A Method for Predicting Strip Edge Thinning During Cold Rolling in a Six-high Mill

A technology of six-high rolling mill and process strip, which is applied in the field of cold rolling, and can solve problems that have not yet been involved in thinning width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

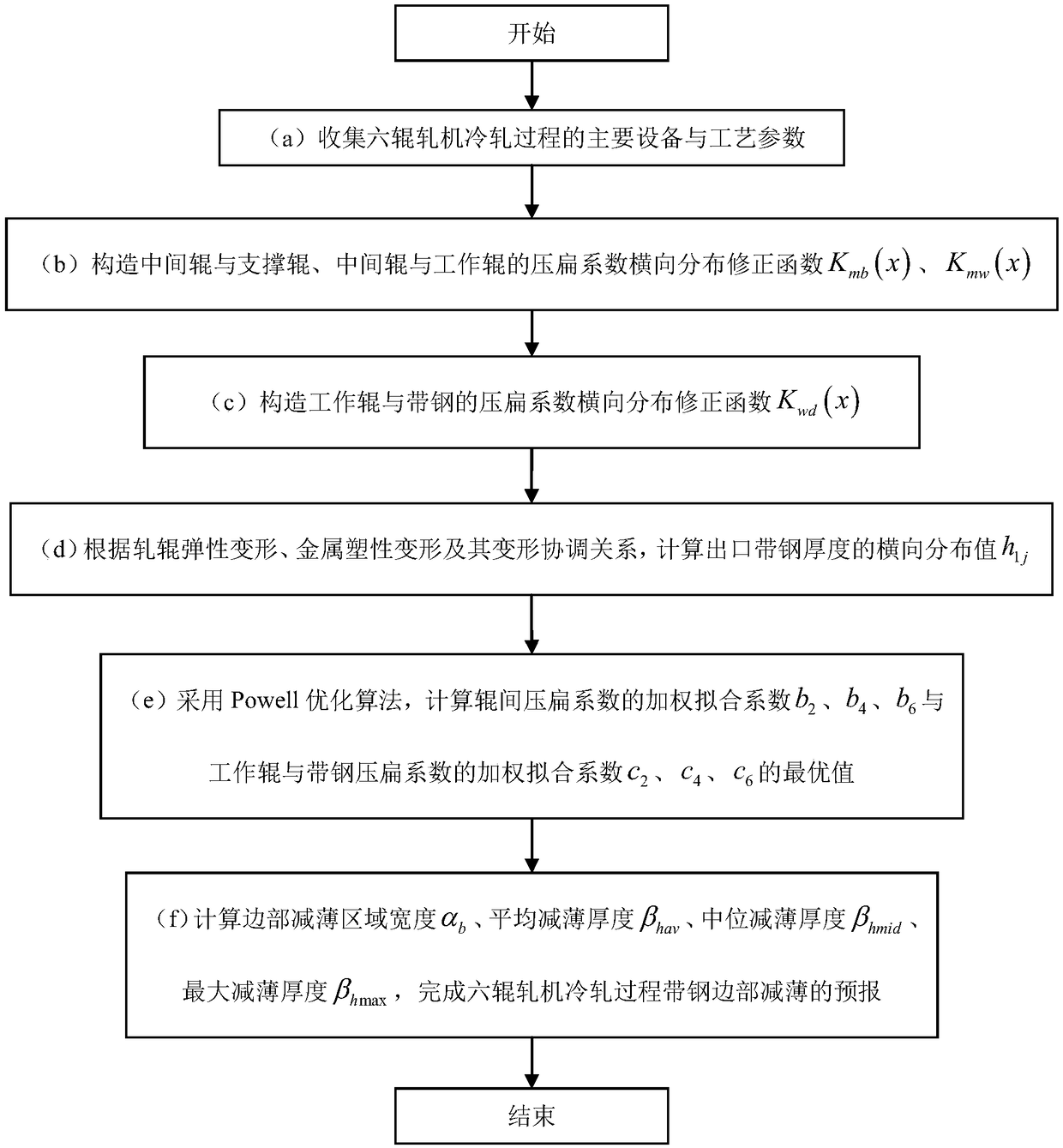

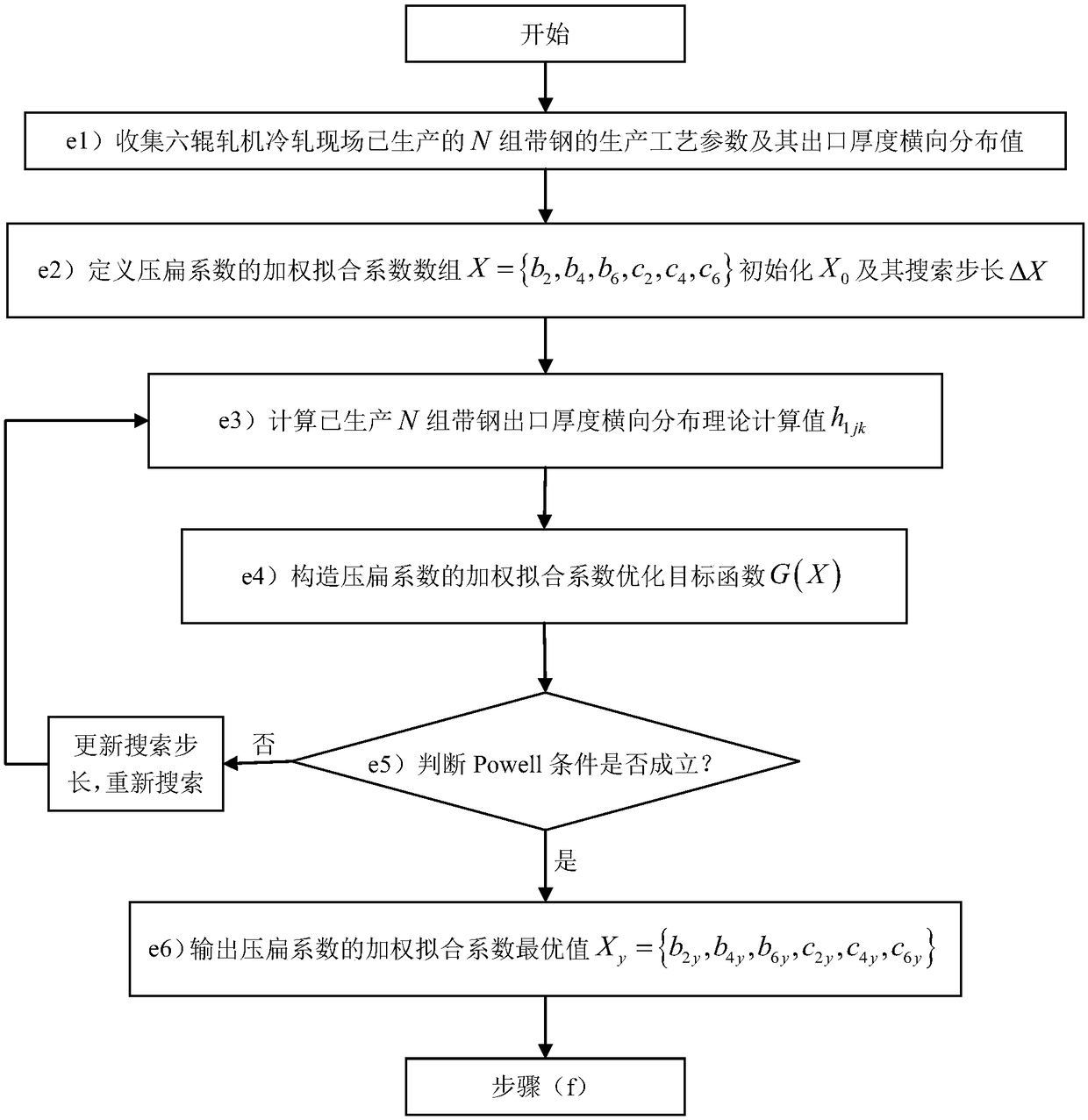

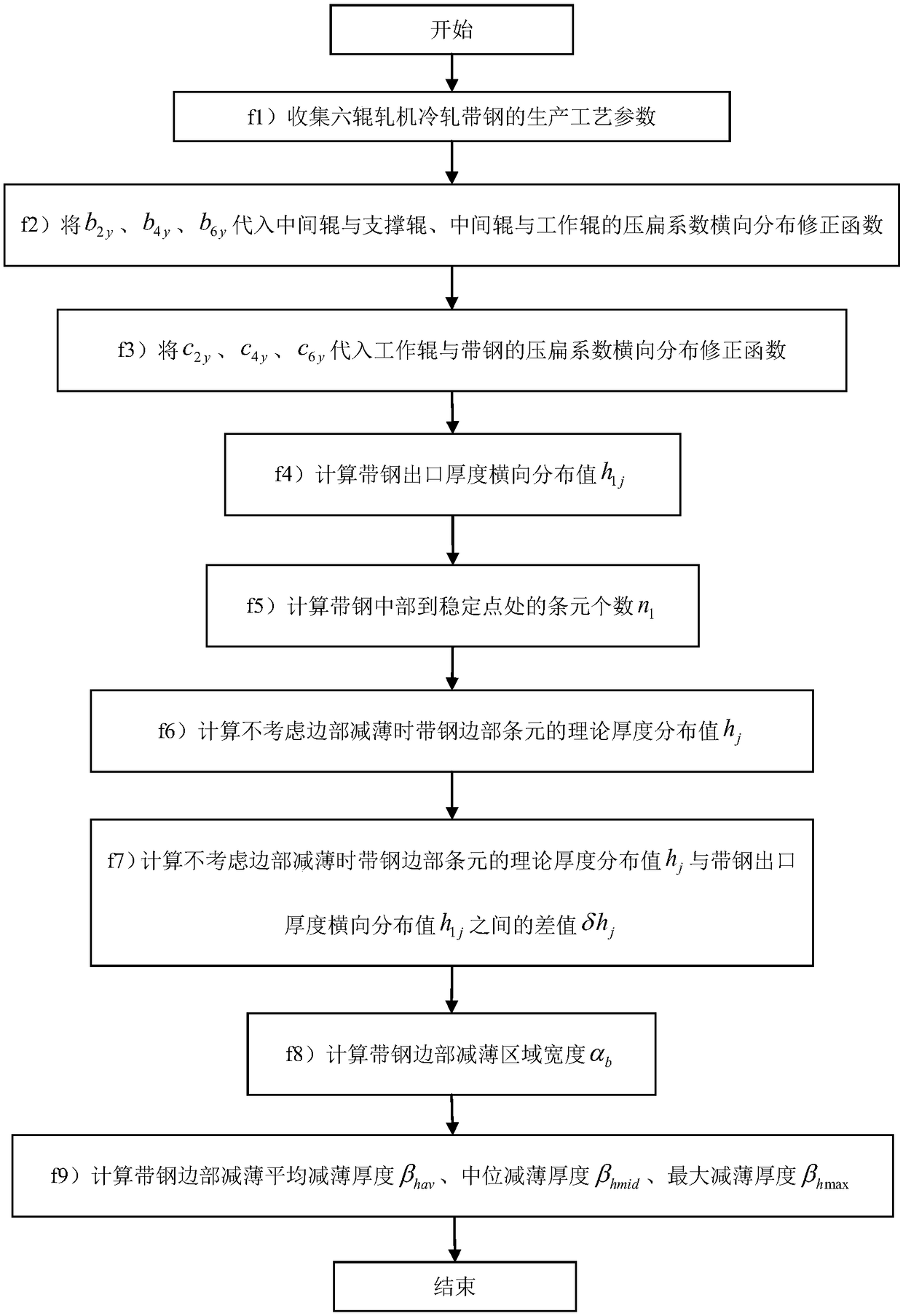

[0056] Taking a six-high rolling mill as an example, according to figure 1 The overall calculation flow chart of the strip edge thinning prediction method in the cold rolling process of the six-high mill is shown. First, in step (a), the main equipment and process parameters of the cold rolling process in the six-high mill are collected, including: work roll Roll radius R w =190mm, middle roll radius R m =210mm, backup roll radius R b =500mm; the elastic modulus E of the work roll w =210GPa, the elastic modulus E of the middle roll m =210GPa, Elastic modulus E of the backup roll b =210GPa; Poisson's ratio ν of work roll w = 0.3, Poisson's ratio ν of the middle roller m =0.3, Poisson’s ratio ν of the support roller b =0.3; Work roll body length L w =1420mm, middle roll body length L m =1420mm, back-up roller body length L b =1420mm; the distance between the work roll bending cylinder and the rolling center line l w =2500mm, the distance between the middle roll bendin...

Embodiment 2

[0093] First, in step (a), the main equipment and process parameters of the six-high rolling mill cold rolling process are collected, including: work roll radius R w =200mm, middle roll radius R m =215mm, backup roll radius R b =510mm; the elastic modulus E of the work roll w =210GPa, the elastic modulus E of the middle roll m =210GPa, Elastic modulus E of the backup roll b =210GPa; Poisson's ratio ν of work roll w = 0.3, Poisson's ratio ν of the middle roller m =0.3, Poisson’s ratio ν of the support roller b =0.3; Work roll body length L w =1420mm, middle roll body length L m =1420mm, back-up roller body length L b =1420mm; the distance between the work roll bending cylinder and the rolling center line l w =2500mm, the distance between the middle roll bending cylinder and the rolling center line l m =2500mm, the distance between the support roll lower cylinder and the rolling center line l b =2500mm.

[0094] Subsequently, in step (b), construct the flattening coe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com