Bottom plate for a jacquard loom, its fabrication process, and weaving loom including such a plate

A technology for jacquard looms and healds, which is applied in the directions of jacquard looms, healds, textiles and papermaking, can solve problems such as increased price and cost of healds, and achieve the effect of low-strength friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

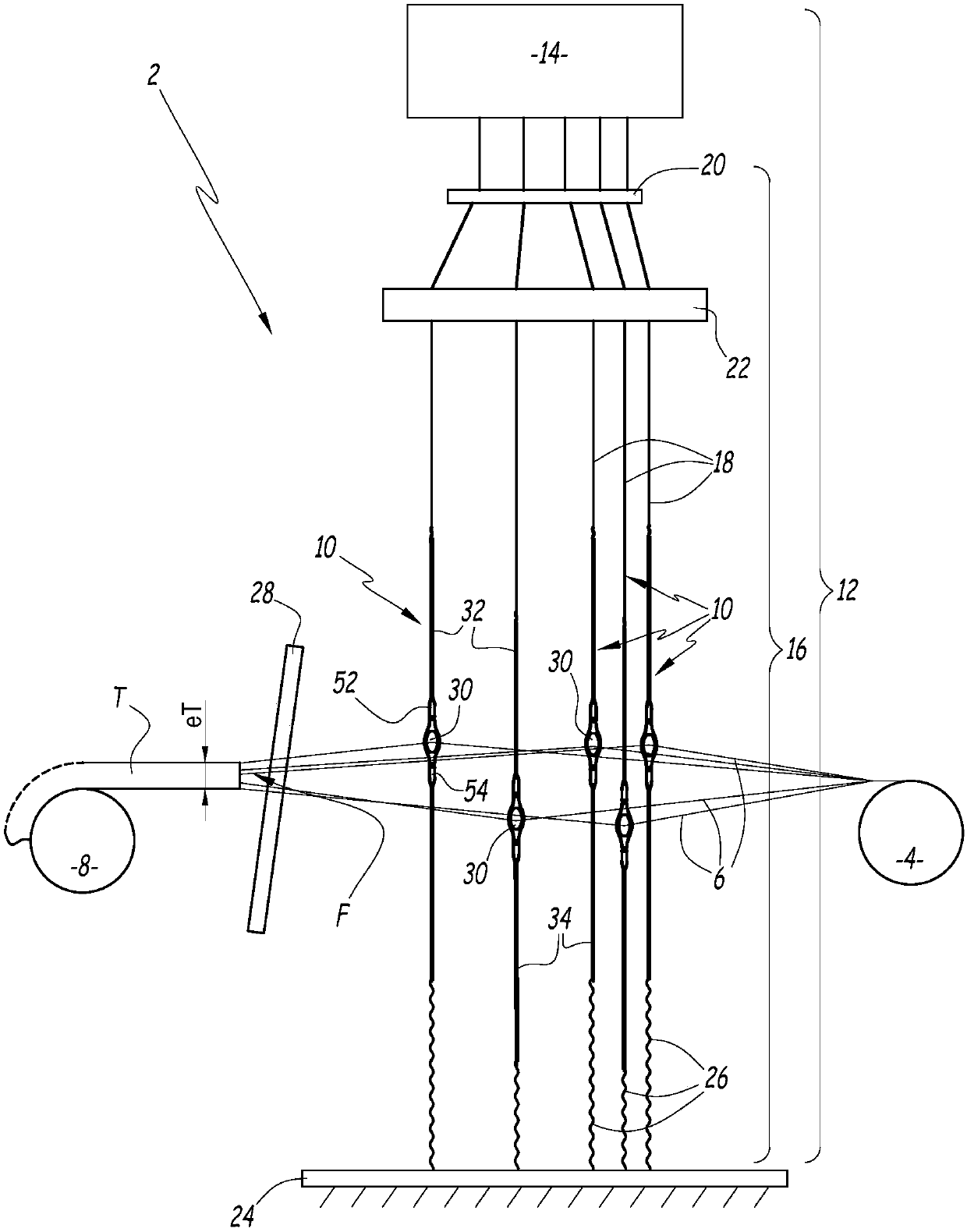

[0035] figure 1 The loom 2 shown in is configured to weave a fabric T having a thickness eT greater than 5 mm, for example about 10 mm.

[0036] The loom 2 comprises a warp beam 4 from which warp threads 6 are unwound, and a take-up roll 8 intended to receive a fabric T. As shown in FIG.

[0037] A system for inserting warp threads, not shown and known per se, gives the possibility of letting the warp threads enter a shed F defined between the warp threads 6 .

[0038] Each warp thread passes through the eyelet of the heddle 10, the vertical position of which is controlled by a mechanism 12 for forming the shed, which consists of a jacquard mechanism 14 and an arch 18 which passes through a guide plate 20, a mesh plate 22 and a return spring 26 Formation 16. Each heald 10 is suspended to the arch 18 and is connected at the lower part to the fixed frame 24 of the loom 2 by a return spring 26 which tends to pull the heald downwards against the pressure caused by the correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com