Stress-free clamping flexible device for high-precision standard lenses

A flexible device and standard mirror technology, applied in installation, optics, instruments, etc., can solve the problems of thermal stress, clamping stress and adhesive stress of standard mirrors, so as to solve the influence of adhesive, ensure versatility, reduce face shape effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The invention will be further described below in conjunction with the drawings.

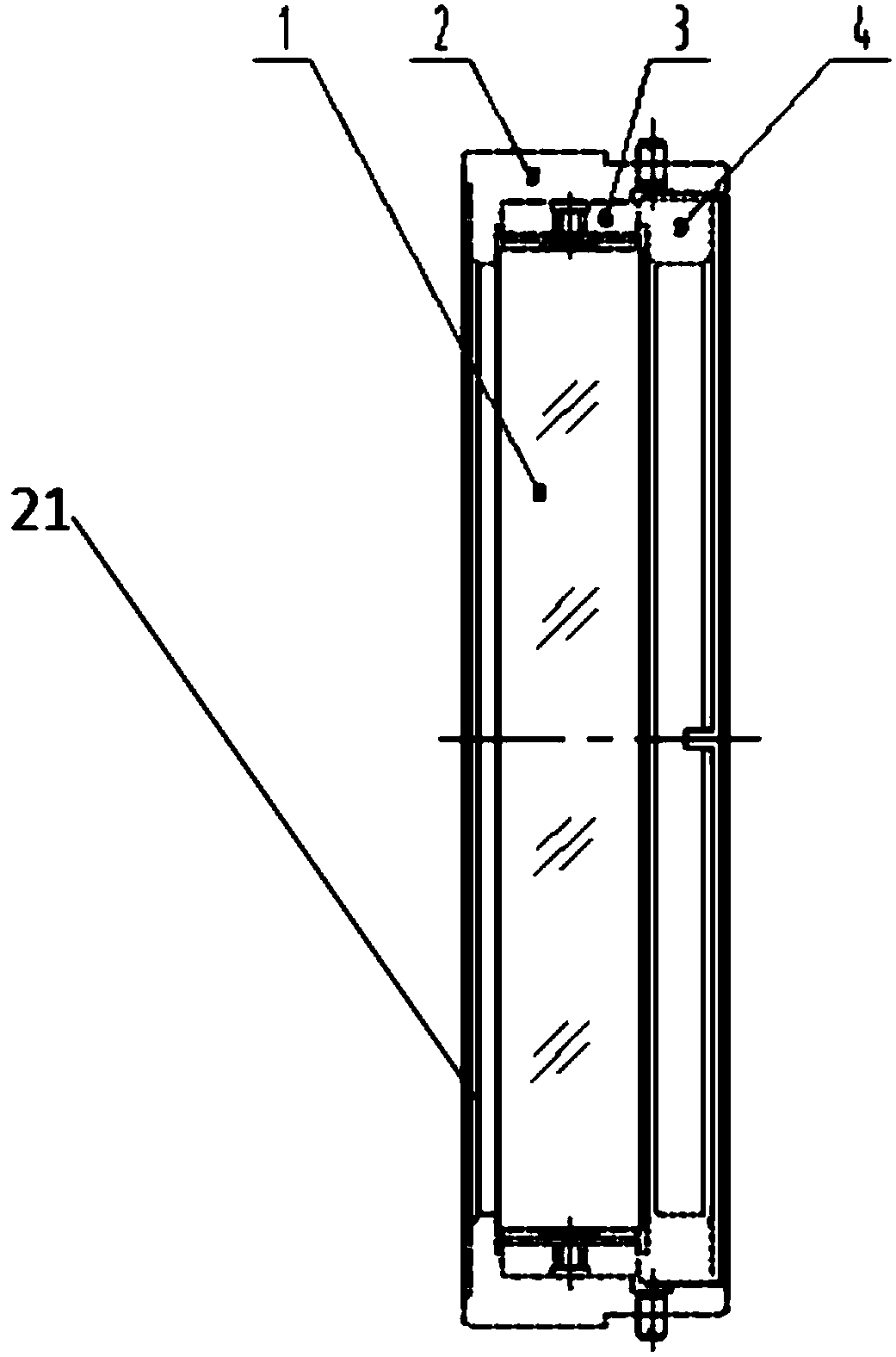

[0028] Such as figure 1 As shown, the present invention includes a standard lens frame 2, a flexible frame 3, and a pressure ring 4. The standard mirror 1 is fixed in the flexible frame 3, the flexible frame 3 is sleeved in the standard mirror frame 2, and the pressing ring 4 presses the flexible frame 3.

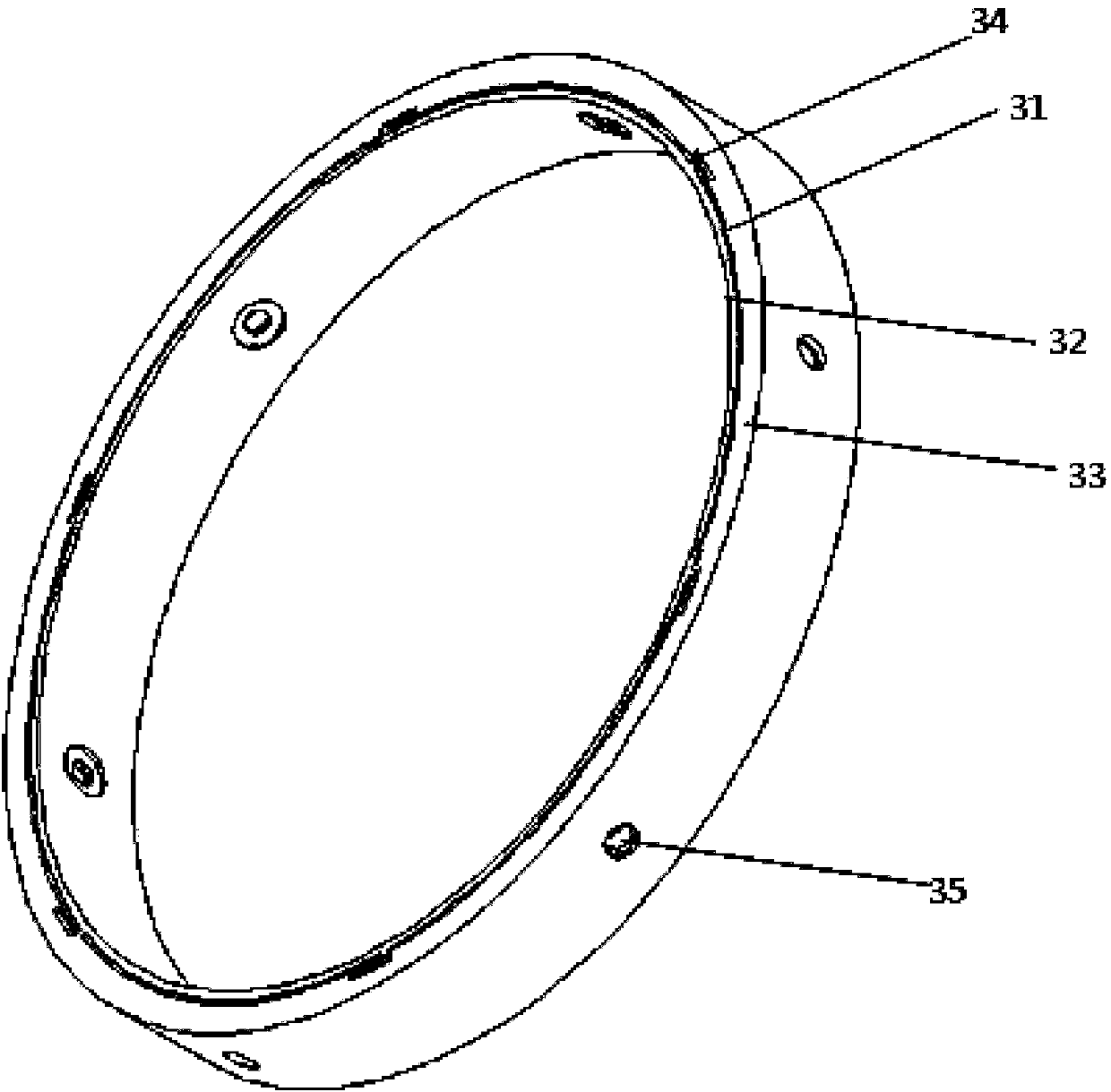

[0029] From figure 2 It can be seen that the flexible frame of the present invention is provided with a plurality of arc-shaped slits 31 with the same radius. The slits divide the flexible frame into an inner ring 32 and an outer ring 33, and the inner ring and the outer ring are connected by a flexible member 34.

[0030] The specific development process is as follows:

[0031] First, perform the optical processing of the standard mirror 1 bare mirror, and the surface shape is required to reach 1 / 50λ;

[0032] Then complete the fixing of the standard mirror 1 and the flexible frame 3. The sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com