Method for static measurement and elimination during polyester chip packaging operation

A polyester chip, electrostatic measurement technology, applied in the direction of static electricity, packaging, electrical components, etc., can solve problems such as electrostatic ignition, electric shock for operators, and achieve the effect of solving electrostatic electric shock, preventing fire accidents, and achieving good technical effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

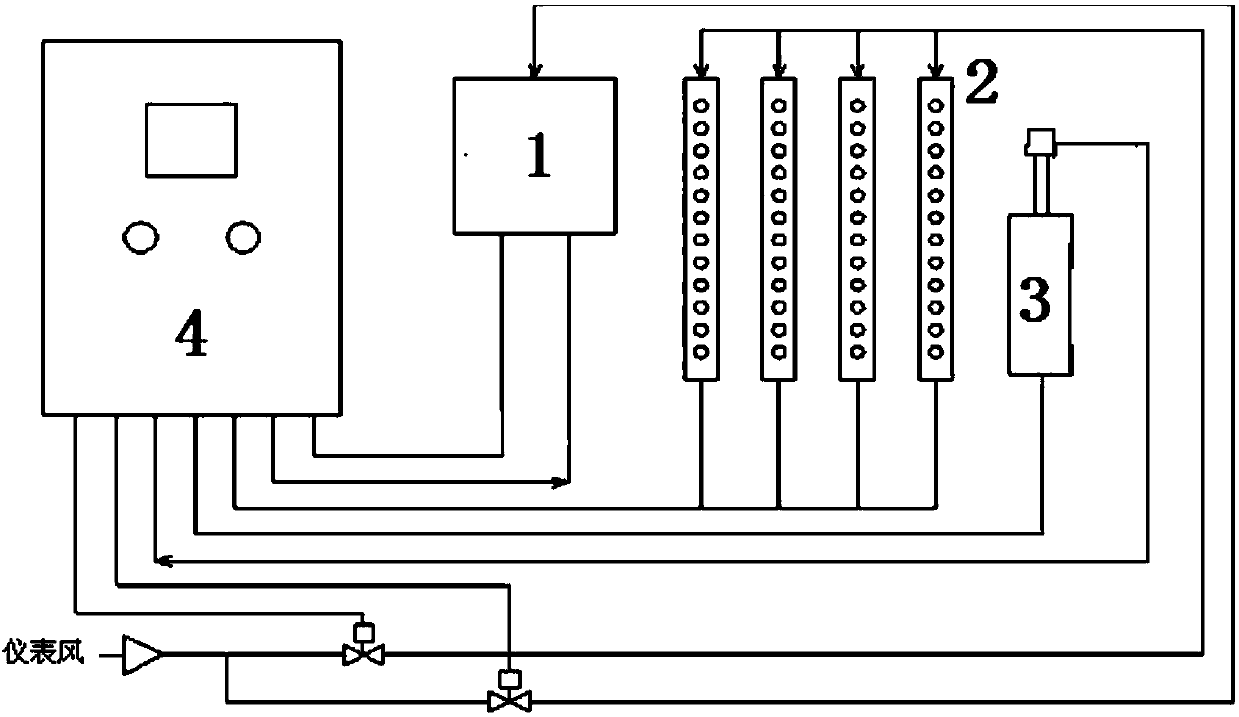

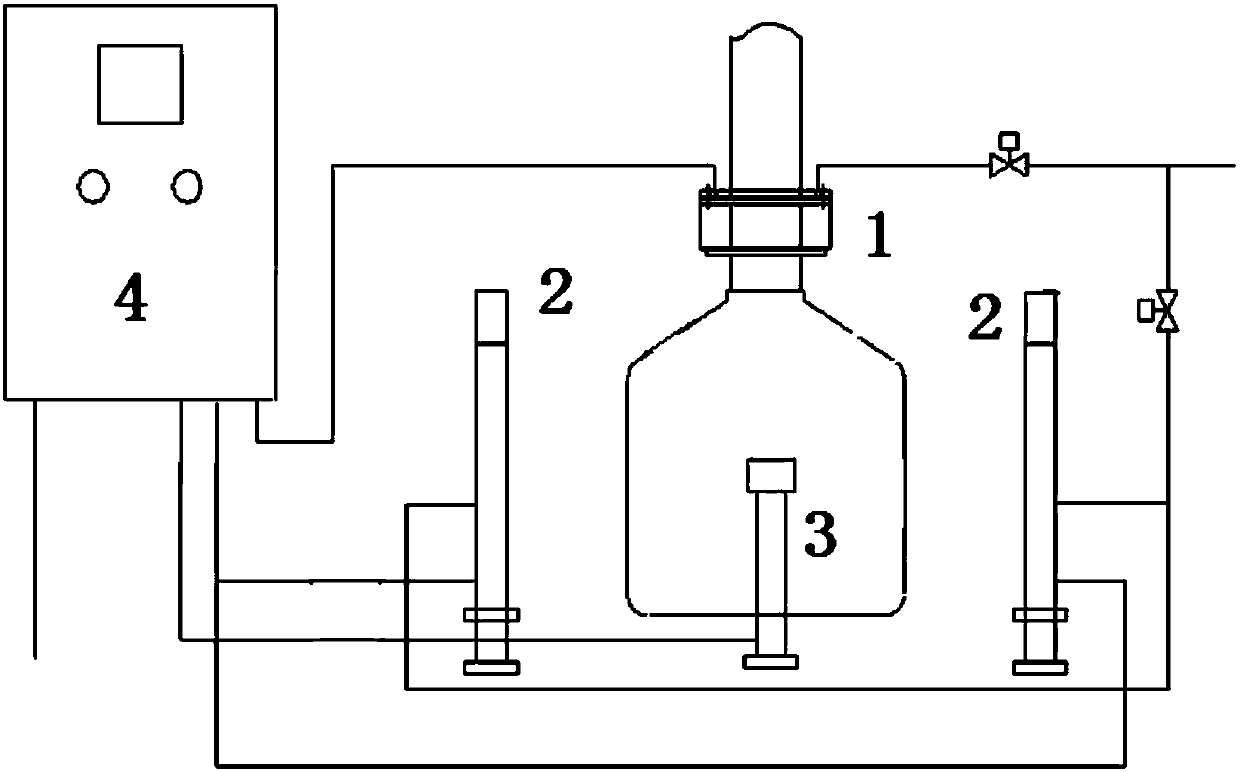

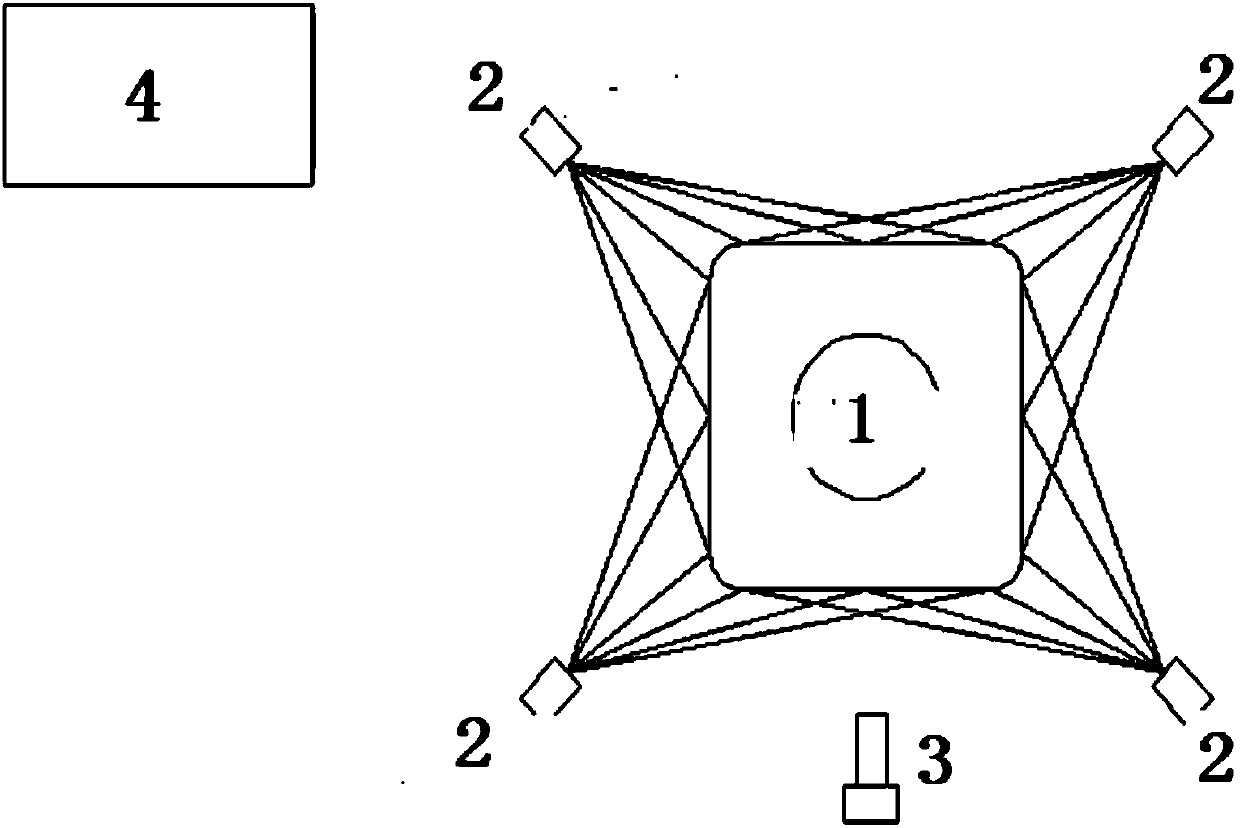

[0018] Such as Figure 1-Figure 3 As shown, during the packaging process of polyester chips, a pipeline static eliminator is installed on the upper end of the feeding pipe to eliminate the static electricity generated by the friction between polyester chips and the pipe during feeding. The box opens the static eliminator, and the charged ions generated by the static eliminator neutralize the charged material ions to eliminate the static electricity carried by the material, thereby avoiding the occurrence of electrostatic discharge of the material. In addition, 4 surface static eliminators are installed around the packaging bag. The angle between the two adjacent surface static eliminators and the center of the pipeline static eliminator is 90°. The surface static eliminator is coaxial and parallel to the packaging bag. To eliminate static electricity on the surface of the packaging bag. At the same time, an electrostatic measuring instrument is installed at the operating plat...

Embodiment 2

[0021] According to the conditions described in Example 1, only 2 pipeline static eliminators are installed at the upper end of the feeding pipe, 6 surface static eliminators are arranged around the packaging bag, and the two adjacent surface static eliminators and the center of the pipeline static eliminator The connecting angle is 60°. It can also solve the electrostatic shock problem of operators in the polyester chip packaging process, and prevent fire accidents caused by static electricity.

Embodiment 3

[0023] According to the conditions described in Example 1, only 2 pipeline static eliminators are installed at the upper end of the feeding pipe, 12 surface static eliminators are arranged around the packaging bag, and the two adjacent surface static eliminators and the center of the pipeline static eliminator The connecting angle is 30°. It can also solve the electrostatic shock problem of operators in the polyester chip packaging process, and prevent fire accidents caused by static electricity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com