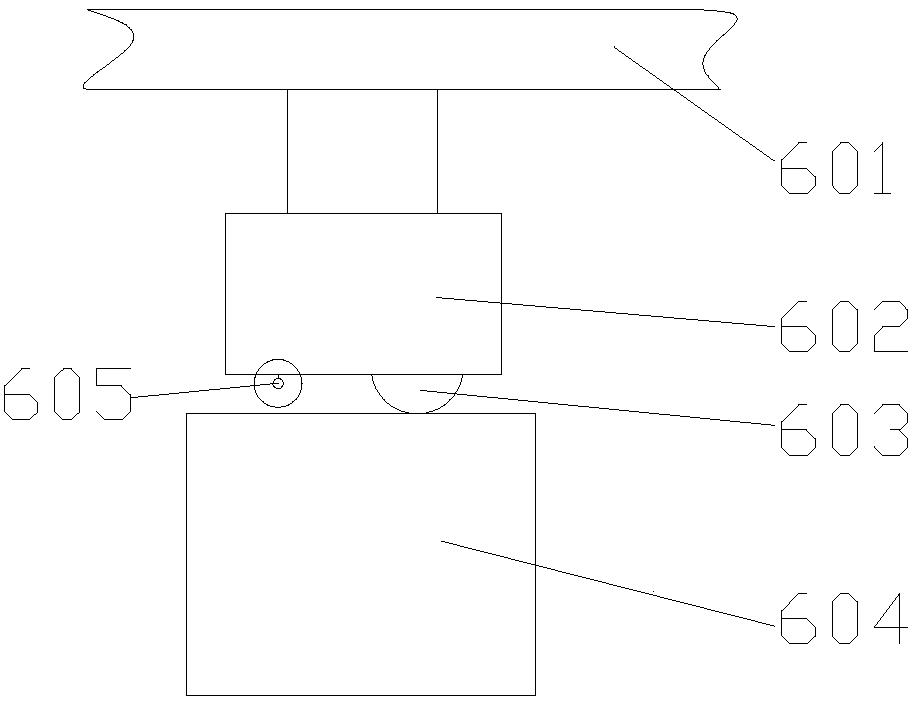

[0022] Embodiment 1 of the present invention: as Figure 1-Figure 3 As shown, a silk processing equipment includes a base 1, on which a first conveying roller 2, a fastening mechanism 3, a second conveying roller 4 and a material cleaning mechanism 5 are sequentially distributed along the feeding direction, so that the silk fabric can be smoothly to transmit. Wherein the fastening mechanism 3 comprises a fastening frame 301, a cylinder 302, an upper fastening plate 303 and a lower fastening seat 304, the fastening frame 301 and the lower fastening seat 304 are all placed on the base 1, and the fastening frame 301 Three cylinders 302 are installed on the top, and an upper fastening plate 303 is installed on the bottom of each cylinder 302. The lower fastening seat 304 is placed below the upper fastening plate 303, and the lower fastening seat 304 is also provided with the upper fastening plate 303. The matching groove 305 uses the cylinder 302 to drive the upper fastening plat...

Embodiment 2

[0025] Embodiment 2: as Figure 1-Figure 3 As shown, a silk processing equipment includes a base 1, on which a first conveying roller 2, a fastening mechanism 3, a second conveying roller 4 and a material cleaning mechanism 5 are sequentially distributed along the feeding direction, so that the silk fabric can be smoothly to transmit. Wherein the fastening mechanism 3 comprises a fastening frame 301, a cylinder 302, an upper fastening plate 303 and a lower fastening seat 304, the fastening frame 301 and the lower fastening seat 304 are all placed on the base 1, and the fastening frame 301 At least two cylinders 302 are installed on the top, and an upper fastening plate 303 is installed on the bottom of each cylinder 302. The lower fastening seat 304 is placed below the upper fastening plate 303. The matching groove 305 of the plate 303 uses the cylinder 302 to drive the upper fastening plate 303, so that the silk fabric can be pressed and fixed efficiently and firmly. The ed...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap