A miniature intelligent vacuum and pressurized air source module

A gas source and vacuum technology, which is applied to pressure vessels, fixed-capacity gas storage tanks, and equipment loaded into pressure vessels, etc. Large fluctuations and other problems, to achieve the effect of reducing frequent starts, improving service life, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The micro intelligent vacuum and pressurized air source module of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

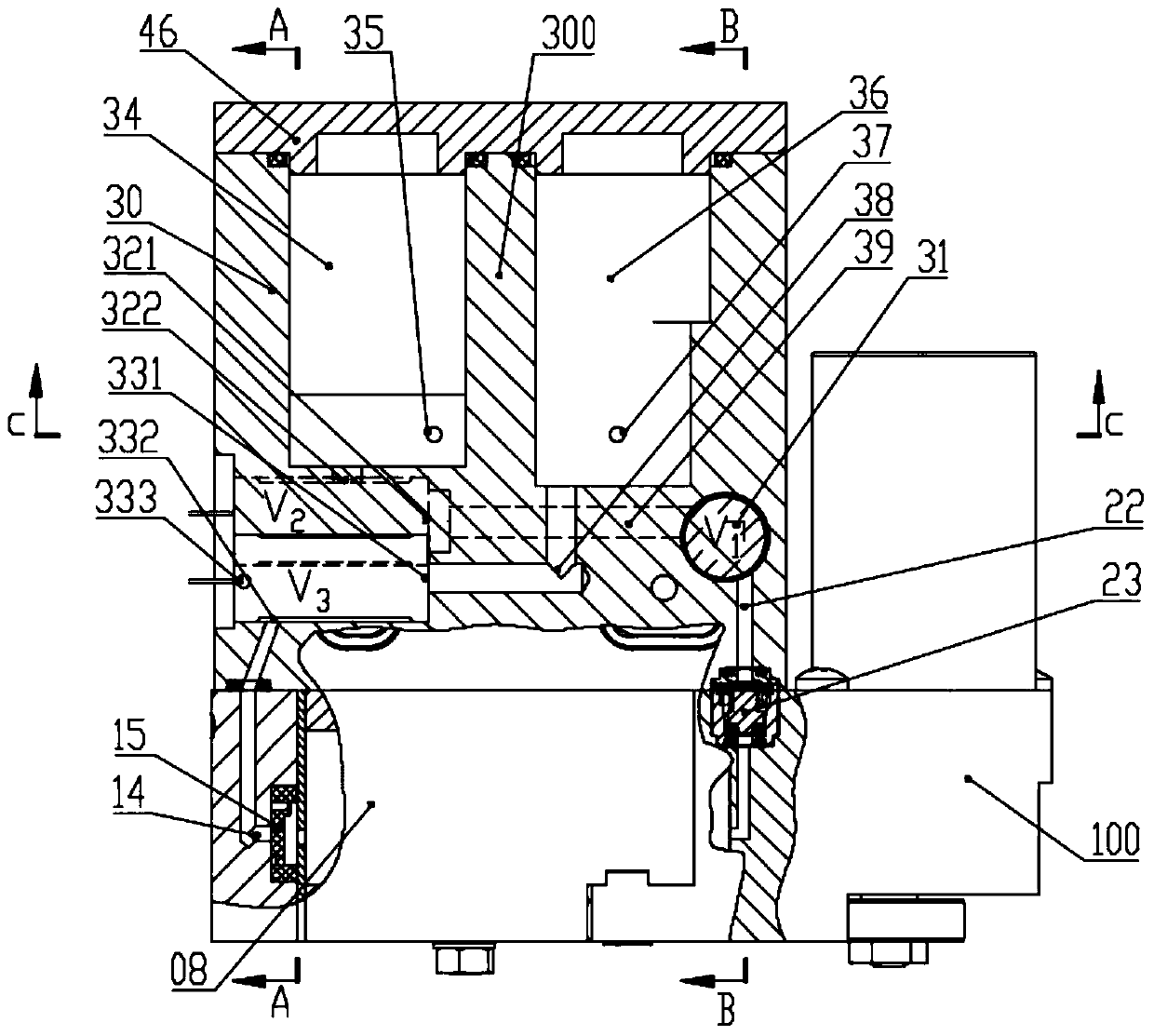

[0060] The miniature intelligent vacuum and pressurized air source module of the present invention includes two parts: an electric air pump 100 and an air source end block 300, see figure 1 shown, also includes control circuitry. The electric air pump 100 is a pressurized air pump, and the air source end block 300 communicates the electric air pump 100 with the outside world, and the control circuit (see Figure 4 ) controls the work of two parts. The following are introduced respectively:

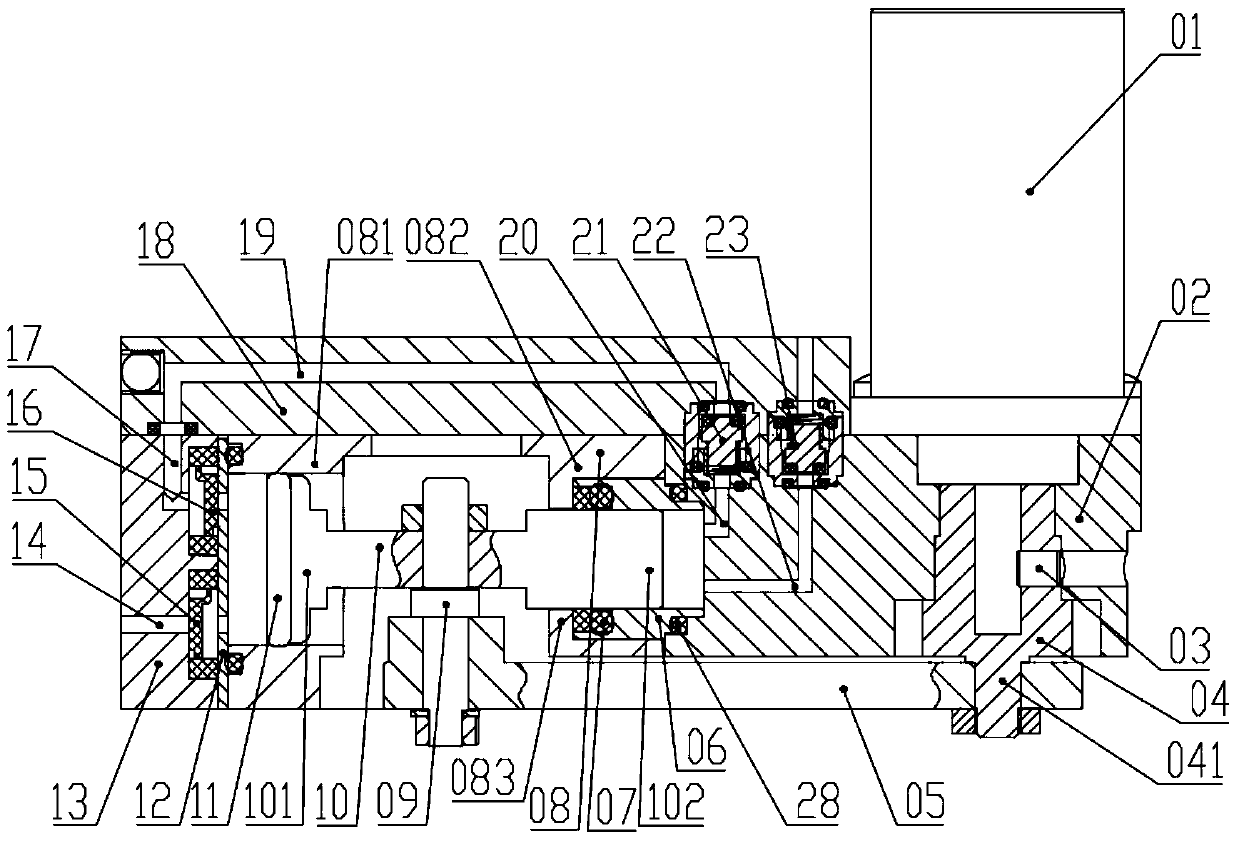

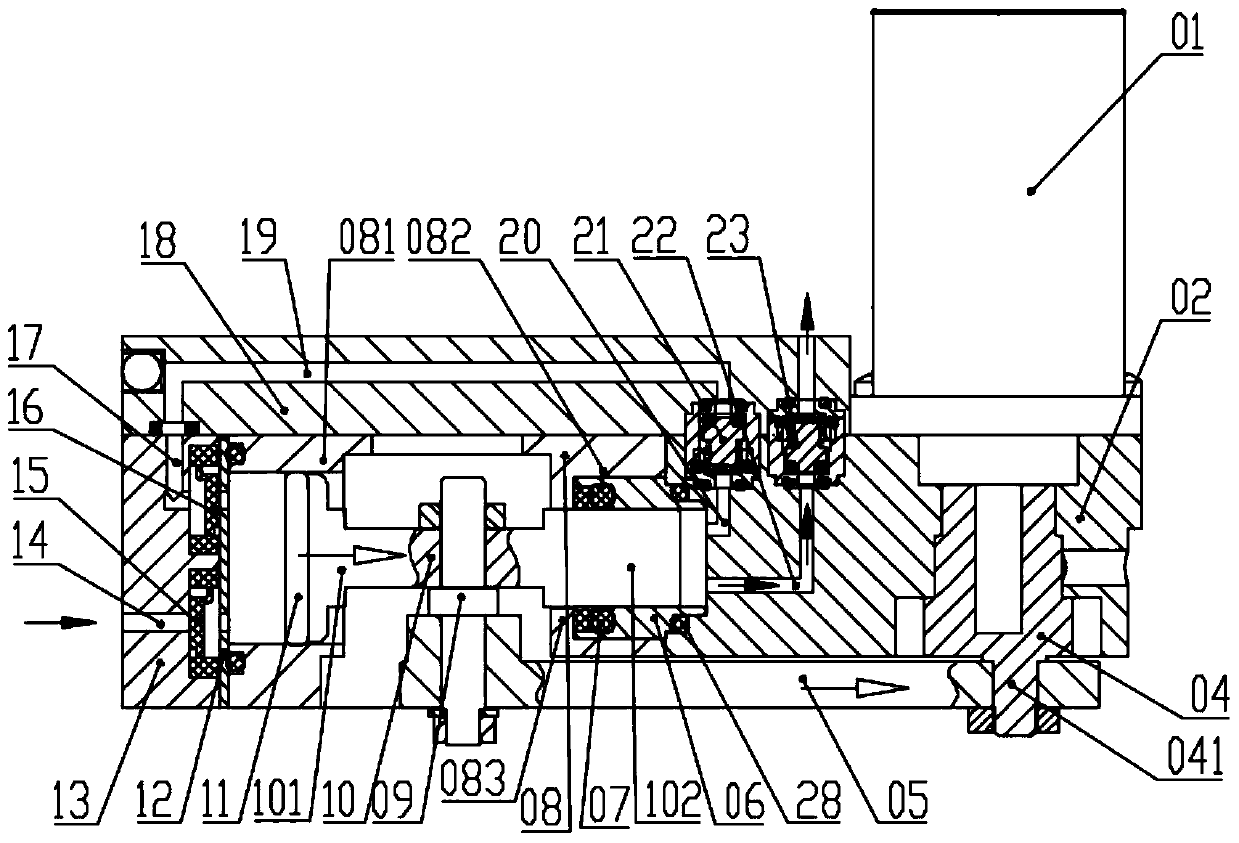

[0061] Electric air pump: cylinder-guided miniature booster electric air pump

[0062] The electric air pump of the present invention is a cylinder-guided miniature supercharged electric air pump, and its specific structure can be found in Figure 2-1 to Figure 2-3 , including motor 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com