Automobile synchronizer with unidirectional locking surface

A one-way lock and synchronizer technology, applied in clutches, mechanical drive clutches, mechanical equipment, etc., can solve the problems of reducing vehicle power and fuel economy, reducing transmission life, and large impact force of gear shafts, etc., to improve fuel consumption. Economical, improved power, large friction diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

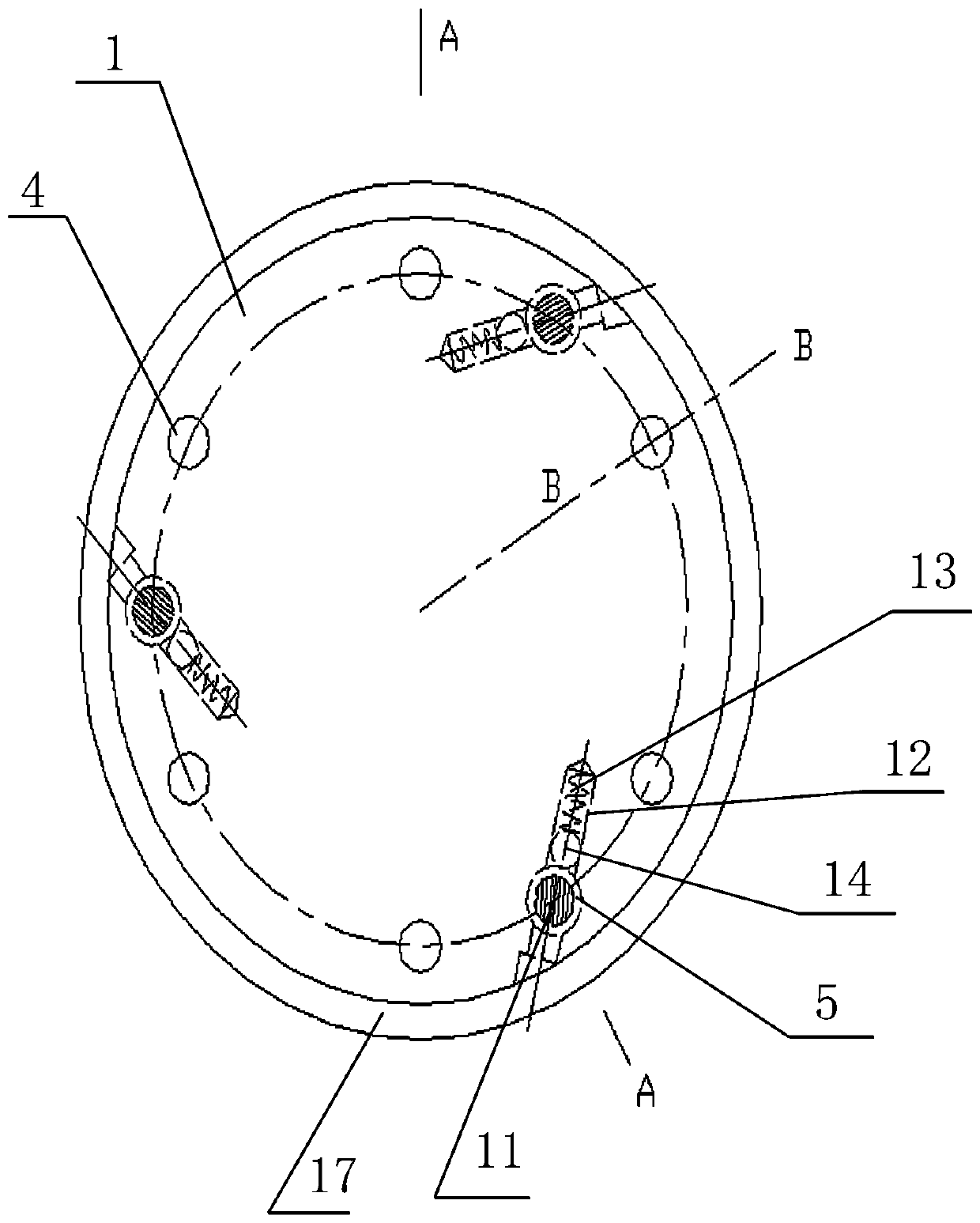

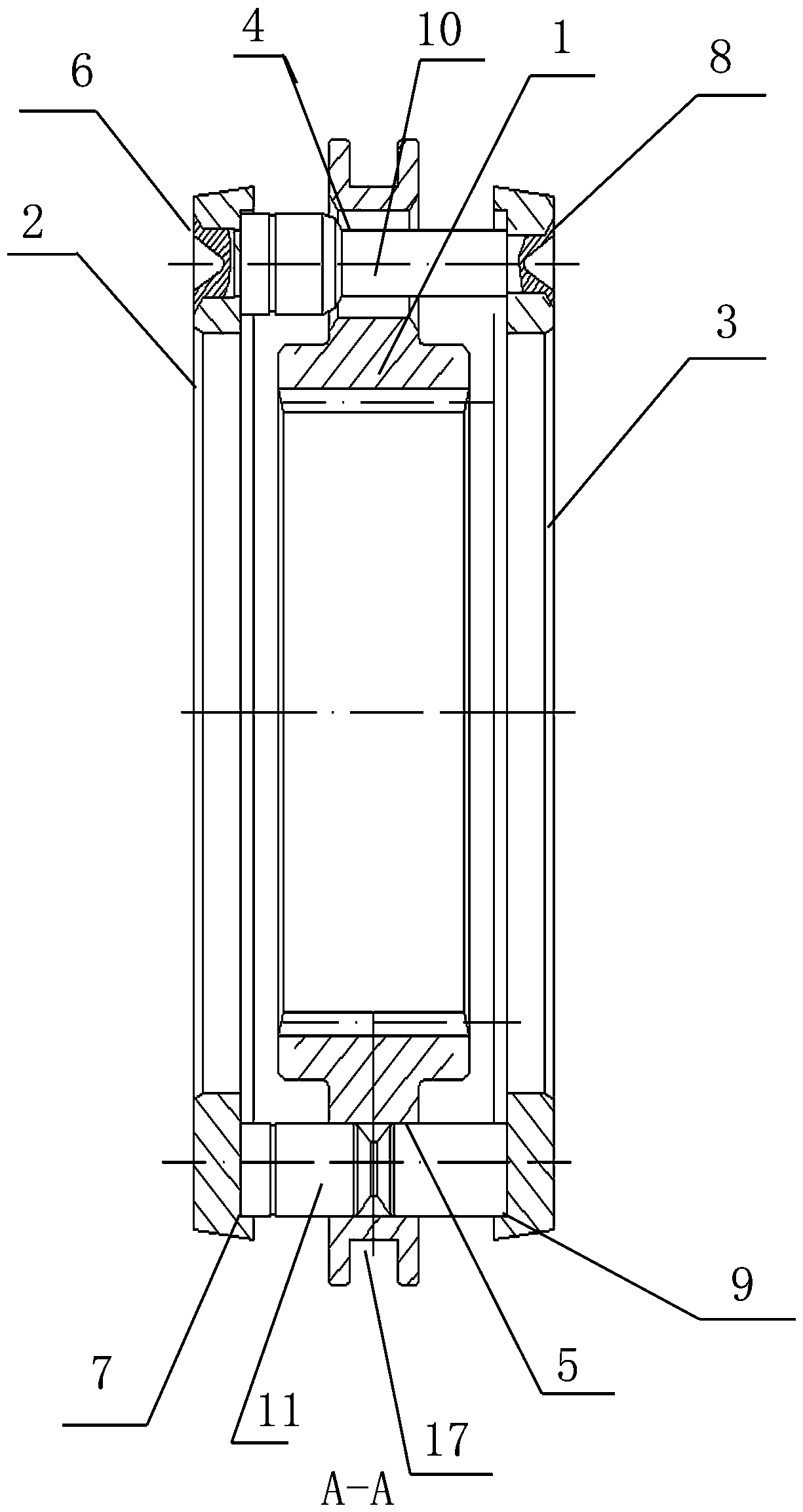

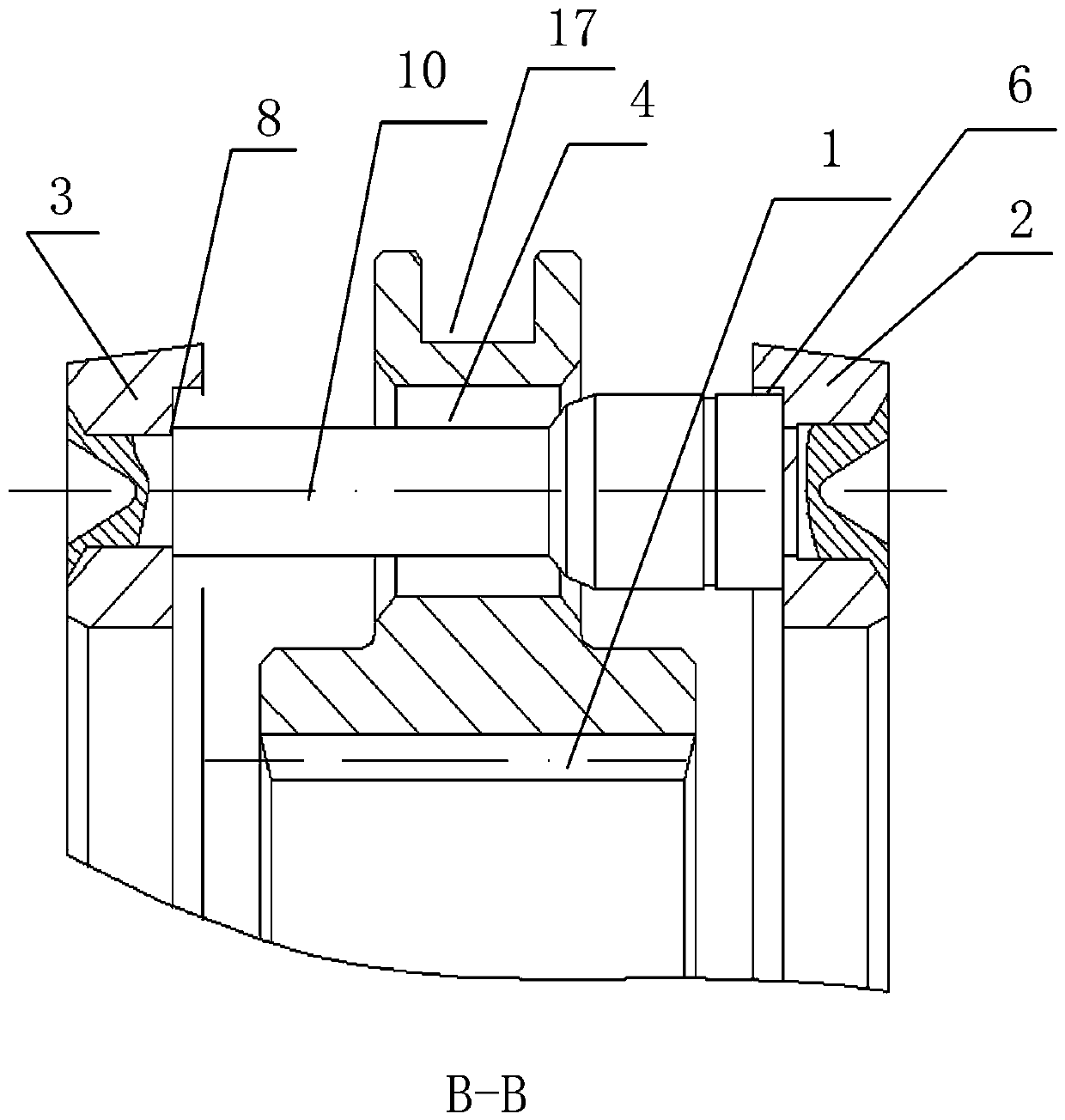

[0011] exist figure 1 , figure 2 , image 3 and Figure 4 Among them, the present invention provides a one-way locking surface automobile synchronizer, which includes a synchronous sliding sleeve 1, and a left synchronous cone ring 2 and a right synchronous cone ring 3 are respectively arranged on both sides of the synchronous sliding sleeve 1. There are several locking holes I4 and several positioning holes I5 evenly distributed in the circumferential direction on the sleeve 1, and there are six locking holes I4 and three positioning holes I5 evenly distributed in the circumferential direction on the synchronous sliding sleeve 1 in this embodiment , there are several locking holes II6 and several positioning holes II7 evenly distributed in the circumferential direction on the left synchronous cone ring 2, and in this embodiment there are three locking holes II6 and three evenly distributed circumferentially on the left synchronous cone ring 2 Positioning hole II7, there a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com