High-pressure-resistant tooling joint

A high-pressure, tooling technology, applied in the direction of pipes/pipe joints/fittings, flange connections, through components, etc., can solve the problems of inability to meet high pressure and work strength requirements and cannot be recycled and reused, and achieve convenient recycling and reuse. , The effect of easy sealing and fixing operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

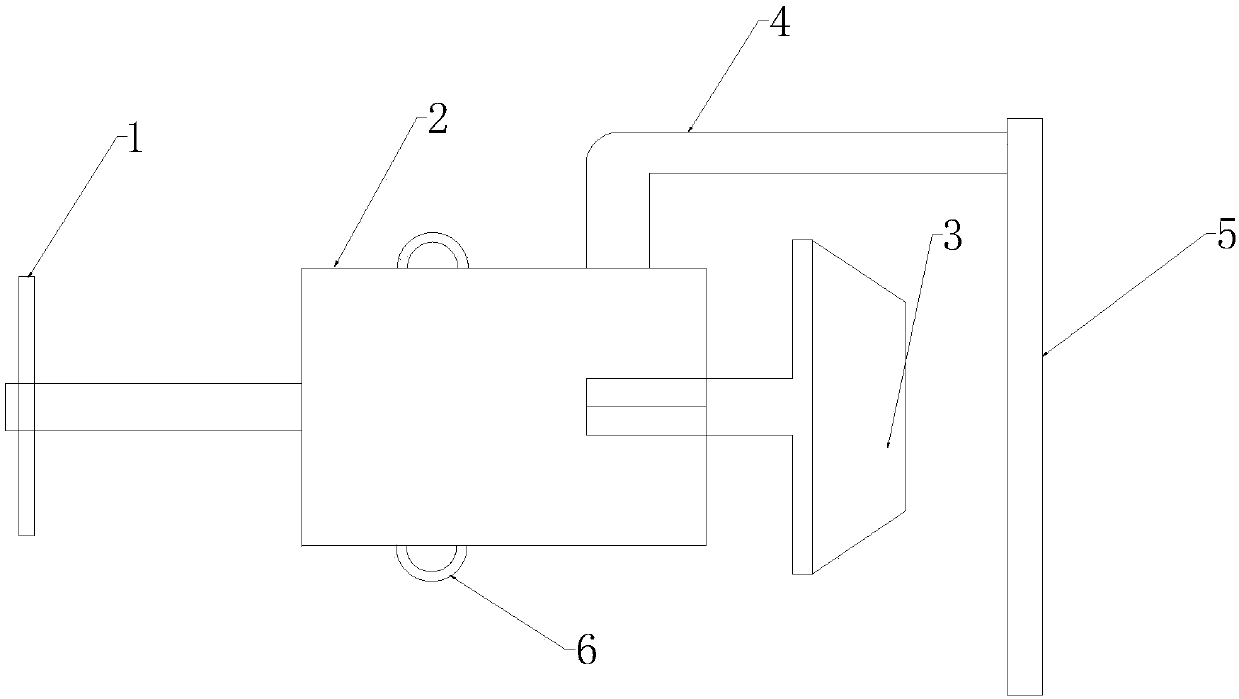

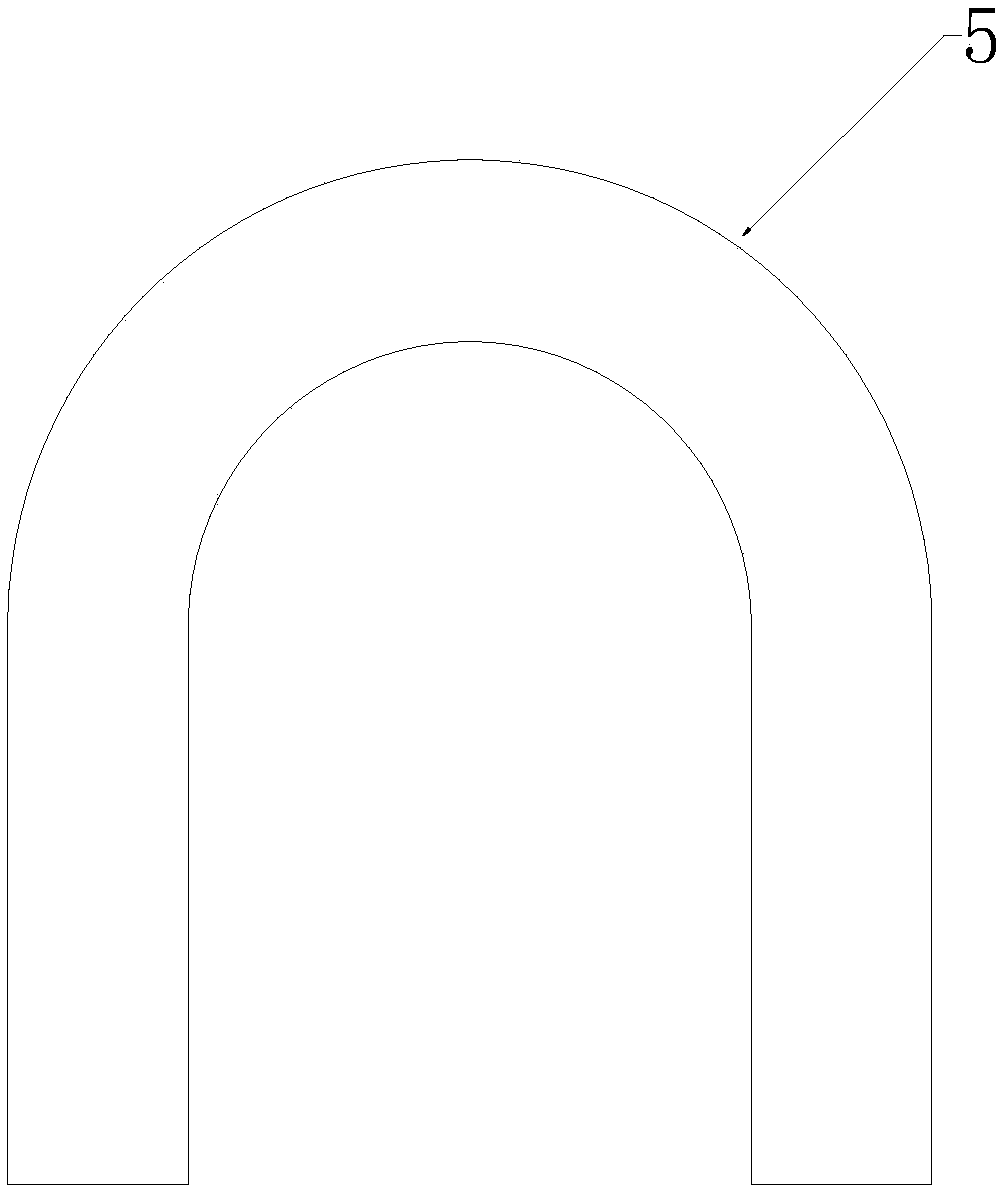

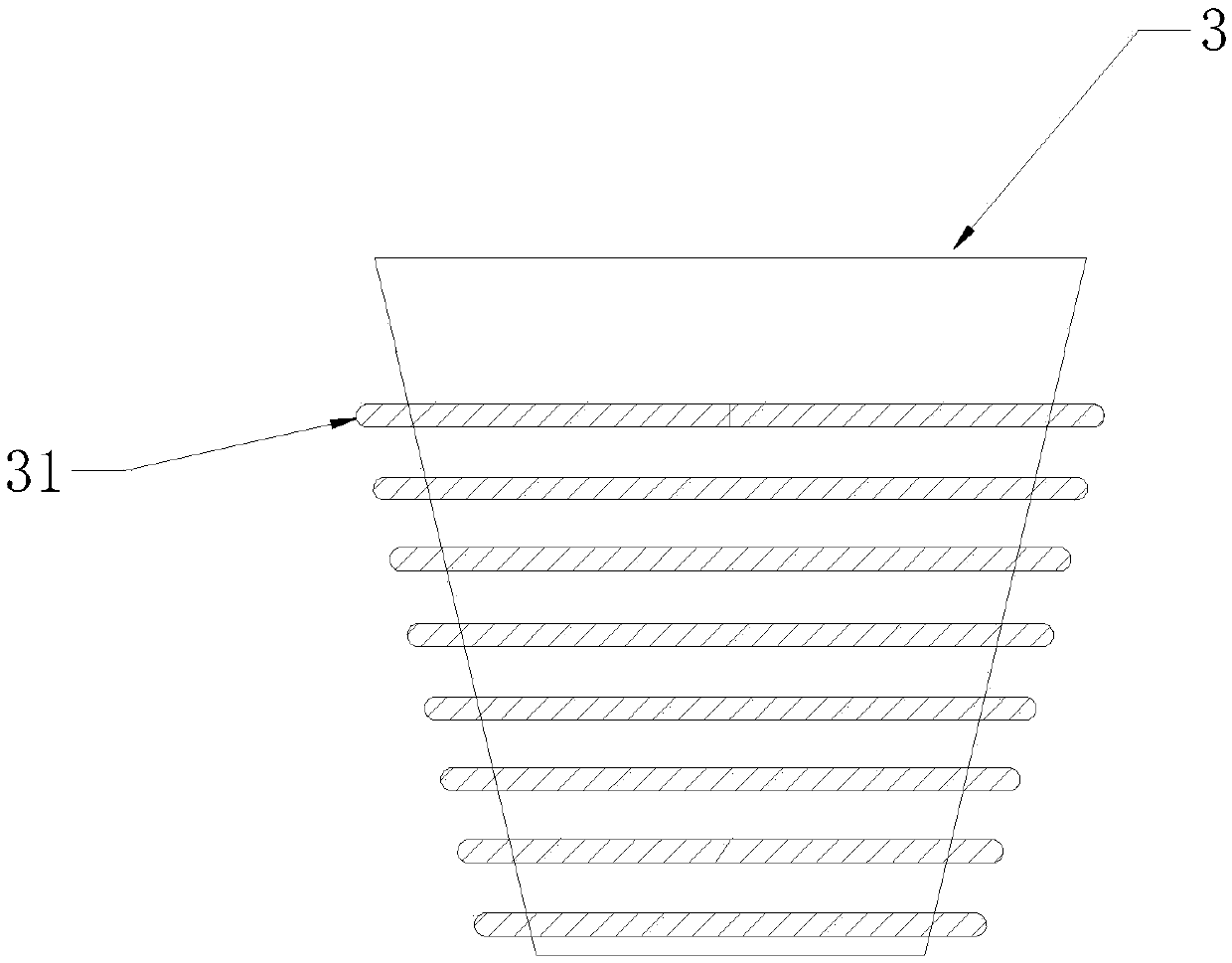

[0023] Such as figure 1 As shown, this embodiment provides a high-pressure resistant tool joint for sealing and fixing the pipe, including a transmission mechanism 2, and one end of the transmission mechanism 2 is movably connected with a sealing plug 3 for sealing the end of the pipe The other end of the transmission mechanism 2 is movably connected with an adjustment wrench 1 for driving the sealing plug 3 to move back and forth, and also includes a flange clamp 5 for fixing the pipe, and the flange clamp 5 passes through a The connecting arm 4 is fixed on the transmission mechanism 2 , the sealing plug 3 is arranged relatively parallel to the flange plate 5 , and at least two hanging lugs 6 are arranged on the transmission mechanism 2 .

[0024] Specifically, during use, the ship pipe to be sealed and fixed can be snapped into the flange plate 5 through the U-shaped opening. Since the two ends of the pipe are provided with flange joints, the diameter of the flange joint is ...

Embodiment 2

[0035] The difference between this embodiment and Embodiment 1 is that the number of the hanging lugs 6 is four, which are respectively arranged on the four sides of the transmission mechanism 2, and two of a pair of sides are used to connect the two sides of the present invention. The high-pressure tooling joints are suspended and fixed, and the other two are fixed to the wall through the fixing chain to enhance the sealing effect, prevent falling off, and further improve the fixing and sealing effect.

[0036] Other technical features of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com