Disc type visual device used for deep hole welding

A disc-type, deep-hole technology, used in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve problems such as elevation, lack of intuitive monitoring, and complicated operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

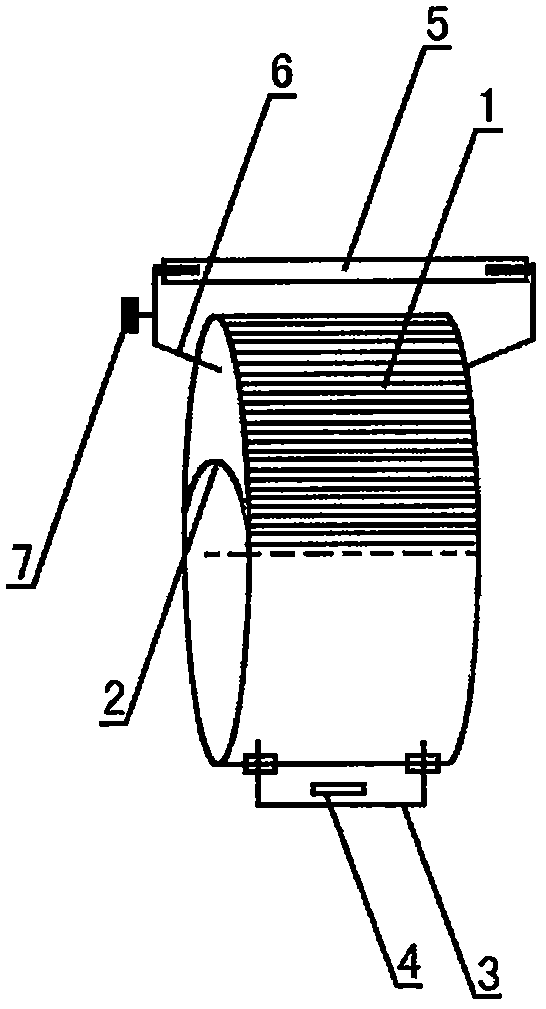

[0012] Embodiment: as shown in the accompanying drawing. A disc-type visual device for deep hole welding, including a housing (1), the housing (1) is designed with a hollow disc structure, the limited width is between the welding torch and the host, and the outer end of the housing (1) A front baffle (2) is set at 1 / 3, an open slot structure (3) and a temperature sensing sheet (4) are set at the bottom, the side rotation device (5) is connected with the support guide roller (6), and the housing ( 1) Put it on the rear side of the welding gun to dissipate the heat generated by the deep hole welding operation, and perform visual operations.

[0013] It is used for deep-hole welding disc-type visual devices, and a prompting device (7) is provided to send corresponding prompting information when the temperature inside the shell rises sharply.

[0014] It is a disc-type visual device for deep hole welding, and the way of prompting information is sound or LED light display.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com