Metal mold with stable top reinforced heating function

A metal mold, a stable technology, applied in the direction of manufacturing tools, presses, etc., can solve the problems of insufficient heat transfer, flexible adjustment of the heating device, and exceeding the heating temperature, so as to increase temperature controllability, prolong thermal interaction time, Avoid the effect of excessive temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

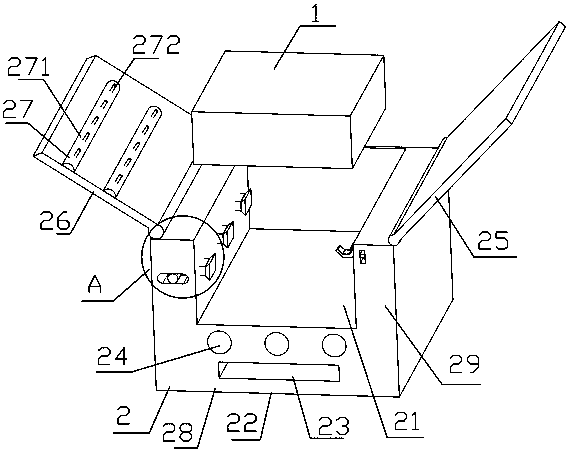

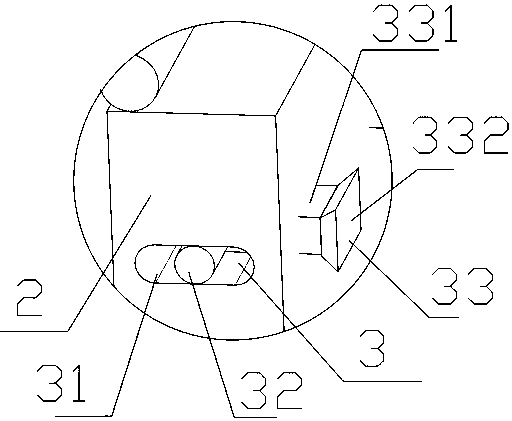

[0050] Example 1, such as figure 1 with figure 2 Shown: a metal mold with a stable top and enhanced heating, including a mold body 1 and a heating device 2 for heating the mold body 1. The heating device 2 is provided with an accommodation cavity 21 for accommodating the mold body 1. The heating device 2 includes The main body 28 and the two side extensions 29 extending vertically on both sides of the main body 28, the two side extensions 29 are respectively hinged with hinge plate one 25 and hinge plate two 26, hinge plate one 25 and hinge plate two The hinged plate 2 can be turned over to cover the accommodation cavity 21; the main body 28 includes a constant temperature heating portion 22, and the constant temperature heating portion 22 is provided with a main heating plate inlet 23 and an auxiliary pipeline inlet 24; the hinged plate 226 is provided with a point heating device 27.

[0051] During production and processing, the mold body 1 is put into the accommodating c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com