Follow-up parallel roller overrunning clutch

An overrunning clutch and follow-up technology, applied in clutches, one-way clutches, mechanical equipment, etc., can solve the problems of increasing the load capacity of overrunning clutches, low processing efficiency of overrunning clutches, and the inability to set a large number of rollers, etc., to ensure that The effect of service life, avoiding mechanical failure, and reducing processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

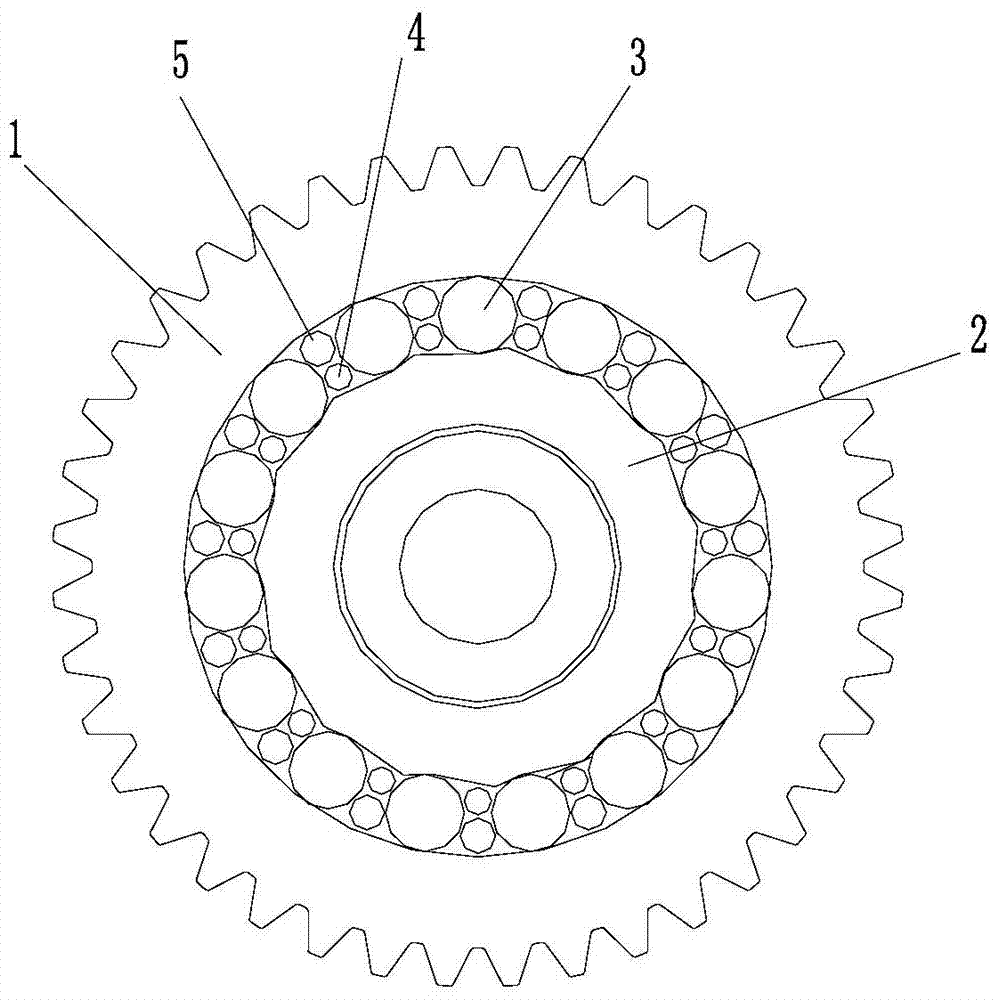

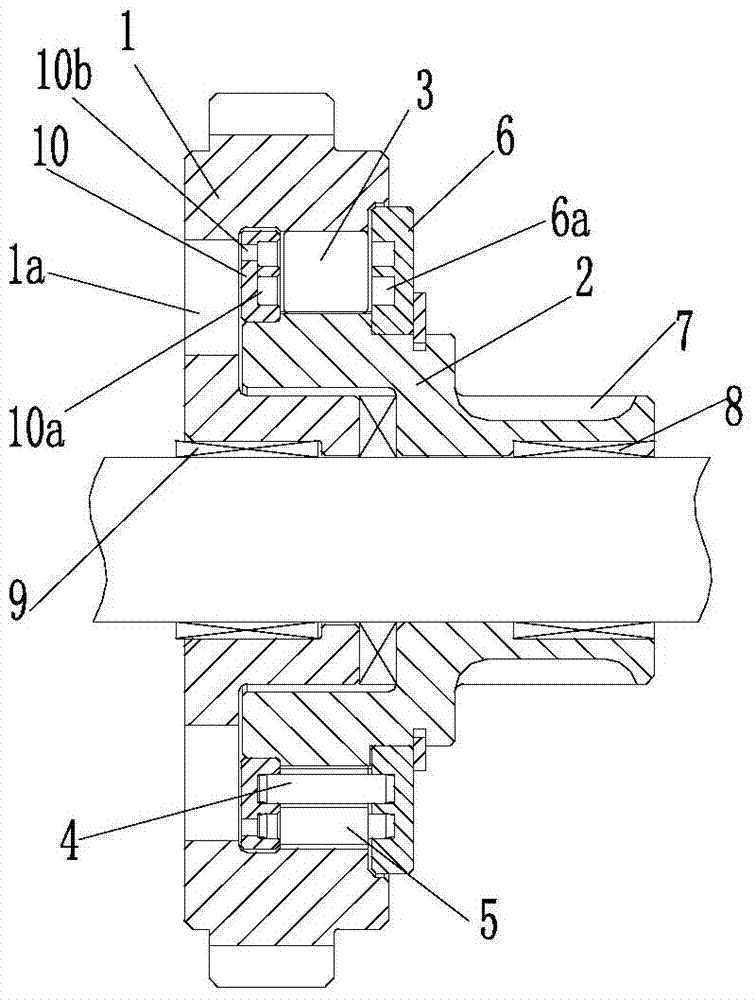

[0021] figure 1 It is a schematic diagram of the structure of the present invention, figure 2 for figure 1 As shown in the sectional view along the radial direction, the follow-up type parallel roller overrunning clutch of this embodiment includes an outer ring 1, an inner ring 2 and a rolling body 3, and the outer ring 1 and the inner ring 2 are formed for The meshing space through which the rolling elements 3 are engaged or separated also includes a supporting roller assembly, which at least includes a set of supporting rollers parallel to the axis of the overrunning clutch and spaced apart from the rolling elements. Outer support rollers and inner support rollers arranged radially and in parallel, the outer circles of the outer support rollers and the outer circles of the inner support rollers are in contact with the outer circles of the adjacent rollers, the outer support rollers and the inner support rollers The clutch is set in a movable manner in the circumferential ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com