Control Method of Ultra-rapid Cooling in Hot Continuous Rolling Line

A technology of ultra-fast cooling and control method, applied in the direction of temperature control, etc., can solve the problems such as the cooling temperature cannot be accurately controlled, the cooling speed is uneven in the thickness direction of the strip, and can reduce the temperature difference between the steel core and the surface, accurately set, guarantee The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

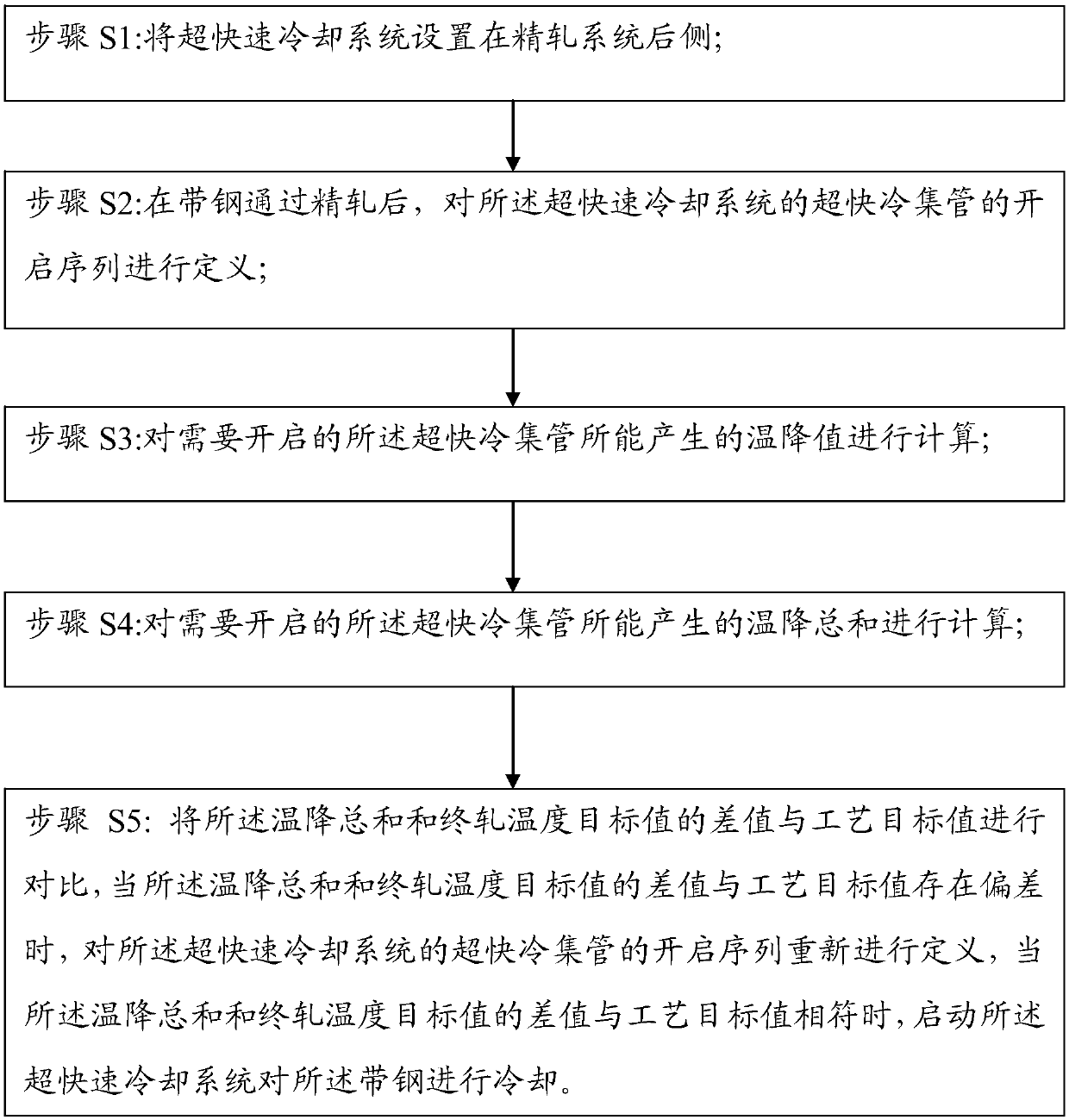

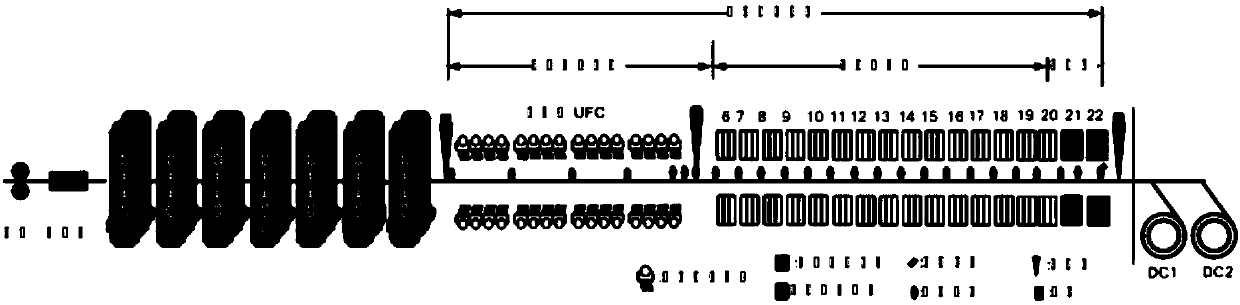

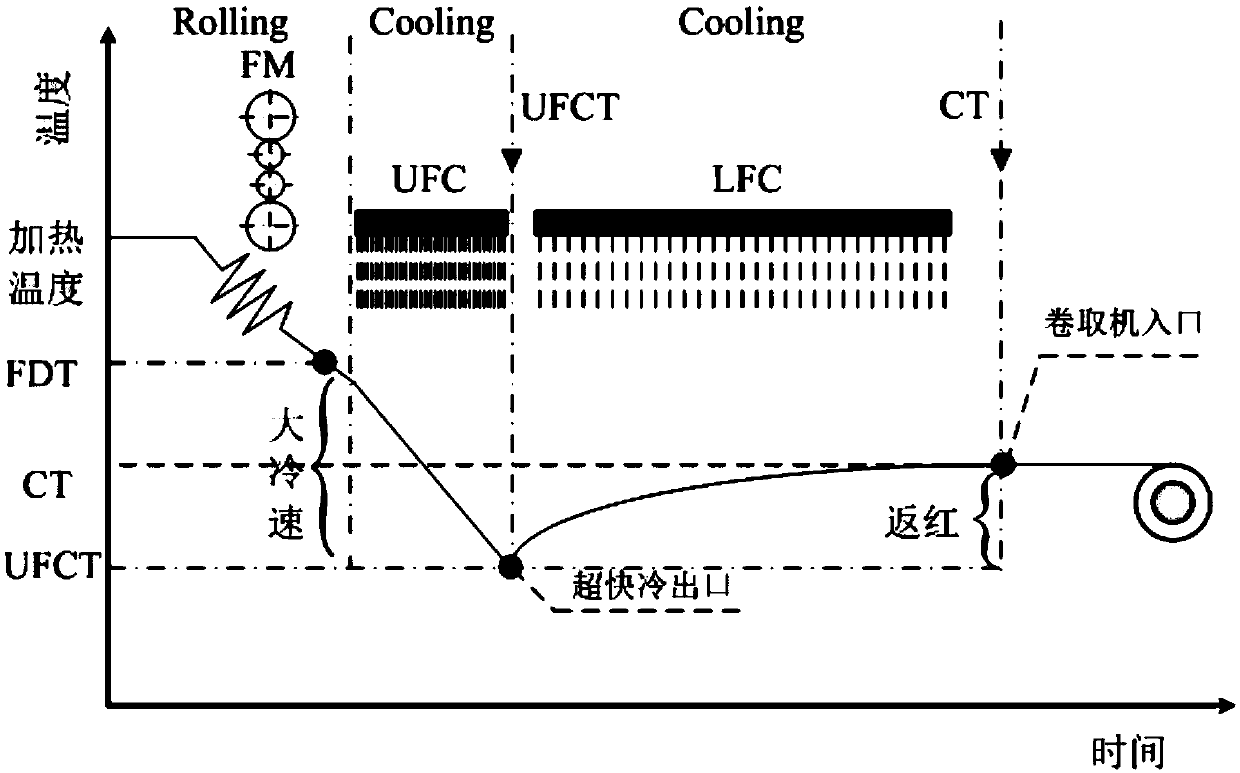

[0048] Such as figure 1 As shown, the embodiment of the present invention provides a control method for ultra-rapid cooling of hot continuous rolling line, adopting such as figure 2 In the way shown, the ultra-fast cooling equipment is arranged between the finishing rolling and the laminar cooling system, and the method is as follows: image 3 In the cooling process path shown, the ultra-fast cooling equipment is used alone to realize the water cooling process of hot-rolled strip steel after rolling, and the temperature distribution in the thickness direction of the cooling process is shown in Figure 4 As shown, the specific steps are as follows:

[0049] Step S1: setting the ultra-fast cooling system on the rear side of the finishing rolling system;

[0050] Step S2: after the strip passes through finish rolling, define the opening sequence of the ultra-fast cooling header of the ultra-rapid cooling system;

[0051] Step S3: Calculate the temperature drop that can be gen...

Embodiment 2

[0083] A control method for ultra-rapid cooling of a hot continuous rolling line provided in this embodiment, the specific steps are as follows:

[0084] Step A1: setting the ultra-fast cooling system on the rear side of the finishing rolling system;

[0085] Step A2: After the strip passes the finish rolling, define the opening sequence of the ultra-fast cooling headers, divide the ultra-fast cooling headers into 4 groups, each group consists of 10 ultra-fast cooling headers, and the ultra-fast cooling headers are divided into 4 groups. The pre-defined opening sequence of the header is: 40,39,38,1,11,21,31,10,20,30,5,15,25,35,2,12,22,32,8,18,28 ,3,13,23,33,7,17,27,37,6,16,26,36,9,19,29,4,14,24,34;

[0086] Step A3: The numbers of the ultra-fast cooling headers to be opened are: 1, 2, 5, 8, 10, 11, 12, 15, 18, 20, 21, 22, 25, 28, 30, 31, 32, 35 ,38,39,40, the corresponding cooling efficiency superposition coefficients are: 0.9,0.9,1.0,1.0,0.85,0.85,0.85,1.0,1.0,0.85,0.85,0.8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com