Turnover mechanism of washing machine roller plastic piece

A washing machine drum and flip mechanism technology, which is applied in the field of the flip mechanism of the plastic parts of the washing machine drum, can solve the problems of small contact area, unfavorable manipulation, and bulky structure of the plastic parts of the washing machine drum, and achieve favorable actual control, deformation prevention, and accurate positioning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

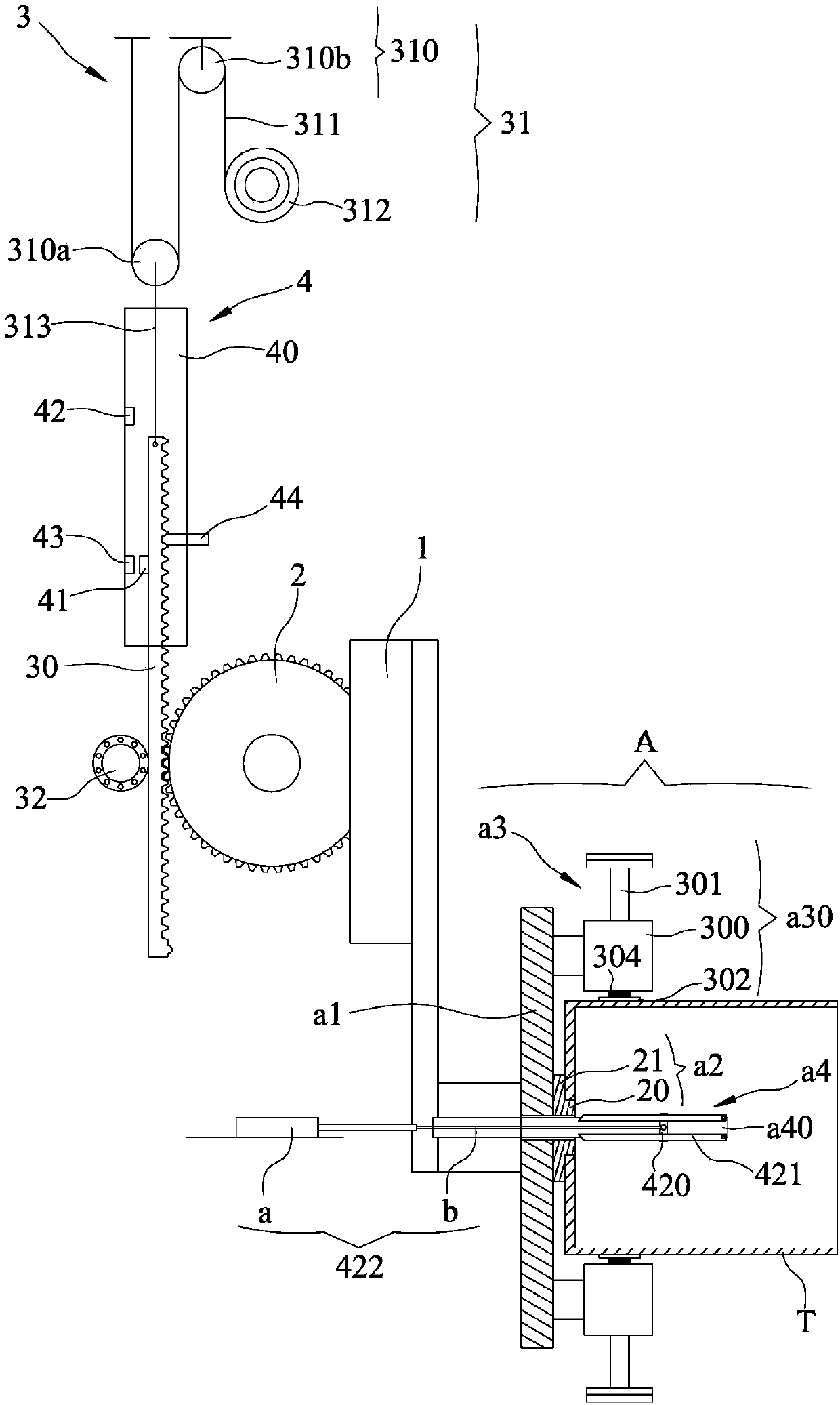

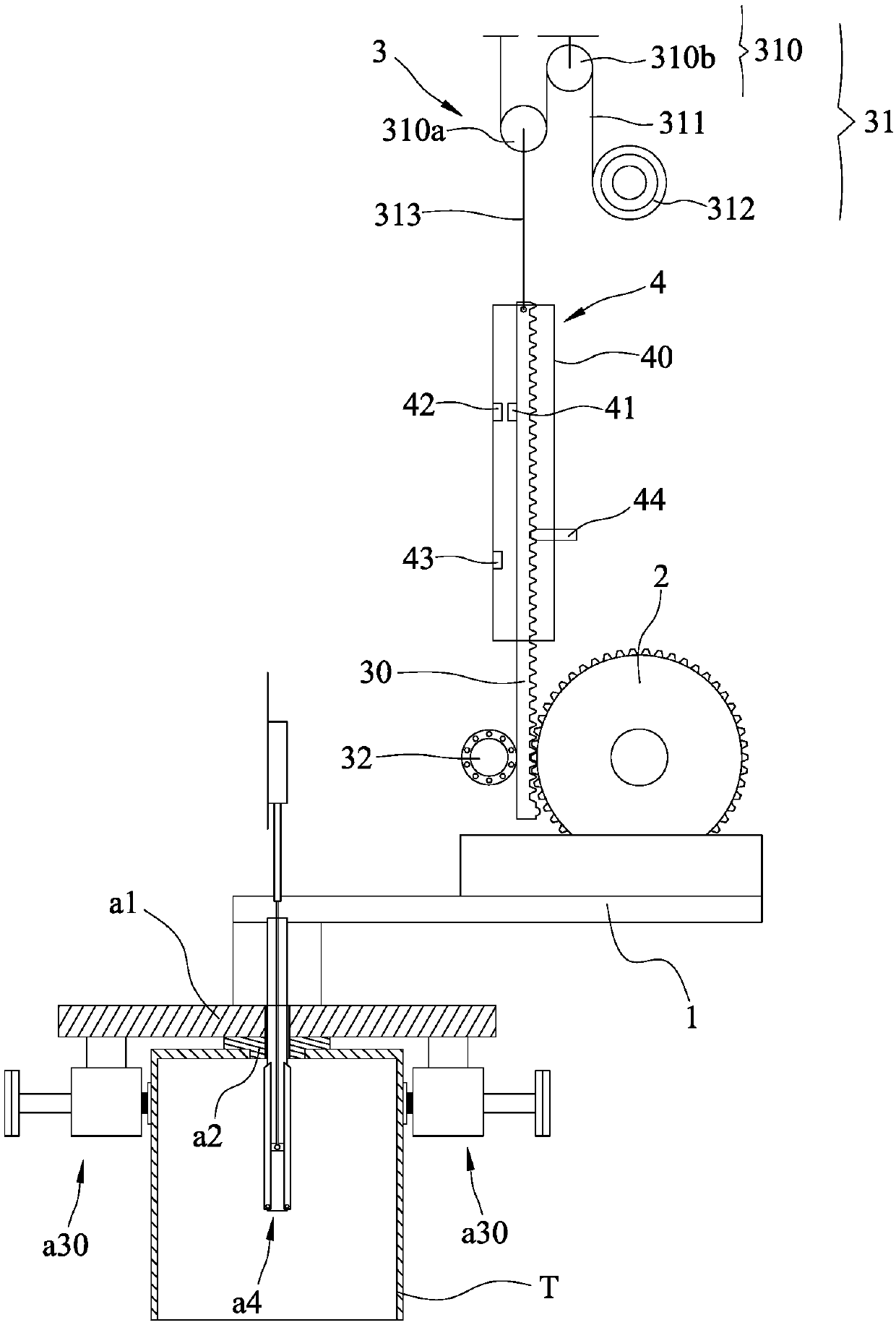

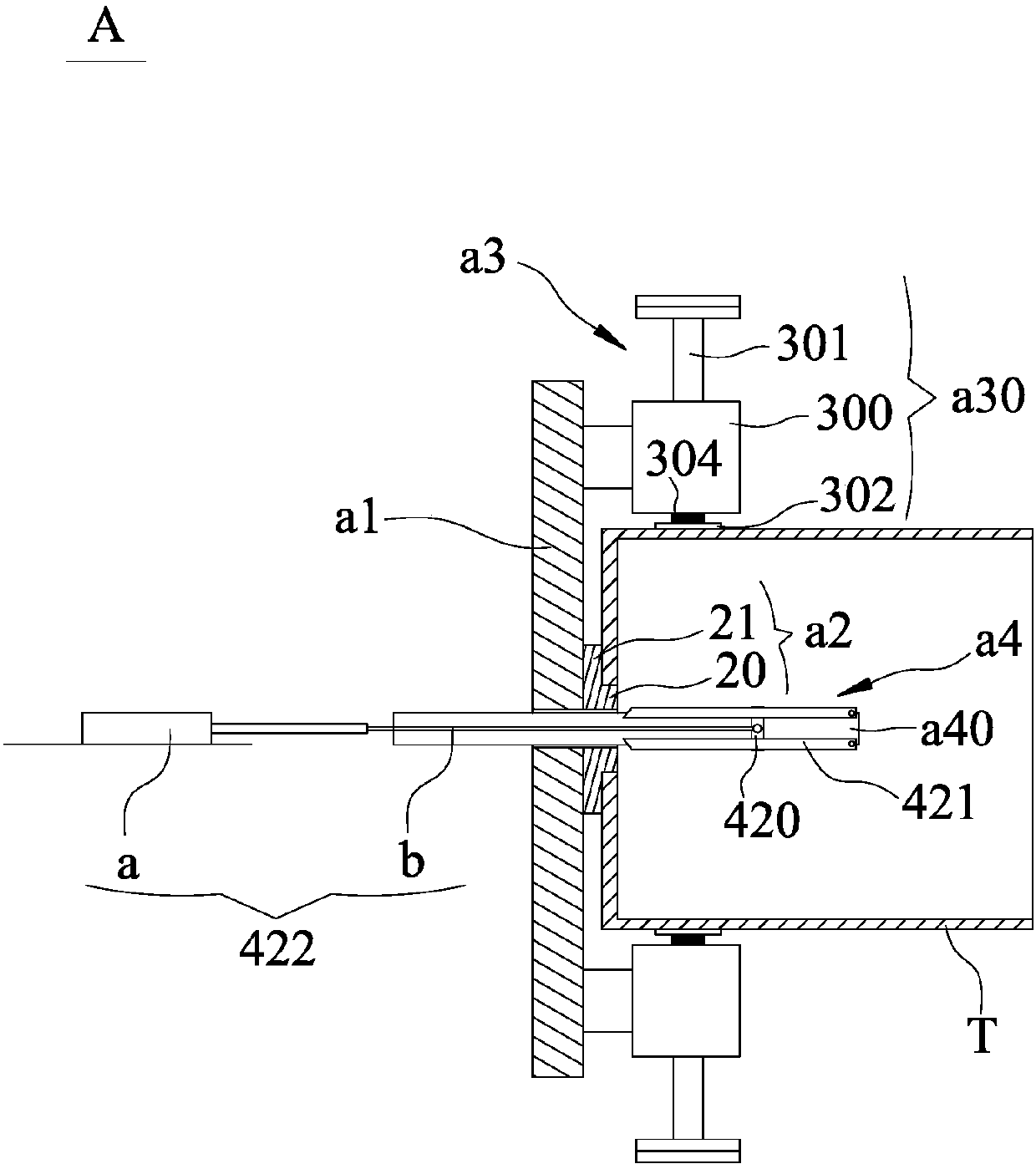

[0040] Such as Figure 1 to Figure 6 As shown, this example provides an overturning mechanism for the plastic part of the washing machine drum, which includes: a connecting frame 1, which is used to connect the positioning device A of the manipulator; Drive assembly 3, it is used to drive the rotation of gear 2, and it comprises the rack bar 30 that is positioned at the opposite side of connecting frame 1 and matches with gear 2, is used to drive the drive that rack bar 30 moves along its length direction Component 31 : the control limit assembly 4, which is used to control the movement of the rack bar 30, so that when the clip arm is in a horizontal or vertical state, the rack bar 30 stops moving.

[0041] The rack bar 30 is extended along the vertical direction. The connecting frame 1 is fixedly clamped on one side of the gear 2 .

[0042] The driving part 31 includes a pulley block 310 located at the top of the rack bar 30 , a traction rope 311 and a winding roller 312 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com