Machine frame

A rack-and-frame technology, applied in machine/support, supporting machine, mechanical equipment, etc., can solve the problems of looseness, insufficient support, and the rack is not suitable for repeated disassembly and assembly, so as to facilitate disassembly, assembly and fixation solid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

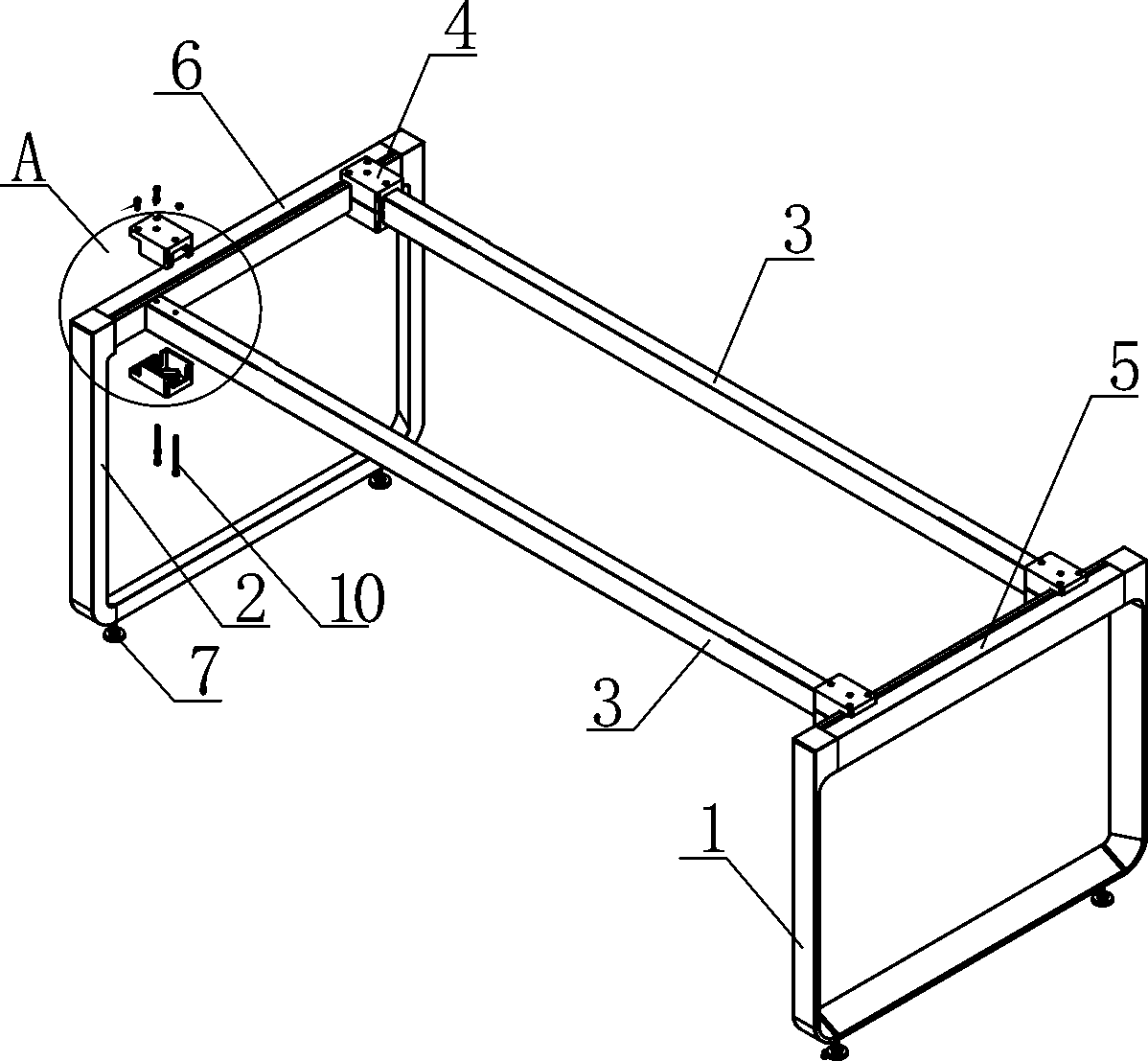

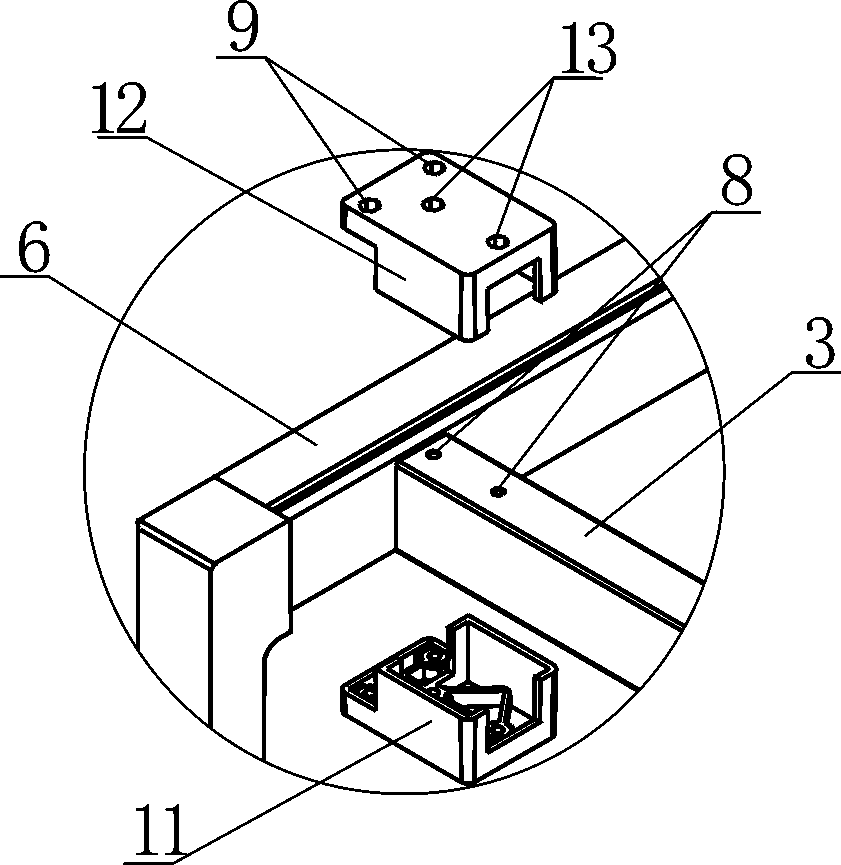

[0012] Such as figure 1 , 2 As shown, a frame includes a frame support A1, a frame support B2, a horizontal longitudinal beam 3 and a connecting assembly 4, and there are two horizontal longitudinal beams 3. Both ends of the horizontal longitudinal beam 3 are respectively connected to the beam 5 at the top of the frame support A and the beam 6 at the top of the frame support B through the connection assembly 4 . The bottoms of the frame support A1 and the frame support B2 are provided with leveling support feet 7 . The connecting assembly 4 is composed of an upper fixing buckle 12, a lower fixing buckle 11, a bolt 10, a nut and a screw, and the surface of the upper fixing buckle 12 and the lower fixing buckle 11 are provided with two through holes 13, so that Fixing holes 8 corresponding to the through holes 13 are provided on the horizontal stringer 3 and near the two ends of the horizontal stringer, and the upper fixing buckle 12 and the lower fixing buckle 11 clamp one en...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap