Production device and process for bubble-free shoe materials

A technology of production equipment and production technology, which is applied in the field of production equipment and production technology of non-bubble shoe materials, can solve problems affecting the quality of shoe materials, and achieve the effect of enhancing market competitiveness and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

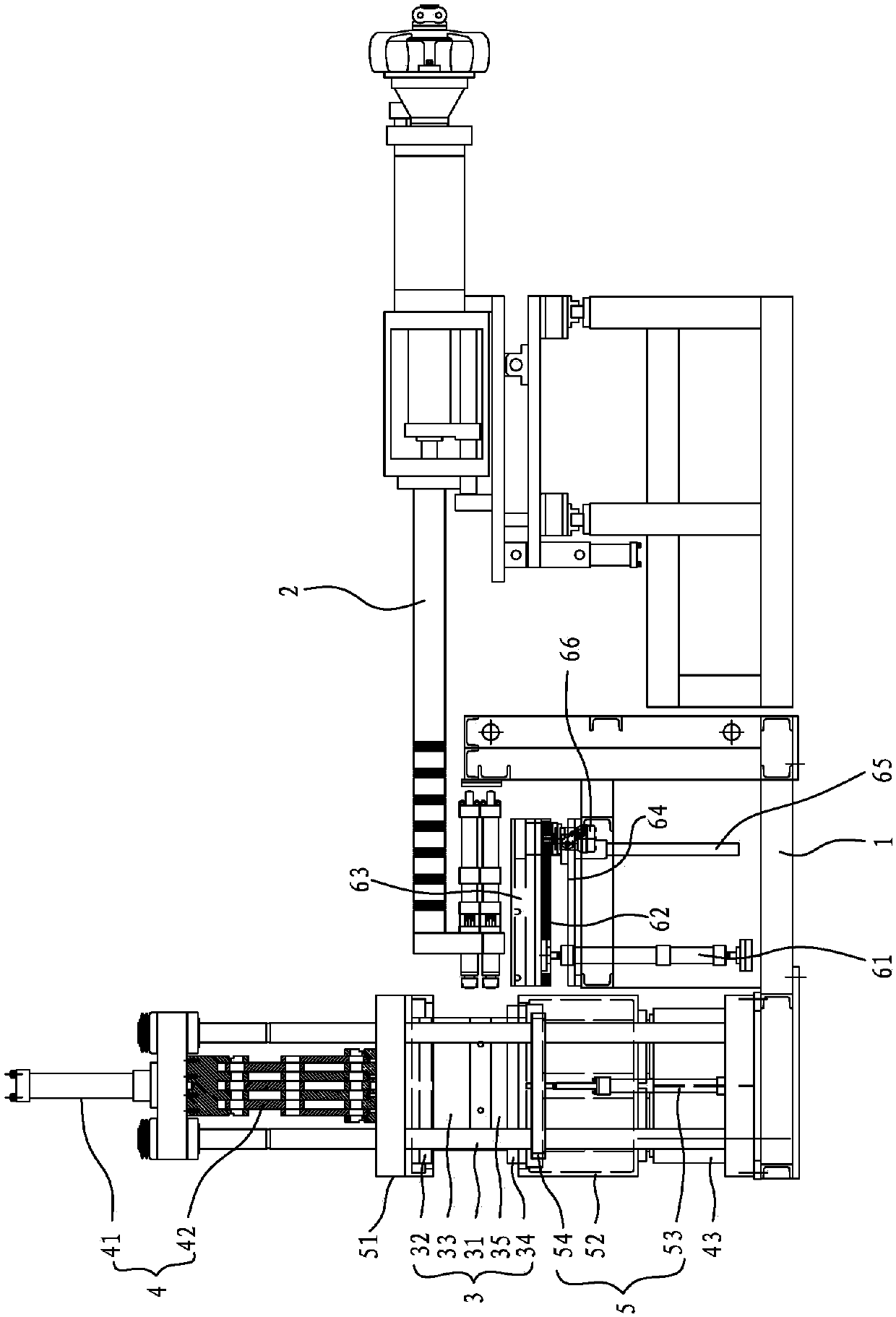

[0032] Such as figure 1 As shown, the present invention relates to a production equipment for air-free shoe materials, including a frame 1, an injection mechanism 2, a molding die 3, a die opening mechanism 4, and a vacuuming mechanism 5. In the present invention, the air-free The shoe material can be two-color or three-color shoe material.

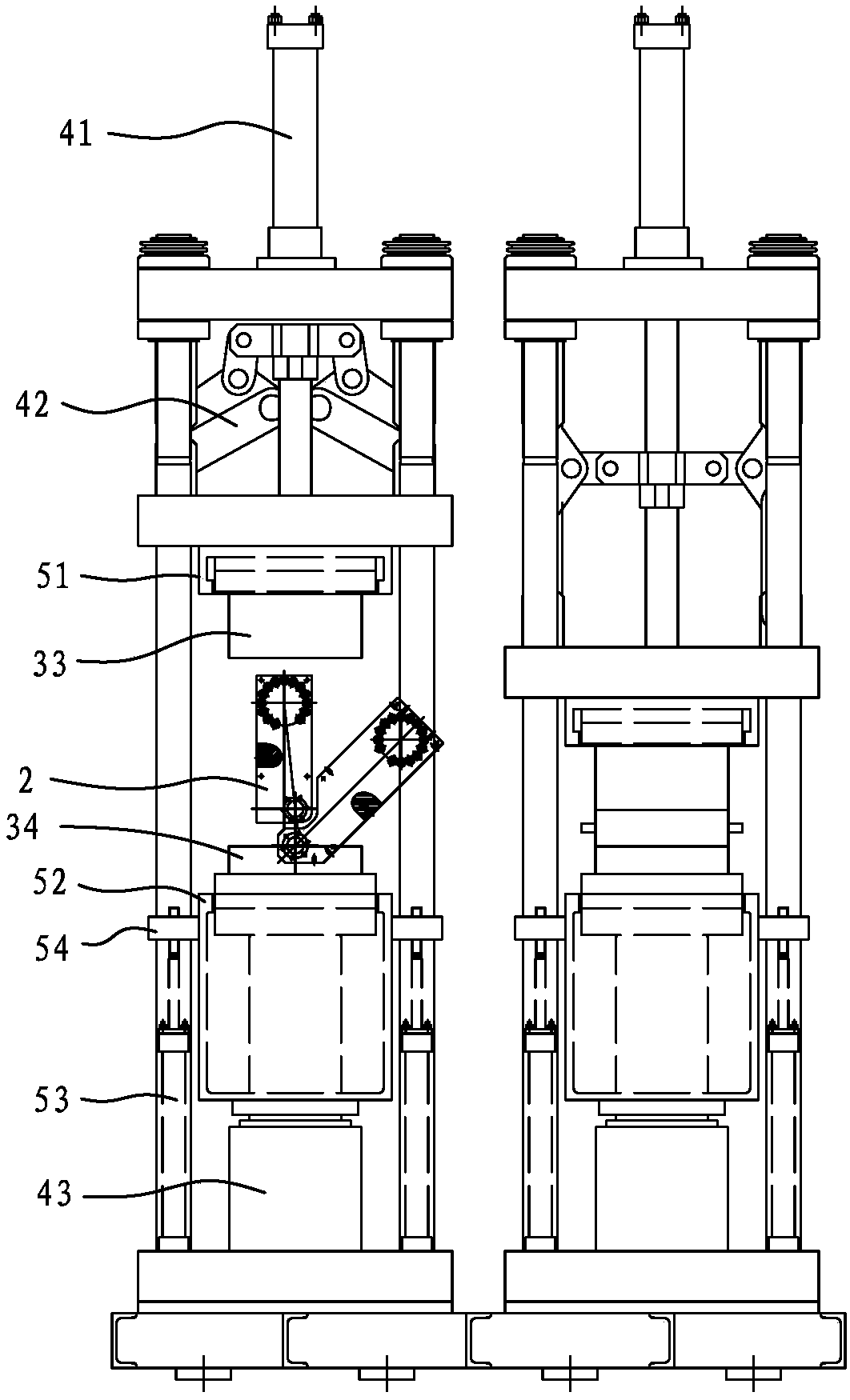

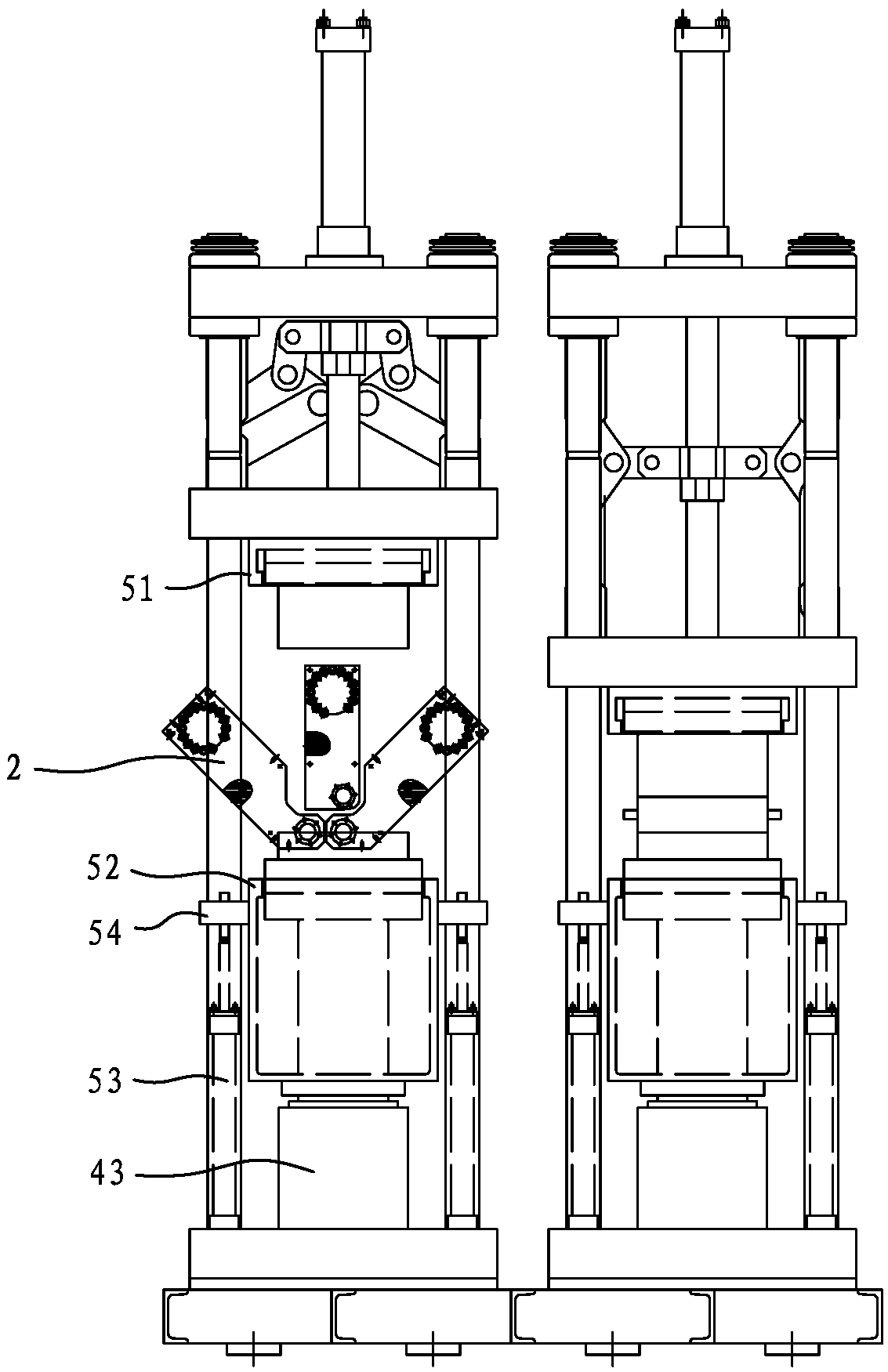

[0033] The injection mechanism 2 injects shoe material raw materials into the forming mold 3. The forming mold 3 has a column 31, an upper heating plate 32, an upper mold 33, a lower heating plate 34 and a lower mold 35. The upper heating plate 32 is located at Above the upper mold 33 , the lower heating plate 34 is located below the lower mold 35 .

[0034] The die opening mechanism 4 has a mold opening and closing cylinder 41, a crank assembly 42 and a booster cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com