3D printing pen nozzle replacing device

A 3D printing pen and nozzle technology, applied in the field of 3D printing, can solve the problems of restricting the shape diversity of 3D products and the single thickness and shape of the fuse, and achieve the effect of quick replacement, reasonable structure design and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

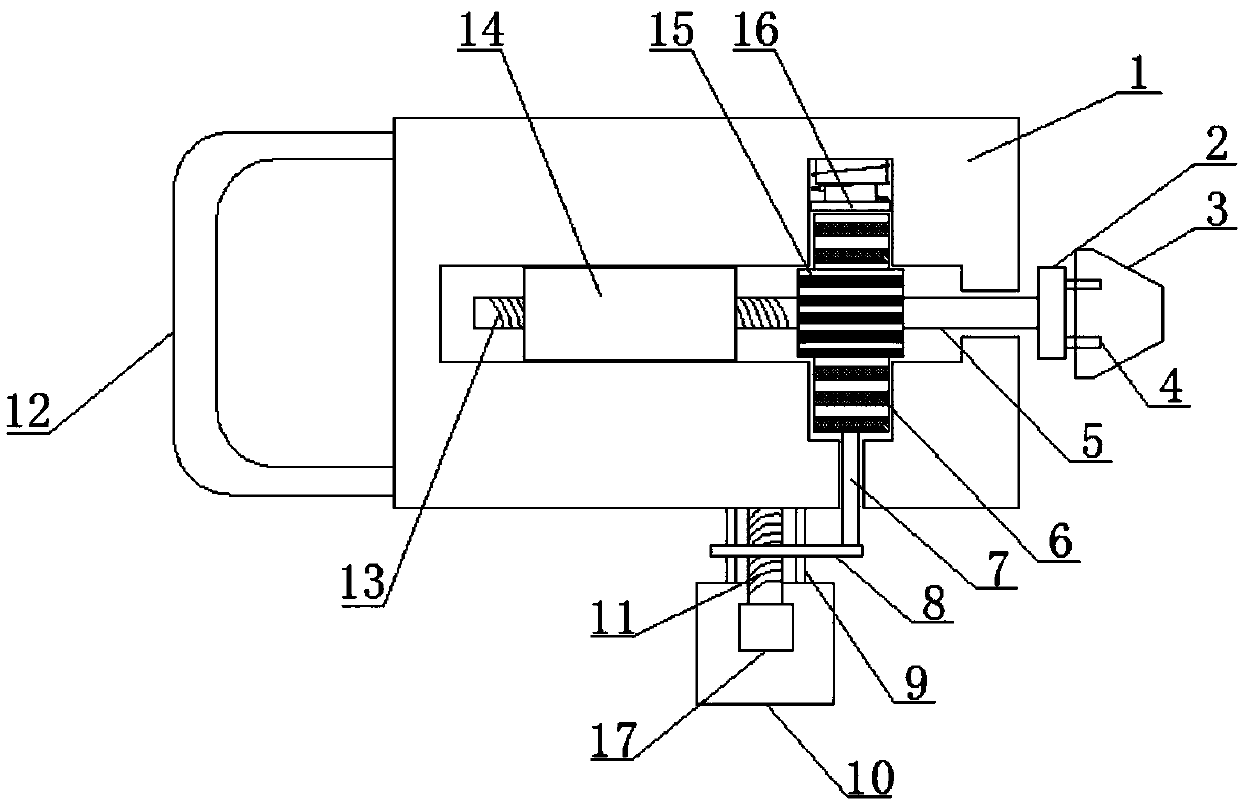

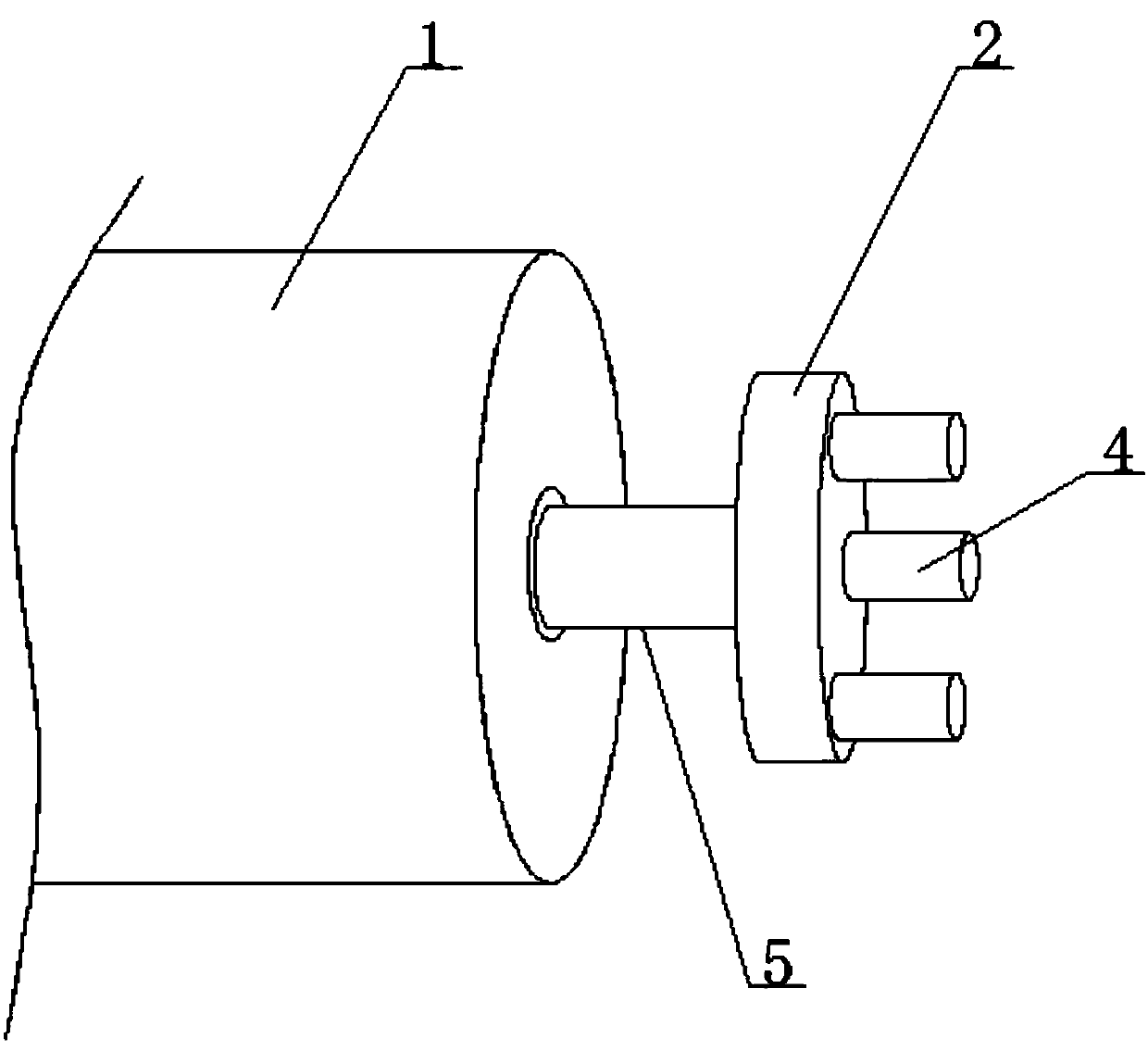

[0016] refer to Figure 1-2 , a 3D printing pen nozzle replacement device, including a fixed plate 1, the middle of the fixed plate 1 is provided with a device cavity, the inner wall of the device cavity is fixedly connected with a fixed block 14, the fixed block 14 is provided with a first threaded rod 13, fixed The block 14 is threadedly connected with the first threaded rod 13, and the end of the first threaded rod 13 away from the inner wall of the device cavity is fixedly connected with a gear 15, and the rotation of the gear 15 drives the first threaded rod 13 to rotate, and the rotation of the first threaded rod 13 makes the first threaded rod 13 rotate. 13 mo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap