Bearing transfer cart in workshop

A bearing and trolley technology, applied in the field of bearing manufacturing, can solve problems such as inconvenient unloading, and achieve the effect of quick loading and unloading and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

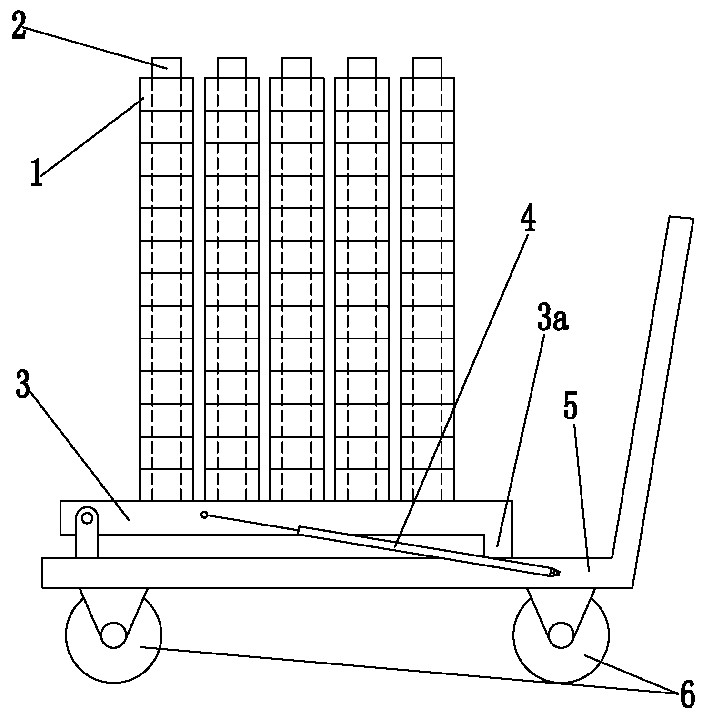

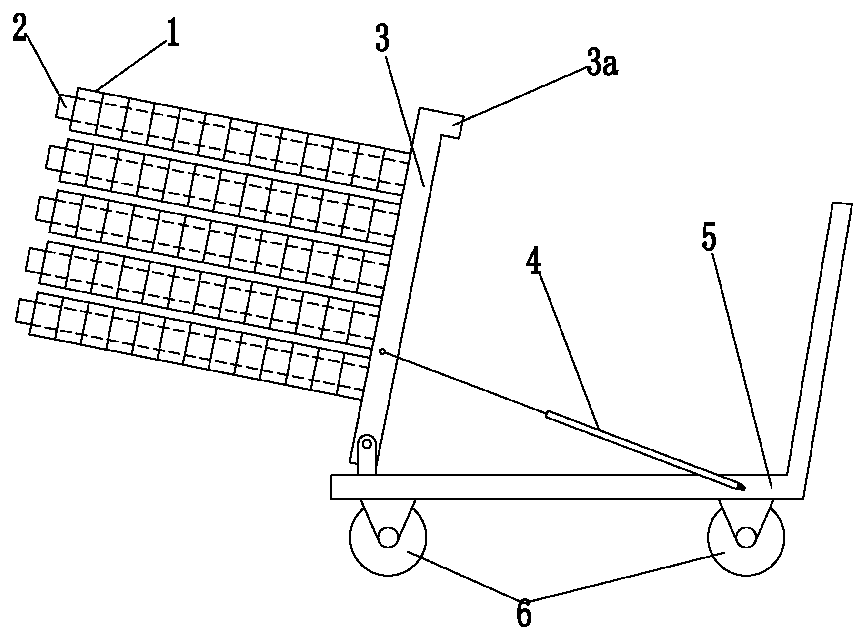

[0009] Such as Figure 1-2 As shown, a bearing transfer trolley in a workshop includes a vehicle frame 5 with both hand-push function and loading function, and also includes two pairs of walking wheels 6 respectively installed on the front and rear sides of the vehicle frame 5, and also includes a floor that can be turned up and down at one end. The overturning frame 3 installed on the vehicle frame 5 also includes an overturning oil cylinder 4 that can drive the overturning frame 3 to turn up and down, and also includes a plurality of sleeve columns 2 that are arranged on the overturning frame 3 and are used to cover the bearing 1, and the overturning frame The free end of 3 is provided with support pin 3a, and when overturn frame 3 is placed on the vehicle frame 5 flatly, support pin 3a contacts with vehicle frame 5, and all sleeve columns 2 are in upright state.

[0010] When the bearing 1 needs to be loaded, the bearing 1 can be set on the sleeve column 2, so that the bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com