Train wheel lifting appliance

A wheel and spreader technology, applied in the field of wheel spreaders and train wheel spreaders, can solve the problems of difficult wheel rotation, small contact area of parts, wheel damage, etc., and achieve convenient and easy flow, coordinated connection, and firm clamping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

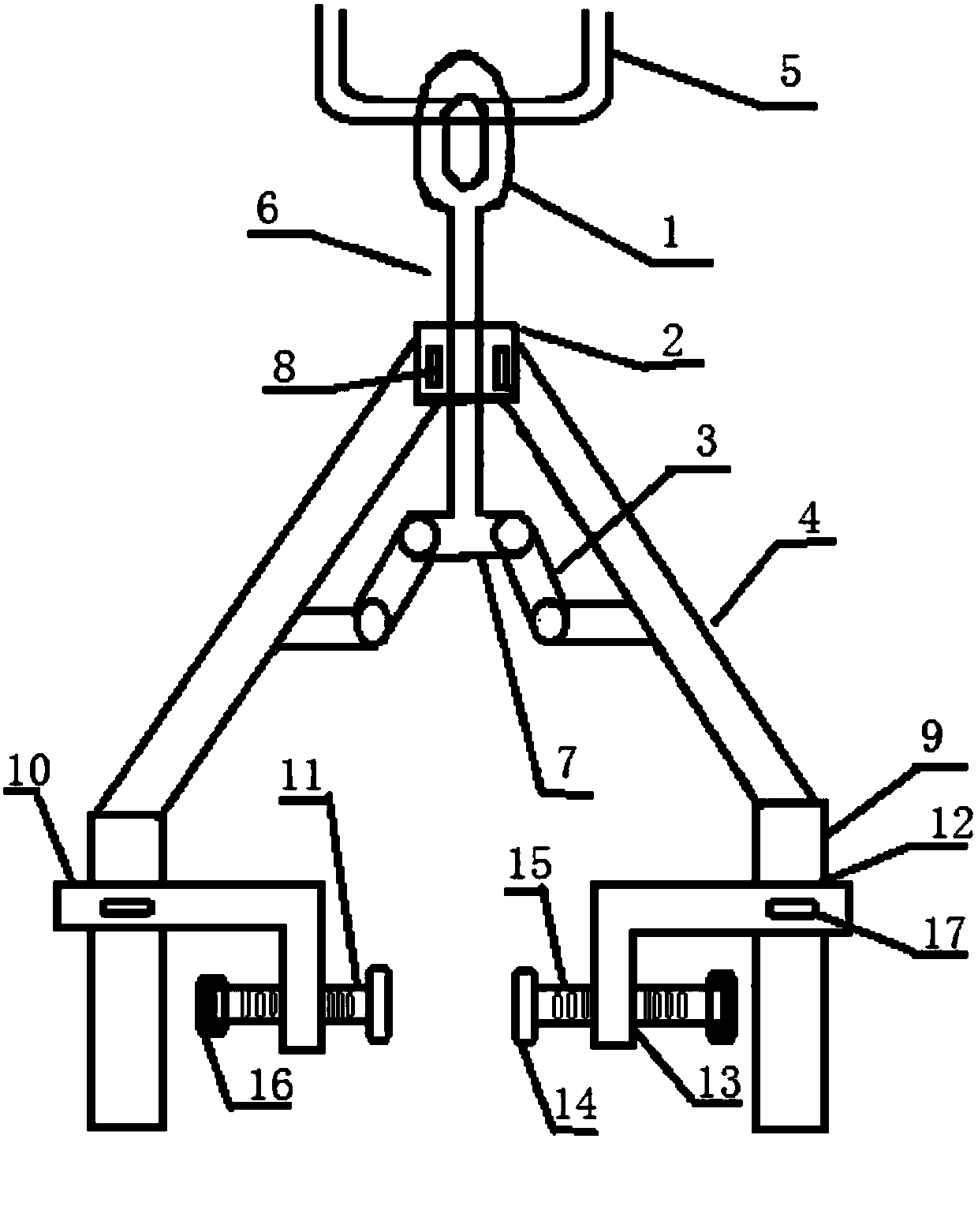

[0018] The technical scheme of a train wheel spreader provided by the present invention will be further described below in conjunction with the accompanying drawings, so that those skilled in the art can better understand the present invention and implement it.

[0019] see figure 1 , a train wheel spreader provided by the present invention, a train wheel spreader, includes a suspension chain 5 and a hanger 6, and is characterized in that: the hanger 6 includes a pull rod 1, a bracket 2, an adapter rod 3 and a support rod 4 , the upper end of the pull rod 1 is connected with the suspension chain 5, the bottom of the pull rod 1 extends to both sides a connecting platform 7 processed with a pin shaft connection hole, the support 2 is vertically provided with a pull rod connection hole, and the pull rod 1 passes through the pull rod of the support 2 Connecting holes, the upper end of the support rod 4 is connected in the support rod installation groove 8 at the lower end of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com