Storage battery electrode plate curing system and method

A technology of plate curing and battery, applied in the direction of lead-acid battery electrodes, etc., can solve the problems of difficulty in ensuring moisture, long time consumption of lead-acid battery plate curing, affecting the quality of plates, etc., to achieve good air circulation effect, avoid The effect of cracking on the surface of the plate and improving the environment of the curing chamber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

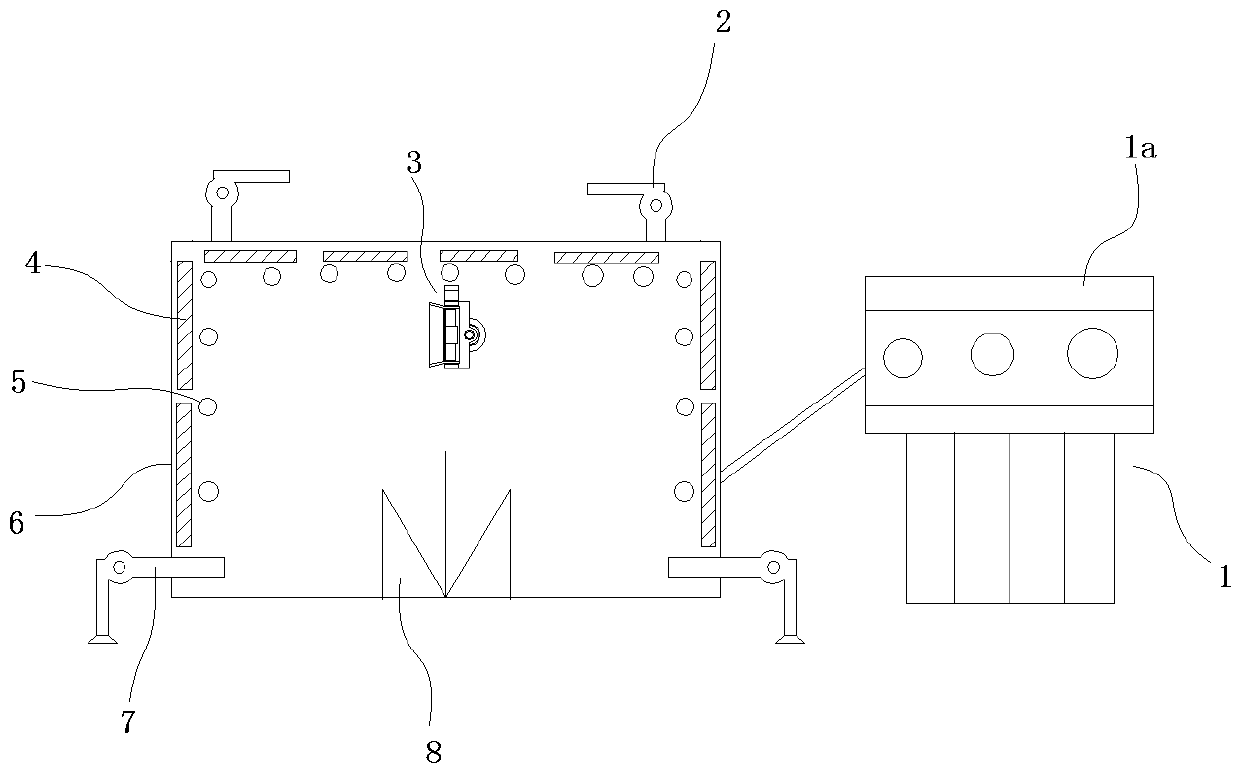

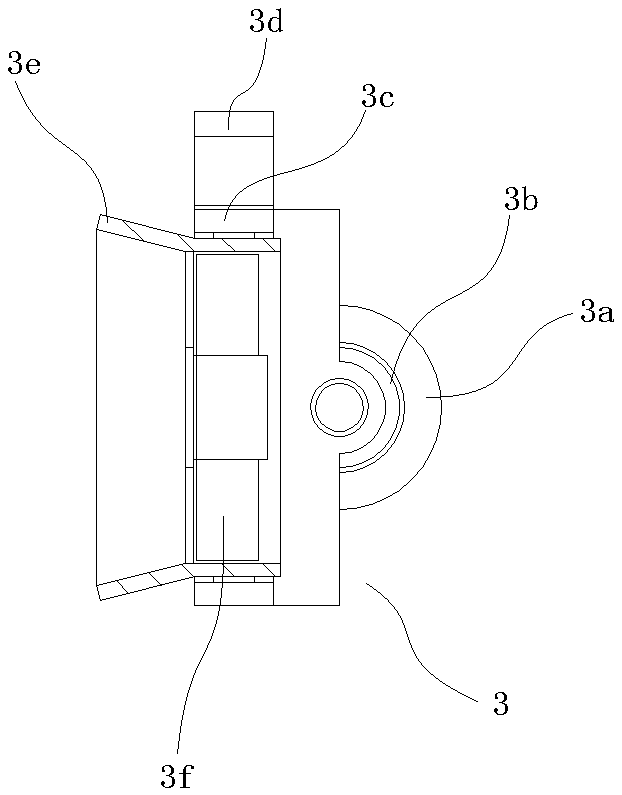

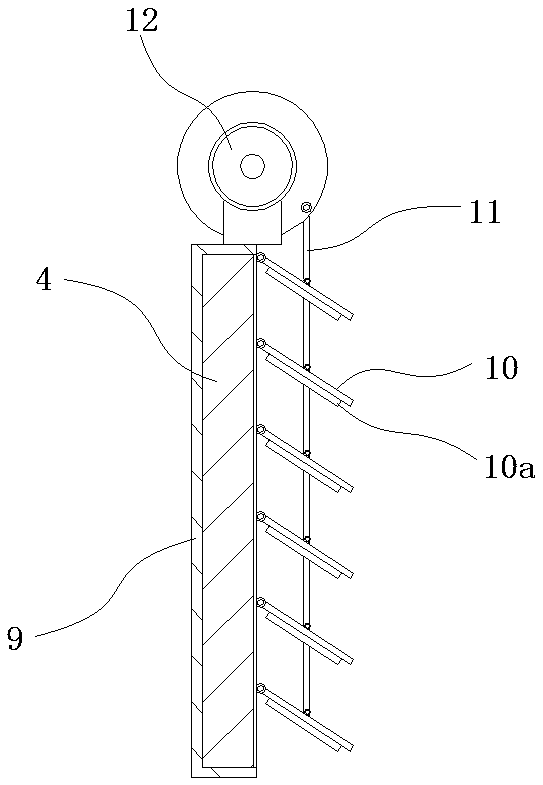

[0025] like figure 1 In the illustrated embodiment, a storage battery plate curing system includes a curing chamber 6 and a control module 1, wherein the control module includes a steam heater 1a, and a steam pipe is provided at the outlet of the steam heater, and the steam pipe communicates with the curing chamber, Heat energy and moisture can be provided to the interior of the curing chamber, and the position of the steam pipe communicating with the curing chamber is close to the bottom of the curing chamber, so that the hot air can be evenly distributed in the curing chamber after entering. The side wall and the top of the curing chamber are provided with a number of water-absorbing sponges 4, and the curing chamber is provided with a spray module 5 outside the water-absorbing sponges.

[0026] The curing chamber is provided with an airtight door 8, and the outside of the curing chamber is provided with a blower 7 for air intake into the curing chamber and an air extractor ...

Embodiment 2

[0030] like figure 1 In the illustrated embodiment, a storage battery plate curing system includes a curing chamber 6 and a control module 1, wherein the control module includes a steam heater 1a, and a steam pipe is provided at the outlet of the steam heater, and the steam pipe communicates with the curing chamber, Heat energy and moisture can be provided to the interior of the curing chamber, and the position of the steam pipe communicating with the curing chamber is close to the bottom of the curing chamber, so that the hot air can be evenly distributed in the curing chamber after entering. The side wall and the top of the curing chamber are provided with a number of water-absorbing sponges 4, and the curing chamber is provided with a spray module 5 outside the water-absorbing sponges.

[0031] The curing chamber is provided with an airtight door 8, and the outside of the curing chamber is provided with a blower 7 for air intake into the curing chamber and an aspirator for ...

Embodiment 3

[0048] A battery plate curing method, comprising the following steps:

[0049] a. Send the polar plate into the curing chamber, close the airtight door, start the control module, and the steam heater in the control module is connected with the curing chamber to heat the curing chamber and provide part of the humidity;

[0050] b. When the curing chamber is heated to 45°C, start the air circulation module to make the air in the curing chamber flow and circulate, and the control module continues to heat the curing chamber;

[0051] c. When the curing chamber is heated to 70°C, start the blower and exhaust fan in sequence, and the air circulation module continues to operate to realize the flow and circulation of air inside and outside the curing chamber. The control module continues to heat the curing chamber until the plates are completely cured.

[0052] In step b and step c, when the humidity in the curing chamber is lower than a predetermined value, the spray module is activa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com