Connecting Element For Contacting A Shielding Of A Power Cable

A technology for connecting elements and contact elements, applied in the directions of electrical elements, conductive connections, electrical connection seats, etc., can solve the problems of high rigidity, deteriorated electrical contact, etc., and achieve the effect of flexible structure, low ohmic resistance, and simple outline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

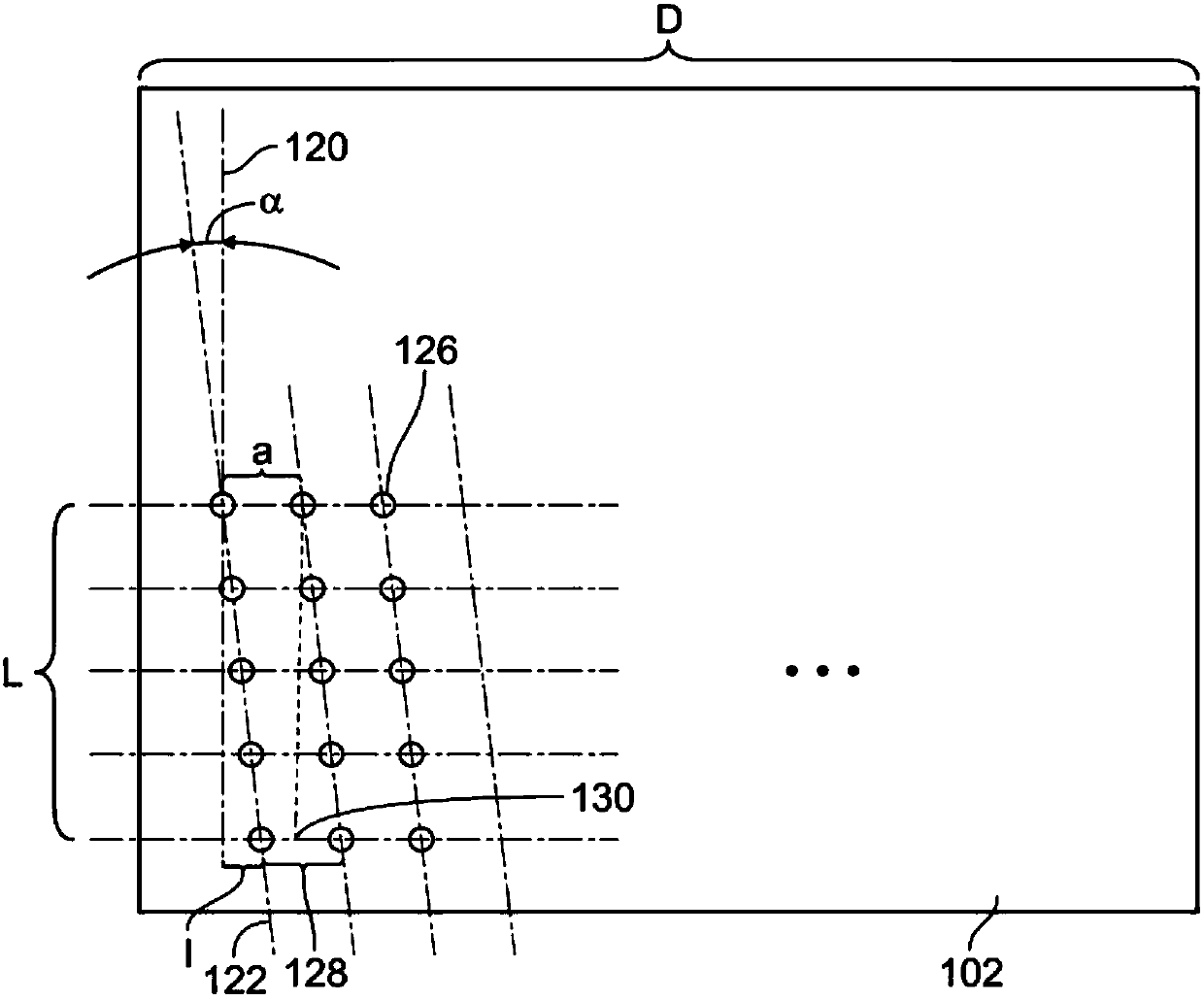

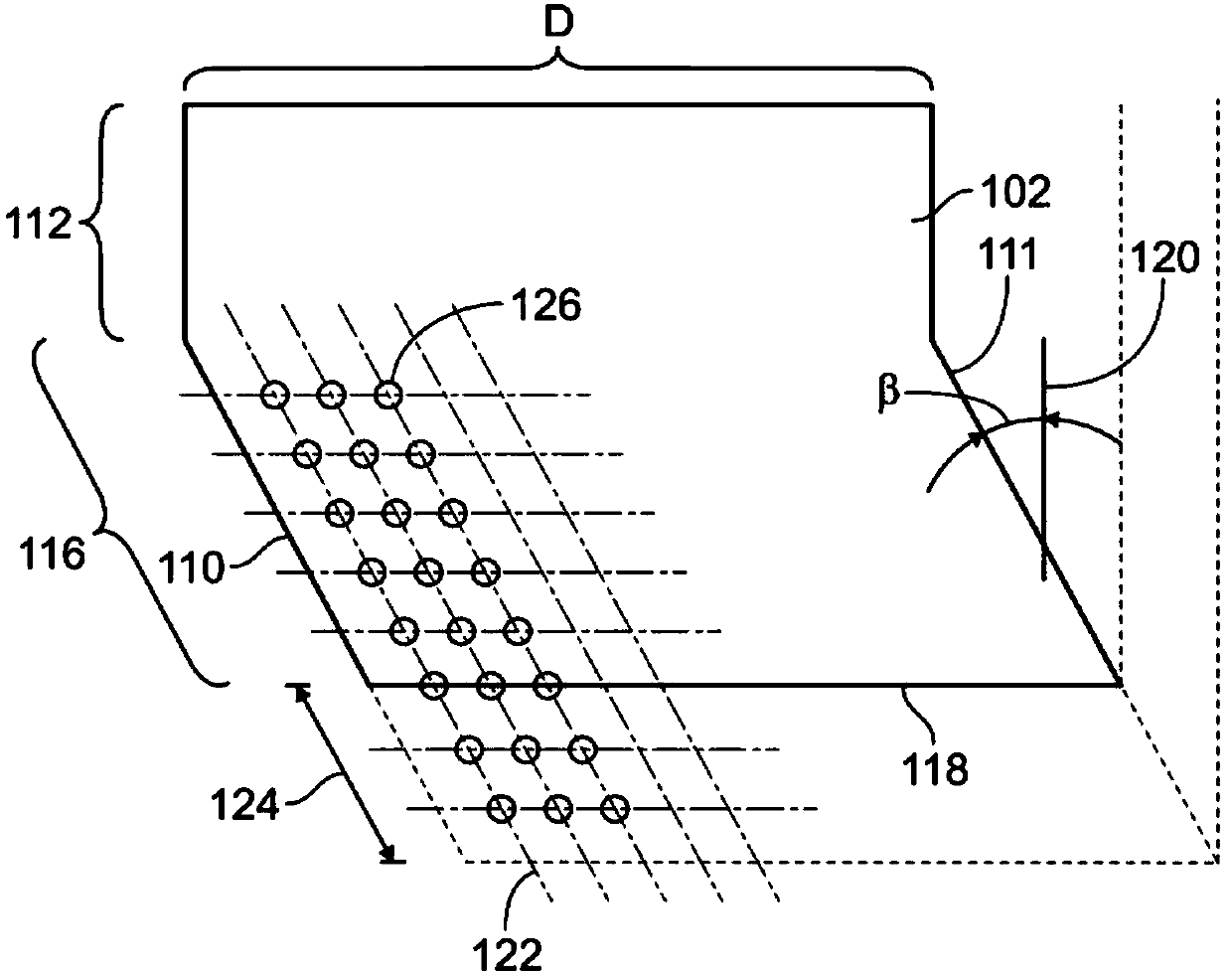

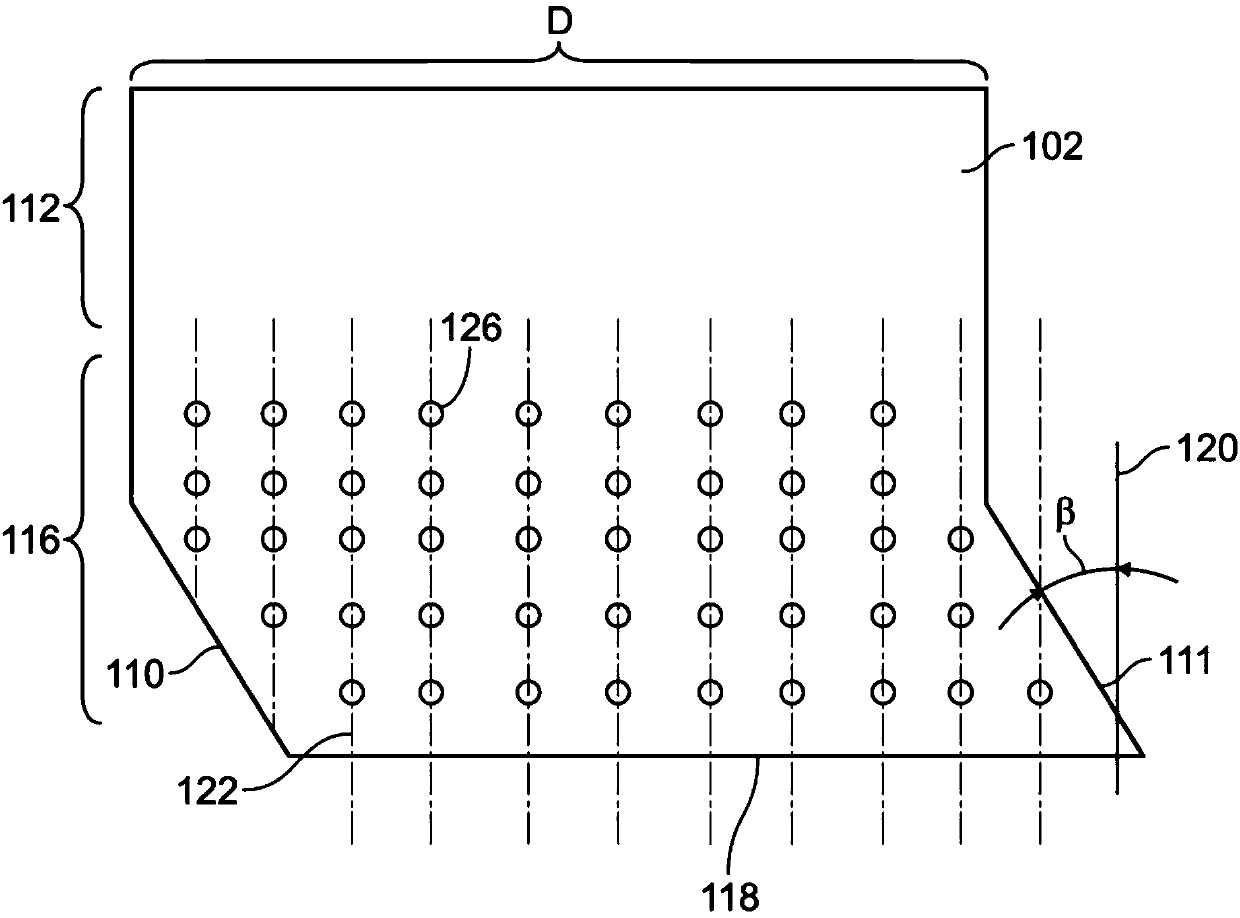

[0053] The invention will now be further explained with reference to the accompanying drawings, first with reference to figure 1 . figure 1 Shown according to the present invention as a connecting element 100 ( Figure 5 A plan view of a part of the contact element 102 shown in FIG.

[0054] now refer to figure 1 , the contact element 102 according to the first aspect of the invention will be explained. According to this embodiment, the protrusions 126 are arranged in rows 122 at an angle α to the longitudinal axis 120 of the cable. The shape of the protrusion 126 can vary. The standard shape has a square profile and four triangular uprights (see Figure 8 ). exist Figures 1 to 4 In , protrusions are schematically represented by circular outlines. However, it needs to be recognized that this form is merely an example of forming the protrusion 126 .

[0055] Furthermore, it is expected that the connection element 100 according to the present invention can be used w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com