Assembly tool for bread maker

A technology for assembling tooling and bread machines, applied in manufacturing tools, workpiece clamping devices, etc., can solve the problems of increased production costs, reduced assembly efficiency, lack of positioning of motors and mounting plates, etc., to reduce production costs, improve assembly efficiency, The effect of easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

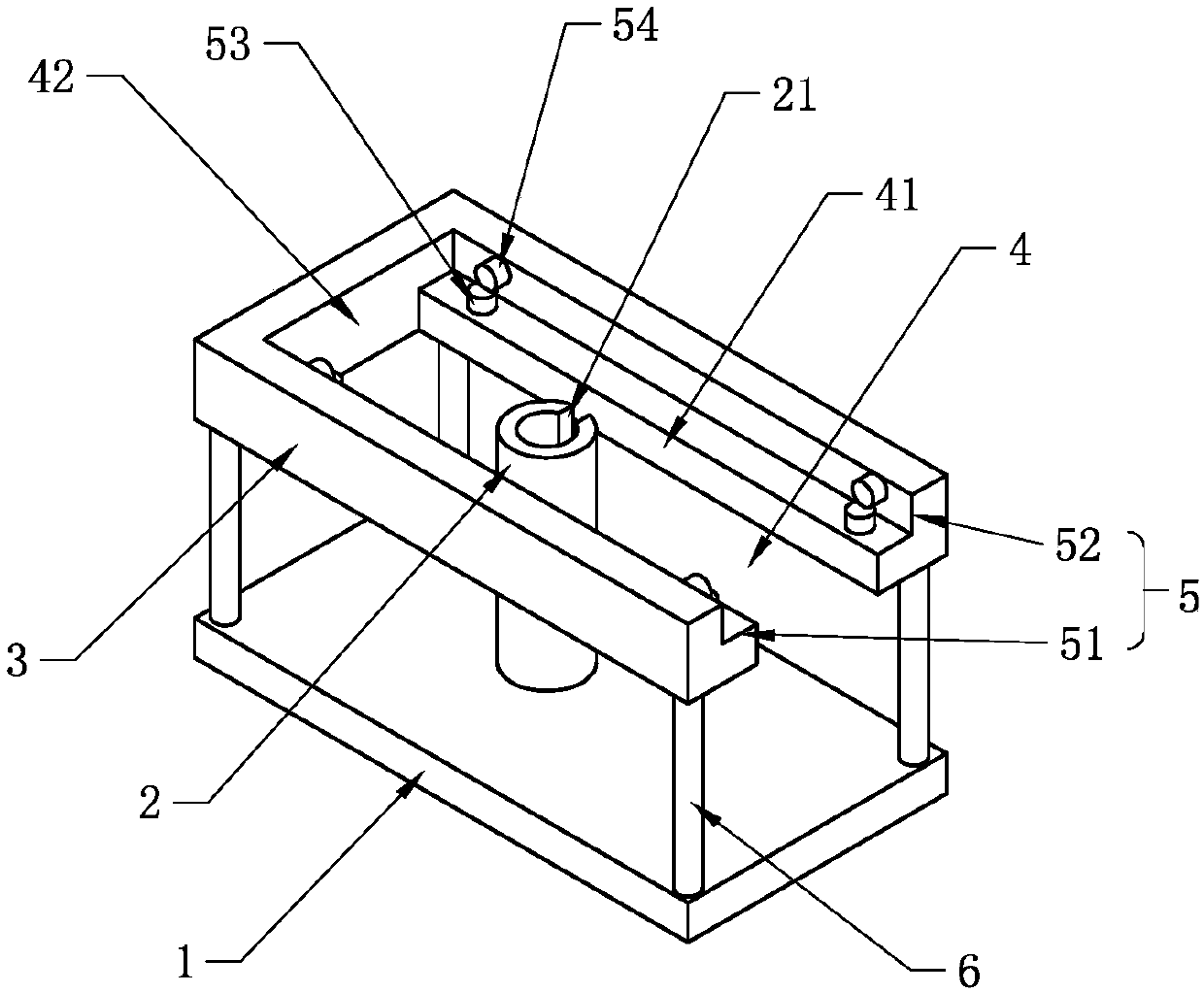

[0017] Such as figure 1 As shown, an assembly tool for a bread machine includes a base 1, the base 1 is provided with a first round tube 2 for positioning the motor and a first positioning plate 3 for positioning the mounting plate, and the first positioning plate 3 is arranged on the first round tube 2 The top of the first positioning plate 3 is provided with a first mouth 4 for accommodating the mounting plate, the first mouth 4 is arranged directly above the first round tube 2, and the first round tube 2 forms a stop for accommodating the motor In the cavity, the bottom of the first round tube 2 is connected to the base 1 , and the top end surface of the first round tube 2 is provided with a first recess 21 for accommodating motor wires.

[0018] In this embodiment, by setting the base 1, the first circular tube 2 for positioning the motor and the first positioning plate 3 for positioning the mounting plate are arranged on the base 1, so that the positions of the motor and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com